Method for preparing biomass compound liquid organic fertilizer by utilizing agricultural wastes

A technology of agricultural waste and biomass, applied in organic fertilizers, agriculture, inorganic fertilizers, etc., can solve the problems of limited application of soil environment and high cost of raw materials, and achieve obvious effects, good air permeability, and strong drought resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0048] Example 1:

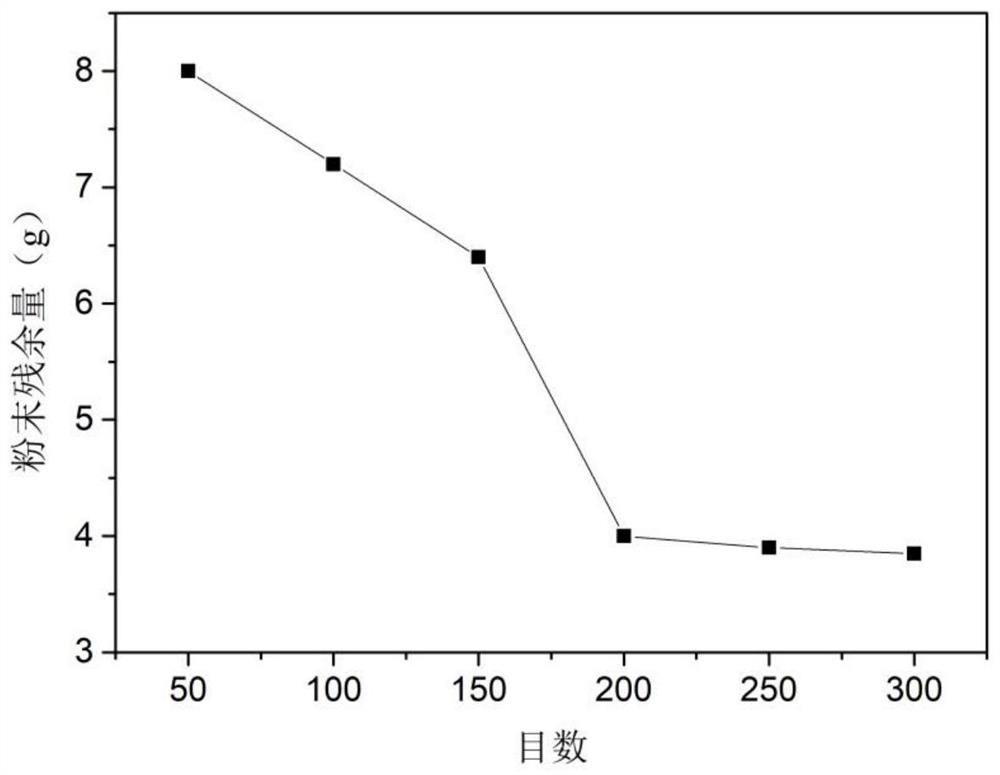

[0049] (1) The cotton stalks were crushed through 50,100,150,200,250,300 mesh sieve, referred to as sequence No. 1, No. 2, No. 3, No. 4, No. 5, No. 6, taken after sieving 1 to 6 above cotton stalk powder 8.0g were placed in 500mL six hydrothermal reaction vessel, and then take six 500mL beakers, each beaker was added 320g of distilled water, 16 mL of hydrogen peroxide, 32 mL of saturated ammonium acetate solution, 11 mL phosphoric acid, a substance beaker were stirred and uniformly dissolved into 1 to 6 hydrothermal reaction vessel in which the powder mixed with cotton stalk uniform, tightly cover placed in a reaction vessel in the hydrothermal blast oven 200 ℃ 2h, after cooling to room temperature the reaction vessel removed, the kettle contents was suction filtered to collect the filtrate and filter residue. The filter cake in an oven at 60 deg.] C in 12 hours after drying weighed mass. The results show that the 200 mesh sieve No. 4 After the resulting powder...

Example Embodiment

[0050] Example 2:

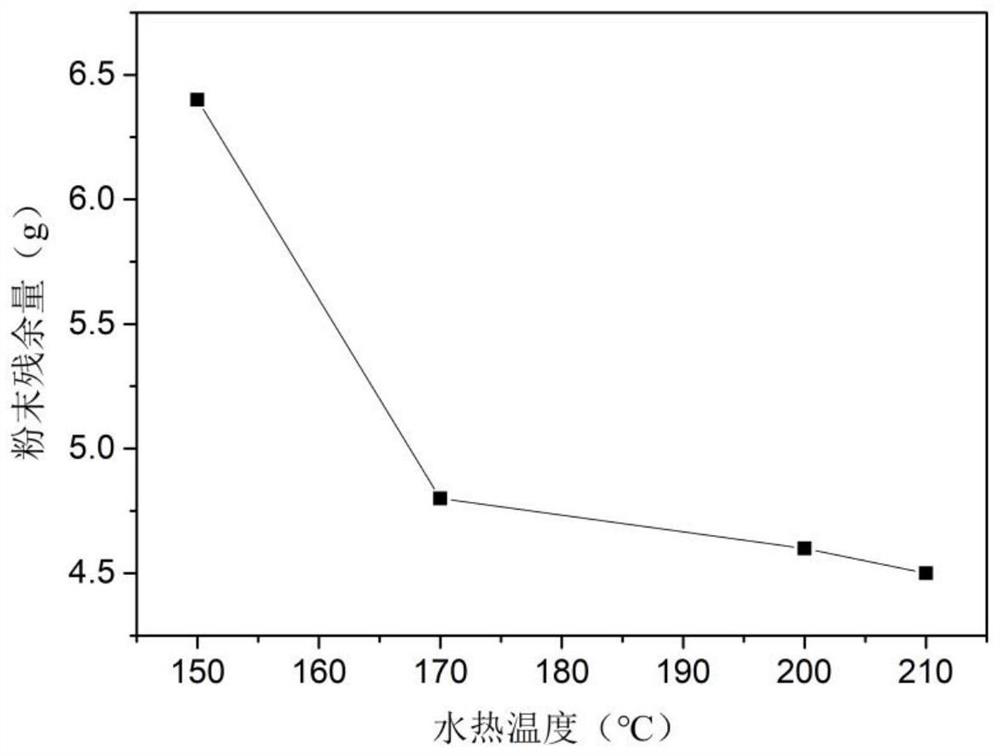

[0051] 4 parts of pulverized and weighed 200-mesh sieve cotton stalk powder 8.0g were placed in a hydrothermal reaction vessel 4 in 500mL then 500mL beaker take 4 and 320g of distilled water were added to each beaker, 16 mL of hydrogen peroxide , 32 mL of saturated ammonium acetate solution, 11 mL phosphoric acid, beaker substances were uniformly dissolved with stirring into a hydrothermal reaction vessel 4 with cotton stalk powder mixed therein, tightly blast oven lid was placed in water for thermal reaction, the temperature of 1 to 4 hydrothermal reaction kettle were 150 ℃, 170 ℃, 200 ℃ and 210 deg.] C, hydrothermal reaction times were 2h, the reaction was complete after cooling to room temperature, remove the reactor, the reaction material in the autoclave by suction filtration, and the filtrate residue were collected, the filter cake in an oven at 60 deg.] C the mass weighed after drying for 12 hours. The results show that, the hydrothermal reaction tempera...

Example Embodiment

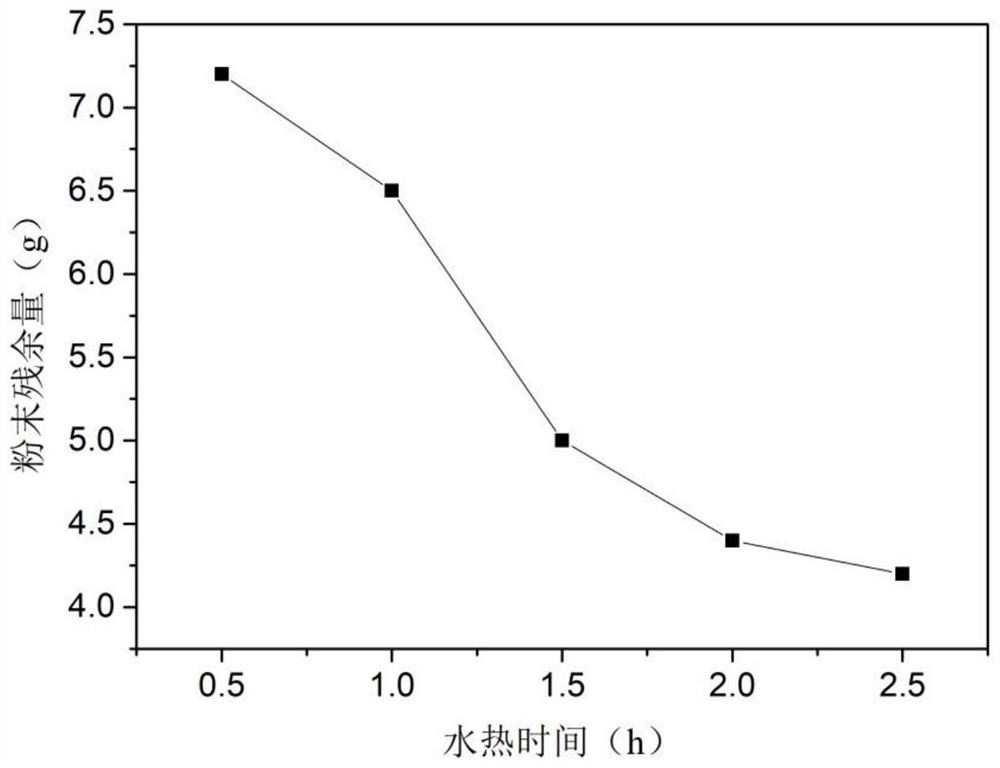

[0052] Example 3

[0053] 6 parts of pulverized and weighed 200-mesh sieve cotton stalk powder 8.0g were placed in 500mL 6 hydrothermal reaction vessel, followed by the six non 500mL beakers, each beaker was added 220g, respectively, 240g, 260g, 280g, 300g, 320g distilled water, and hydrogen peroxide were each added to 16mL beaker, 32 mL ammonium acetate solution, 11 mL phosphoric acid, the beaker were stirred for uniformly dissolved into 6 hydrothermal reaction vessel with which the cotton stalk powder mixed, placed tightly kettle lid 200 ℃ hydrothermal blast oven for 2h, the reaction was complete after cooling to room temperature, remove the reactor, the reaction mass in the autoclave suction filtration, the filtrate was collected and the filter cake, the filter cake 60 deg.] C in an oven dried 12 hours after the weighed mass. The results show that, the hydrothermal reaction in an amount of 260g distilled water, the resulting residue when small suction amount described large amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com