Lightweight mulch recovery machine for wheat field

A recycling machine, portable technology, applied in the direction of plant protection cover, etc., can solve the problems of lack of mulching film recycling in wheat fields, difficult mulching film recycling in wheat fields, time-consuming operation efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

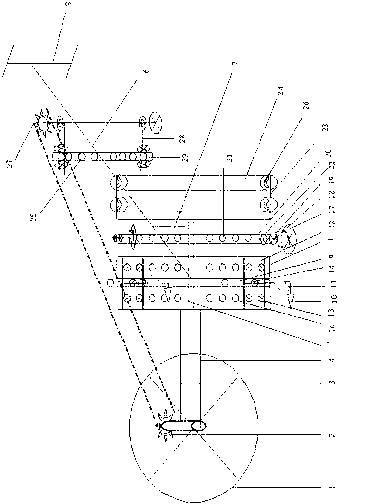

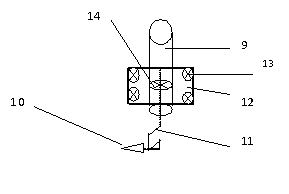

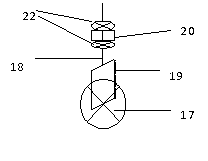

[0016] The frame includes a front fork (4), a front fork handle (5), an oblique upright rod (6), a pull rod (7) and an I-shaped handrail (8); 6) Weld with the front fork handle (5); the ground wheel (1) is installed at the front end of the front fork (4); the front fork handle (5) is equipped with a film removing device and a film feeding device from front to back; a film rolling device Installed on the adjustment plate C (29) welded on the inclined pole (6); the middle point of the adjustment plate A (15) is welded on the front part of the front fork handle (5), and the left and right sides of the adjustment plate A (15) are respectively installed There is a set of film-removing components; the middle point of the adjustment plate B (20) is welded to the middle of the front fork handle (5), and a set of film-pressing components are installed on the left and right sides of the adjustment plate B (20); the film-passing bracket (23) is shaped like a U Font, the midpoint of its t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com