Crane as well as operation safety control system and method thereof

A safety control and crane technology, applied to cranes and other directions, can solve problems such as poor reliability, immediate shutdown in case of emergency, engine ECU unable to receive flameout signal, etc., to achieve the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

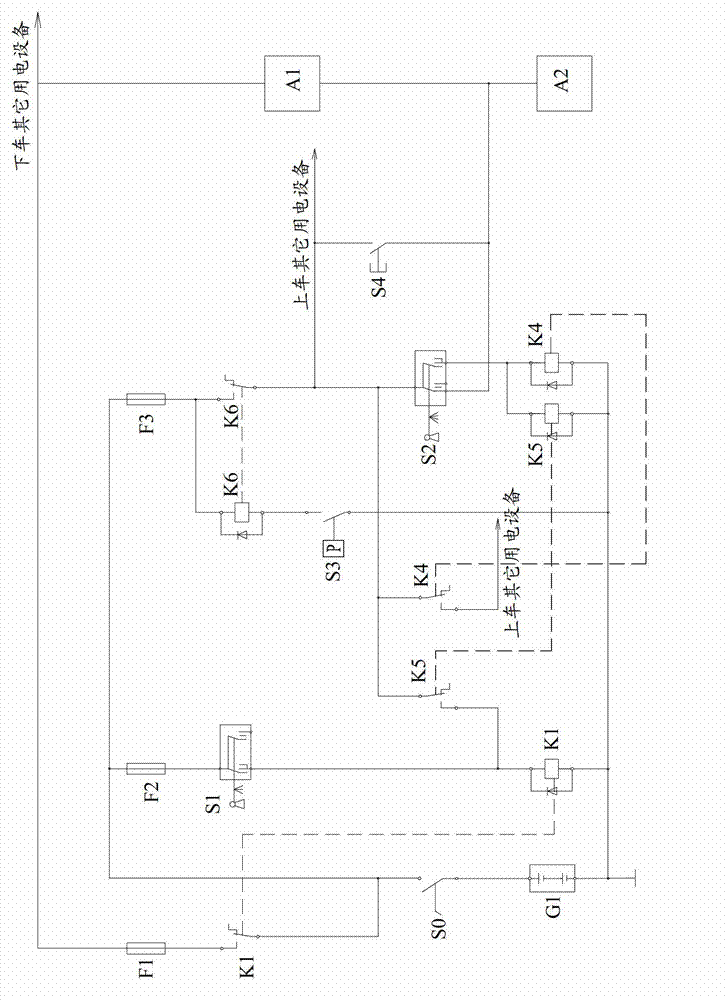

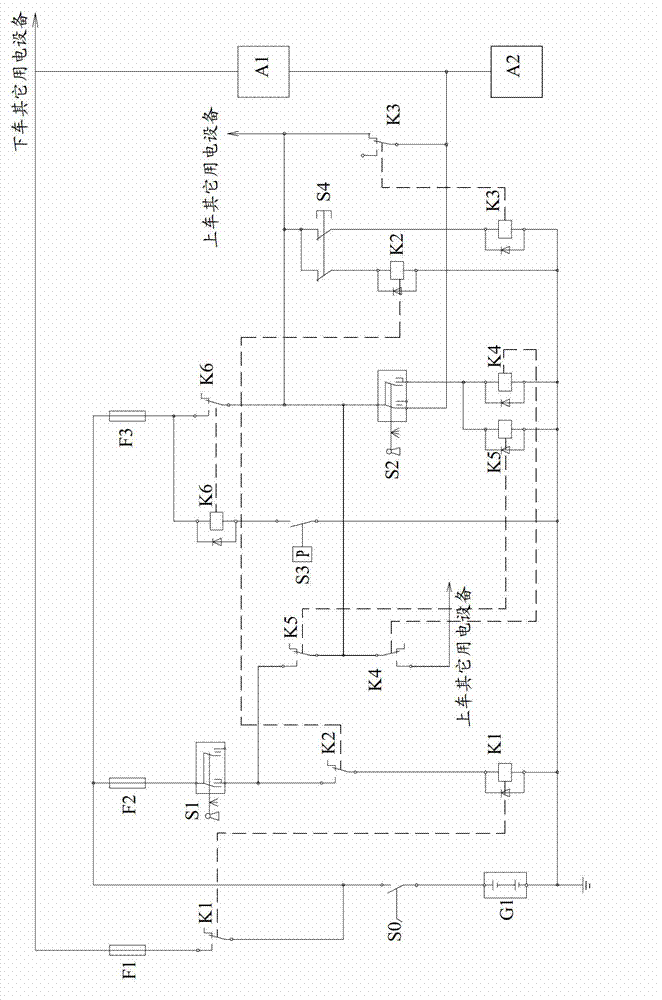

[0038] The core of the present invention is to provide a crane operation safety control system. When an unexpected emergency occurs during the boarding operation, the operator can cut off the power supply for the engine electronic control unit ECU through the emergency stop switch arranged in the boarding cab. The power supply line makes the engine ECU stop working, and the engine is turned off, so as to realize the operation safety control in a timely and effective manner.

[0039] Specifically, the operation safety control system of the crane mainly includes a power supply, an alighting control unit, and an onboard control unit; the power supply is connected to the power input end of the engine ECU through the first power supply line, and is connected to the engine ECU's flameout signal through the second power supply line. The input terminal is connected to the boarding controller; the getting off control unit connects or cuts off the first power supply line according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com