Fault prevention and control device for local ventilation system on driving face of coal mine

A technology for excavating working face and local ventilation, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc. The effect of preventing gas accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

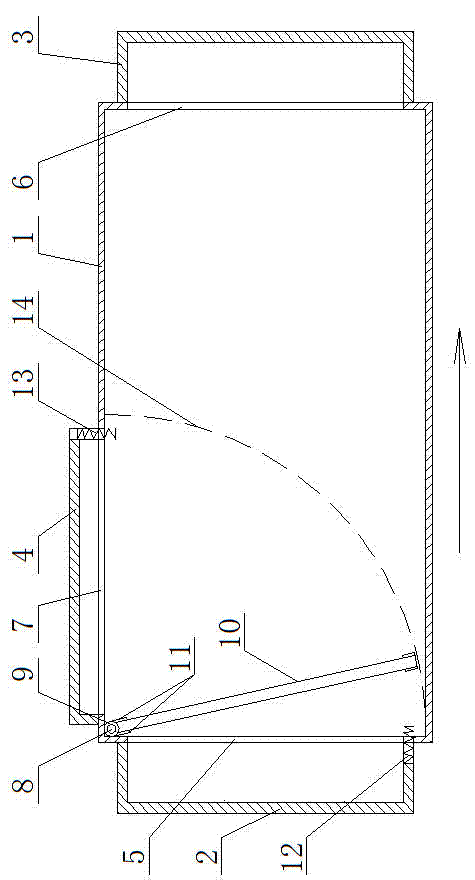

[0013] like figure 1 The shown fault prevention and control device for the local ventilation system of the coal mine excavation face includes a prevention and control pipeline 1 with a fan outlet 5 and an air duct inlet 6 on both ends, and a full negative pressure air outlet 7 on the side wall. There are fan connectors 2 at 5 air outlets, fan connectors 3 at 6 air inlets, and full negative pressure air flow connectors 4 at 7 full negative pressure air outlets. When in use, the prevention and control pipe 1 passes through The fan connector 2 is connected with the local ventilator, is connected with the fan cylinder through the fan connector 3 , and communicates with the downhole full negative pressure air flow through the full negative pressure air flow connector 4 . In the inside of the prevention and control pipeline 1, a rotating shaft 8 is movably arranged through a shaft sleeve 9, and a bidirectional wind deflector 10 is connected to the rotating shaft 8, and the bidirecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com