H-shaped supporting pile made of prefabricated reinforced concrete

A technology of I-shaped piles and I-shaped piles, which is applied in the direction of sheet pile walls, foundation structure engineering, excavation, etc., can solve the problem of low extrusion of bored piles or immersed pipe piles, poor mechanical properties of soil pressure, and unfavorable saving of building materials resources and other issues, to achieve significant economic and technological achievements, shorten construction time, and save building material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

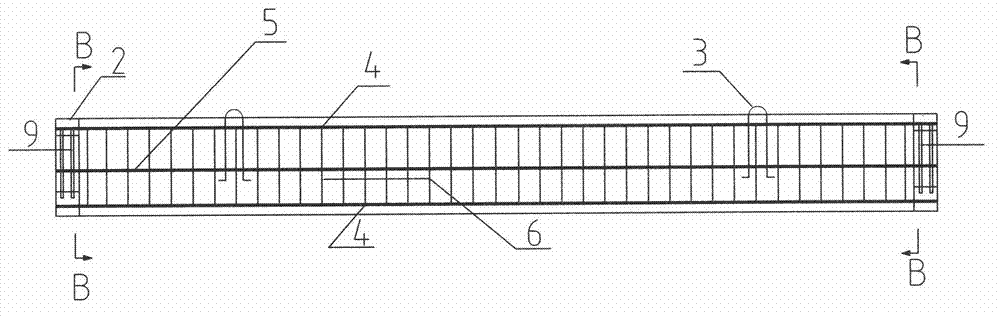

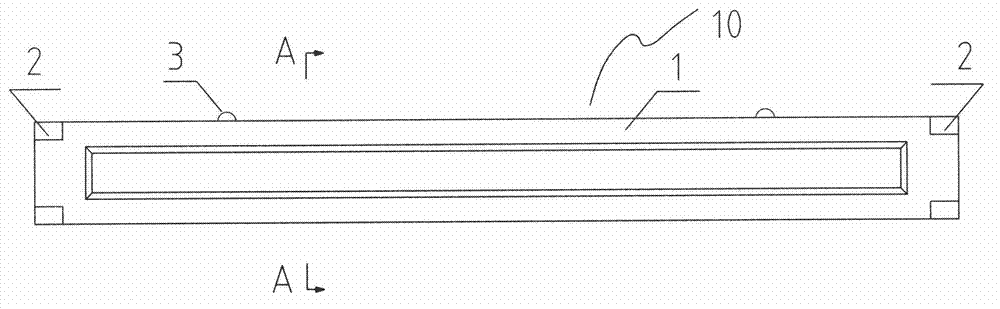

[0031] Figure 1 to Figure 13 An embodiment of the present invention is shown, which includes a standard pile section 10;

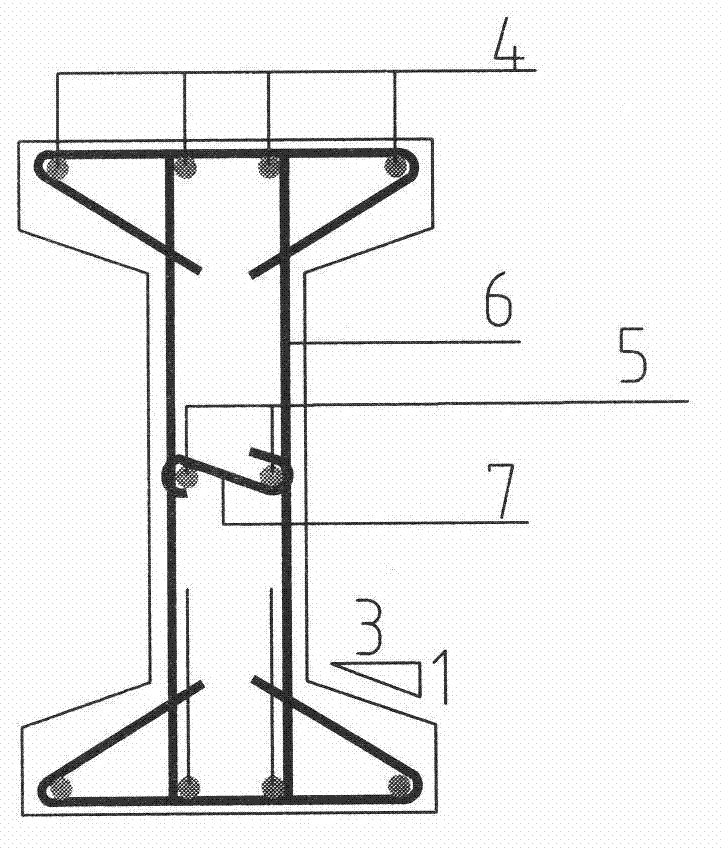

[0032] The standard pile section has an I-shaped cross section and an I-shaped hoop 6 composed of a steel skeleton, and an I-shaped pile section profile of reinforced concrete;

[0033] The I-shaped stirrup 6 is composed of two vertical stirrups 62 parallel to each other, an upper and lower triangular frame stirrup 61 which is connected to the upper and lower ends of the vertical stirrup and arranged symmetrically, and connected to the middle part between the two vertical stirrups. The connected "S" shaped stirrups 7, a plurality of main bars 4 longitudinally arranged along the bottom edge of the triangular frame bars, and two longitudinal internal steel bars 5 symmetrically arranged and longitudinally connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com