Centring device

A technology of centering device and centering control system, which is applied in the field of centering device for metal strips, can solve the problems of strip edge damage, unreasonable process layout, insignificant deviation correction effect, etc., and achieves a large horizontal horizontal force component. , the correction effect is obvious, the effect of large correction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

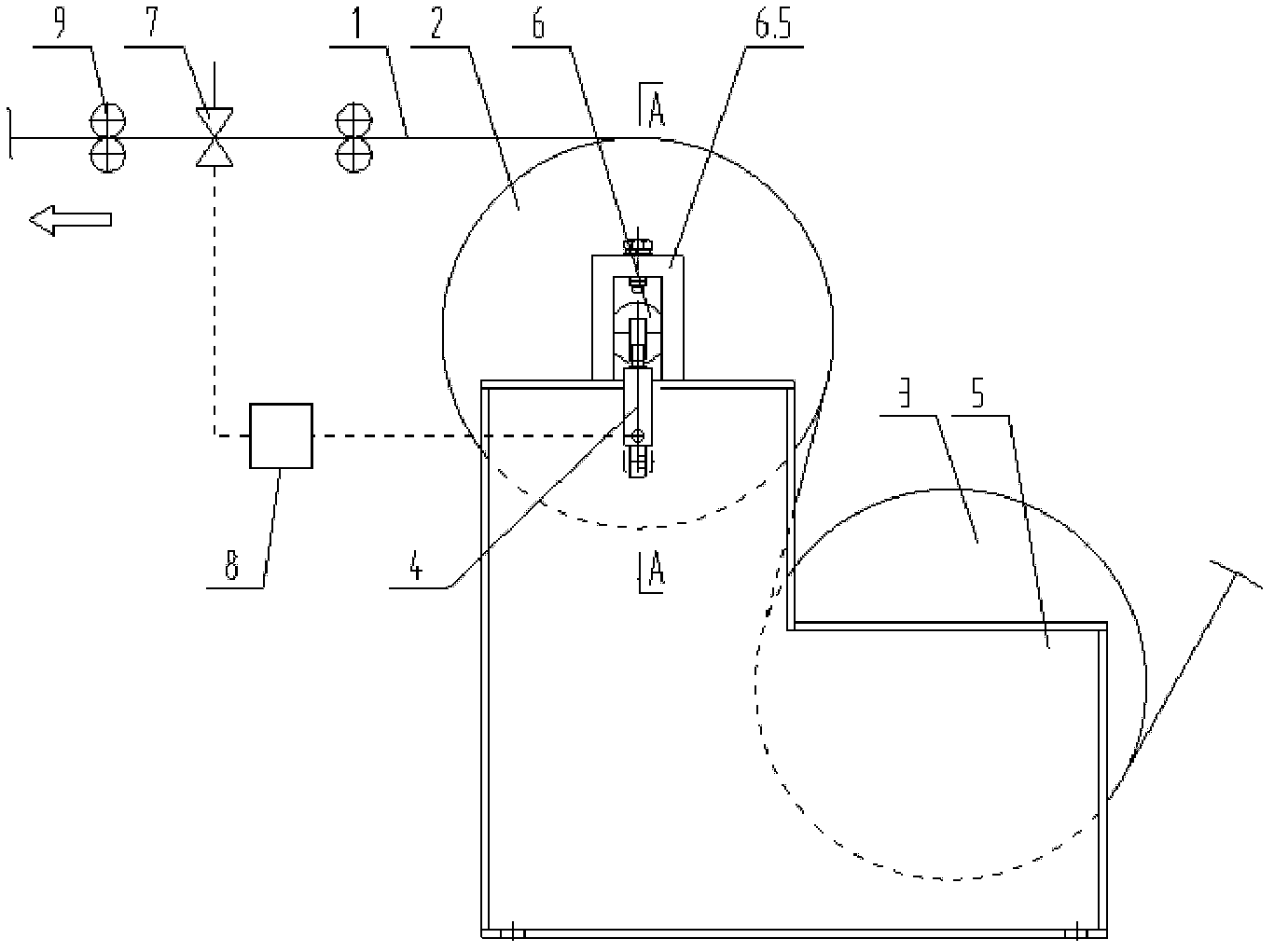

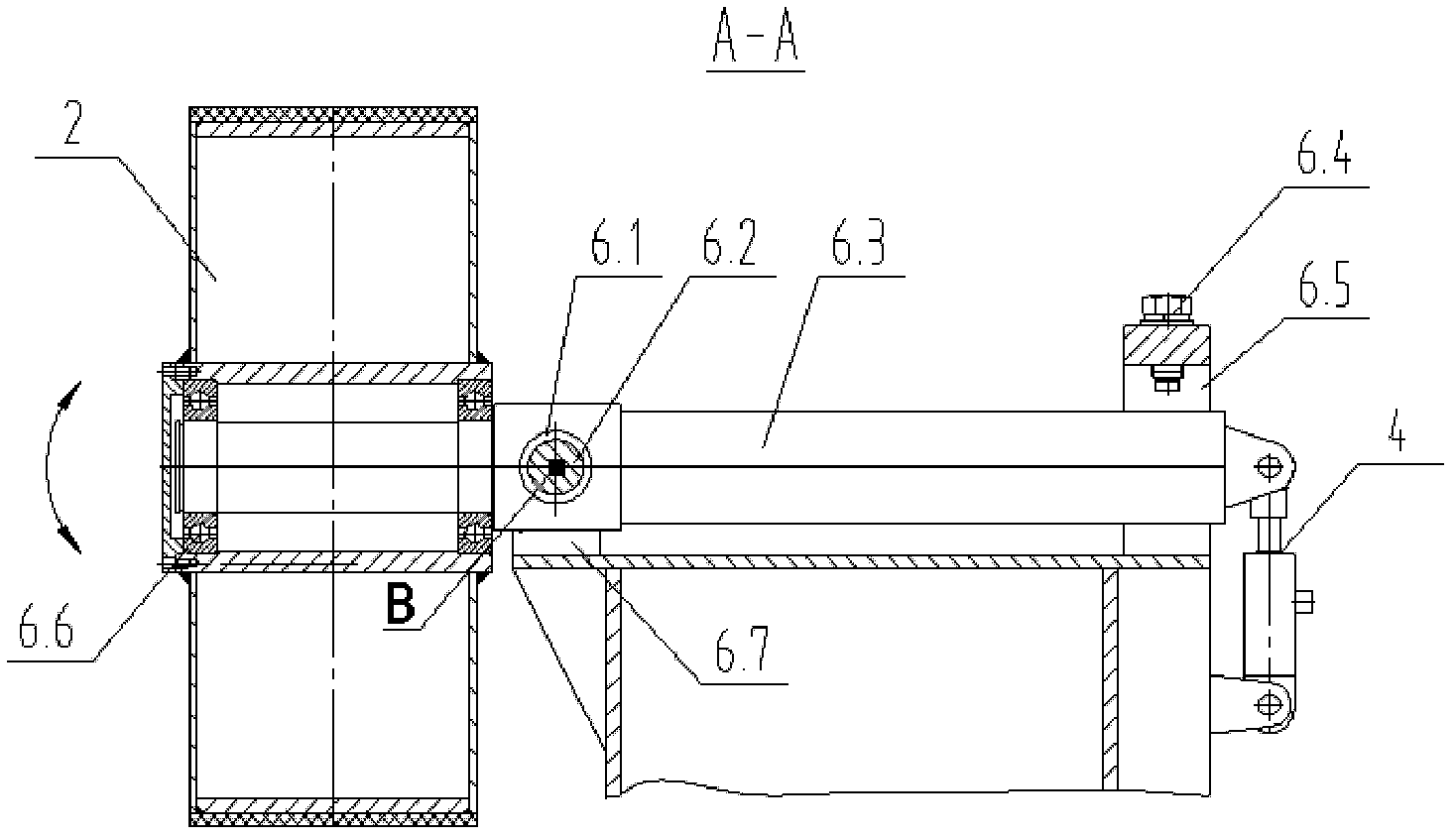

[0016] like Figures 1 to 2 As shown, the device includes a metal strip 1, a correction roller 2, a fixed roller 3, a hydraulic cylinder 4, a machine base 5, a swing shaft device 6, a position sensor 7, a centering control system 8 and a redirecting roller 9. Described swing shaft device 6 is made up of rolling bearing 6.1, fixed shaft 6.2, swing shaft 6.3, adjusting screw 6.4, guide rail device 6.5, rolling bearing 6.6, fixed shaft support 6.7. The deviation-correcting roller 2 and the fixed roller are arranged with upper and lower cantilevers, the deviation-correcting roller 2 is on the top, and the fixed roller 3 is on the bottom. The strip material is wound in an S shape on the deviation-correcting roller and the fixed roller respectively to form a certain package with the roller surface. Angle, the correction roller is installed on the rolling bearing 6.6 of the pendulum shaft 6.3, one end of the pendulum shaft 6.3 cantilevered and can only swing up and down along the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com