Drive device of electric motor car

A technology for electric motorcycles and driving devices, which is applied to transmission devices, wheel transmission devices, gear transmission devices, etc., can solve problems such as insufficient shift fork fluctuations, poor wheel bearing bearing capacity, and troublesome transmission maintenance, so as to avoid accidental damage. , Small power loss, compact and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

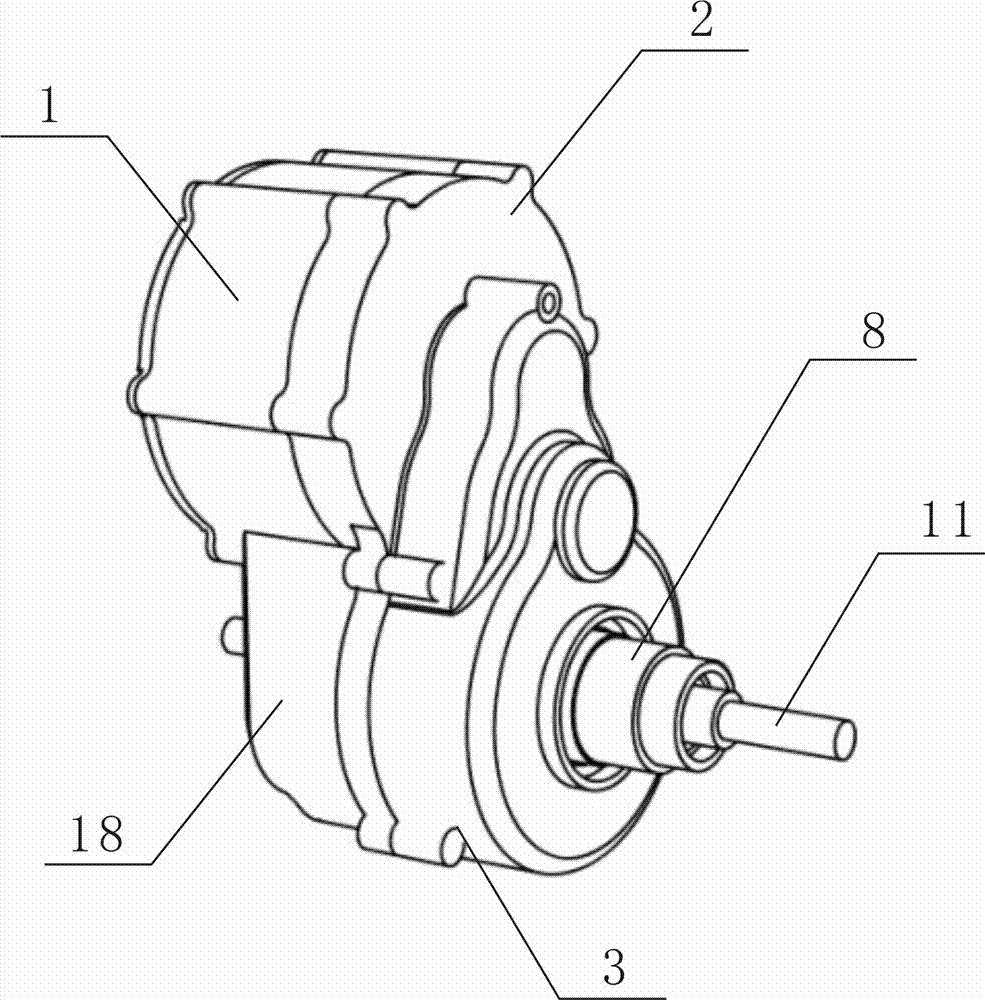

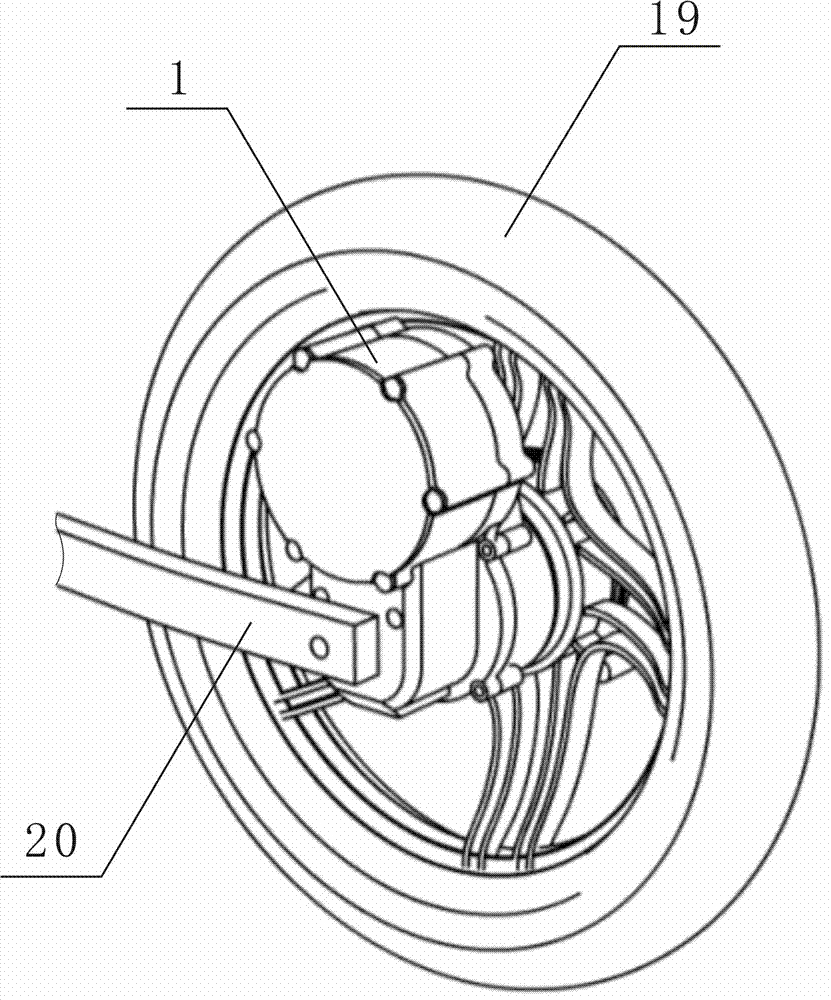

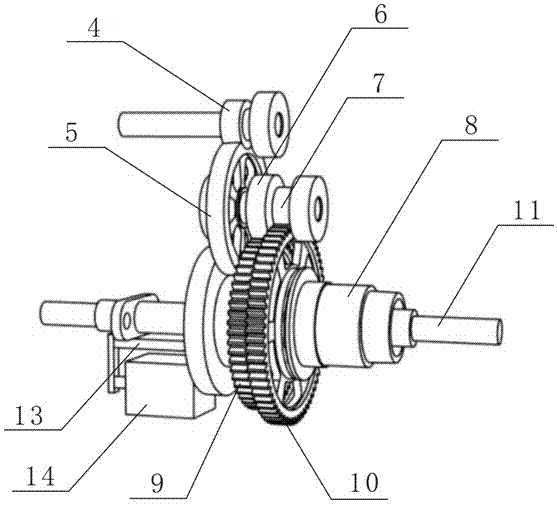

[0034] Example: see Figure 1 to Figure 6 , a driving device for an electric motorcycle, comprising a casing, a motor 1 and a speed change mechanism, the casing includes a vertically arranged mounting plate 2 and a gearbox 3 installed on the lower part of one side of the mounting plate 2, the speed change mechanism is installed In the gearbox 3; the motor 1 is installed on the upper part of the other side of the mounting plate 2 and is detachably connected with the mounting plate 2, and its output shaft passes through the mounting plate 2. During specific production, the mounting plate 2 can be The structure of the upper part is made to be consistent with the end cover of the motor 1, so that when installing the motor 1, the end cover at the output shaft end of the motor 1 can be removed, and the upper part of the mounting plate 2 can be directly used as the end cover of the motor 1, which can be better reduced The volume of the whole driving device is reduced, and it is more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com