Oral quick-dissolving film preparation and preparation method thereof

An oral instant film agent and oral instant film technology, applied in the field of pharmaceutical preparations, can solve the problems of no oral instant film and achieve the effects of shortening the disintegration time, solving the long disintegration time, and accelerating the disintegration time limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

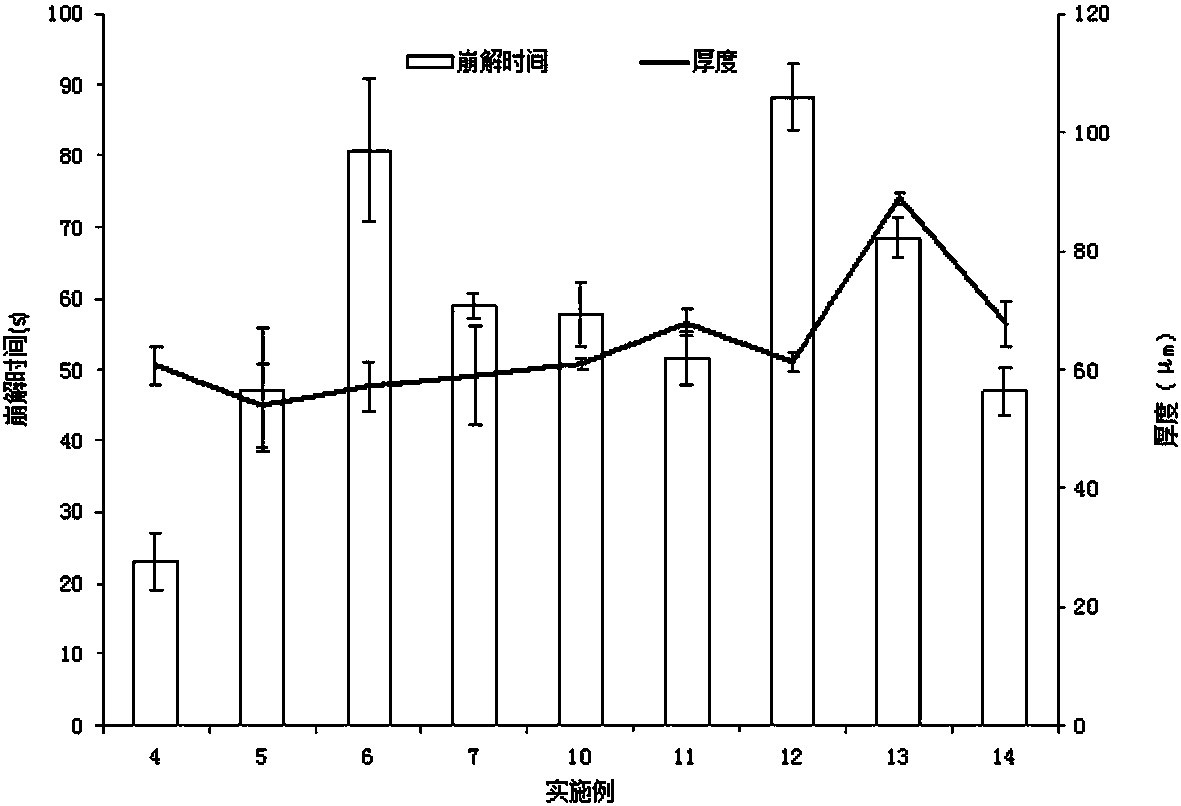

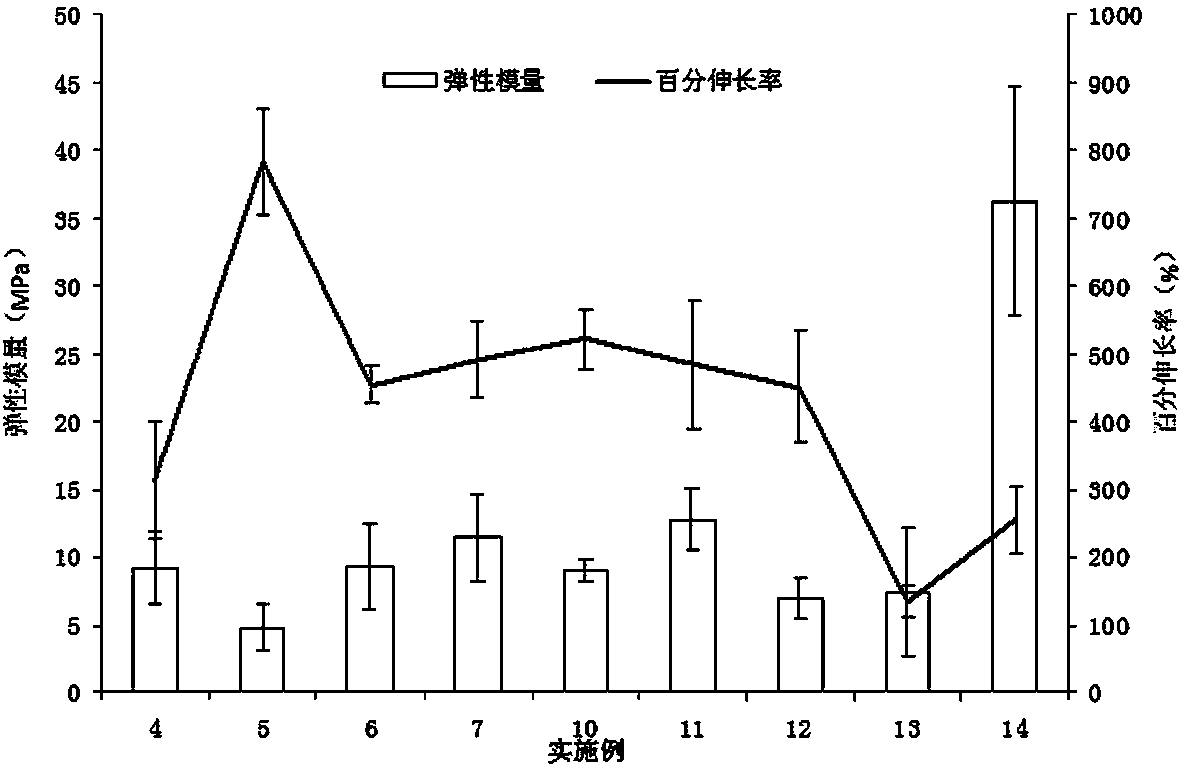

Examples

Embodiment 1

[0034] Polyvinyl alcohol 1788 1000mg

[0035] Macrogol 4000 250mg

[0036] Sodium Alginate 100mg

[0037] Purified water 20mL

[0038] First add the above amount of polyvinyl alcohol into purified water under stirring, and dissolve in a water bath to obtain a gel solution, then add polyethylene glycol 4000 and sodium alginate, and stir to dissolve. Allow the prepared solution to stand or sonicate to remove air bubbles. Spread the solution evenly on 15×15cm 2 Stainless steel plate, 40-60 ℃ blast heating and drying for 2 hours. Remove the film and cut it to get the film agent, which is white, has poor release performance, poor toughness and is brittle.

Embodiment 2

[0040] Polyvinyl alcohol 1788 1000mg

[0041] Macrogol 1000 250mg

[0042] Sodium Alginate 100mg

[0043] Purified water 20mL

[0044] First add the above amount of polyvinyl alcohol into purified water under stirring, and dissolve in a water bath to obtain a gel solution, then add polyethylene glycol 1000 and sodium alginate, and stir to dissolve. Allow the prepared solution to stand or sonicate to remove air bubbles. Spread the solution evenly on 15×15cm 2 Stainless steel plate, 40-60 ℃ blast heating and drying for 2 hours. Remove the film and cut it to get the film agent, which is transparent and has poor release performance.

Embodiment 3

[0046] Polyvinyl alcohol 1788 1000mg

[0047] Glycerin 250mg

[0048] Sodium Alginate 100mg

[0049] Purified water 20mL

[0050] First add the above-mentioned amount of polyvinyl alcohol into purified water under stirring, and dissolve in a water bath to obtain a gel solution, then add glycerin and sodium alginate, and stir to dissolve. Allow the prepared solution to stand or sonicate to remove air bubbles. Spread the solution evenly on 15×15cm 2 Stainless steel plate, 40-60 ℃ blast heating and drying for 2 hours. Remove the film and cut it to get the film agent. The film is transparent, good release performance, flexible and sticky on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com