Resin asphalt concrete paving structure capable of being constructed at normal temperature, and paving method thereof

A resin asphalt and concrete technology, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of changing the high temperature and heavy load resistance of asphalt mixtures, weak anti-rutting ability, and increased construction temperature, and achieves obvious results. The effect of anti-corrosion and waterproof ability, guaranteeing the strength of the road surface, and obvious resistance to high temperature in summer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

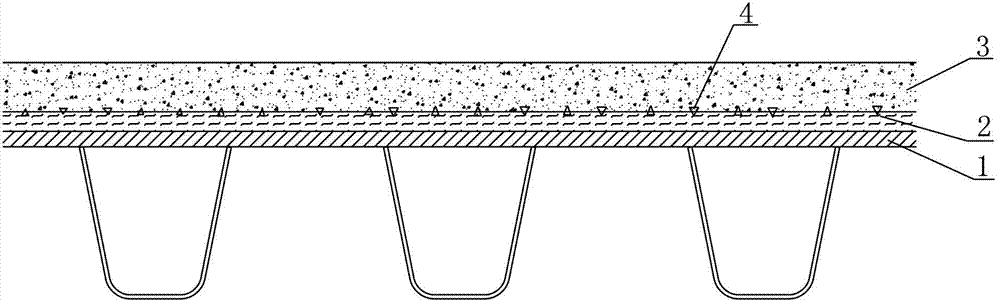

[0023] The present invention is a resin asphalt concrete pavement structure that can be constructed at room temperature. The pavement structure includes a resin asphalt waterproof and anti-slip interface layer 2 coated on a bridge deck steel plate 1 and a resin asphalt waterproof and anti-slip interface layer 2 laid on the resin asphalt interface layer 2. Cold-mixed resin asphalt concrete layer 3, according to the construction sequence, the pavement composite structure is divided into two layers:

[0024] The first layer: resin asphalt waterproof and anti-skid interface layer 2

[0025] Close the traffic on the maintenance lane, dig out the damaged original bridge deck pavement, and re-shot blast and derust the bridge deck steel plate to meet the standards of surface cleanliness Sa2.5 and roughness 60-100 μm; then immediately scrape on the surface Apply a layer of mixed resin asphalt, the amount of scraping is generally 1.0-1.2kg / m 2 , and then evenly spread a layer of small ...

Embodiment 2

[0036]The main bridge span of a newly built cable-stayed bridge in Zhejiang is 680 meters. It adopts a steel box girder structure. The thickness of the steel box girder roof plate is 14mm. The bridge is an important channel connecting the port. It is estimated that there are more than 20,000 heavy container vehicles per day. The area where the bridge is located is hot and rainy, and the highest temperature in summer can reach 41°C. The design unit decided to adopt the resin asphalt concrete (ER) of the present invention as the steel bridge deck pavement structure after scheme comparison and selection. The paving design thickness is 60mm, and the specific design scheme is as follows:

[0037] 1. The surface cleanliness of steel plate 1 on the bridge deck reaches Sa.2.5 level after shot blasting and derusting, and the roughness reaches 60-100 μm, and then scrape and coat resin asphalt at 1.0-1.2kg / m 2 , spread 3-5mm particle size of small gravel 4 is 4kg / m 2 After curing for 3...

Embodiment 3

[0042] Jiangsu XX Bridge is a steel box girder suspension bridge with a main span of 1590 meters. The original bridge deck pavement is a 5.5cm thick thermosetting epoxy asphalt concrete double-layer pavement structure imported from abroad. After 5 years of operation, many cracks and potholes appeared in the original steel bridge deck pavement, and surface water entered the steel plate at the bottom of the pavement layer through the cracks, causing corrosion of the steel plate on the bridge deck, and the pavement layer was more damaged under the action of water. serious. Although ordinary modified asphalt concrete and epoxy concrete were used to repair the damaged parts many times, the disease of bridge deck pavement could not be eliminated. In 2011, it was decided to use resin asphalt concrete ER pavement structure to repair the heavy-duty lane with severe damage to the original bridge deck.

[0043] The specific implementation steps are:

[0044] 1. Close the traffic on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com