Automatic total moisture tester for coal sample

A technology of full moisture and tester, which is applied in the direction of instruments, analytical materials, and weighing by removing certain components, can solve the problems of slow speed, low work efficiency, and long time, and achieve high efficiency and solve technical bottlenecks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

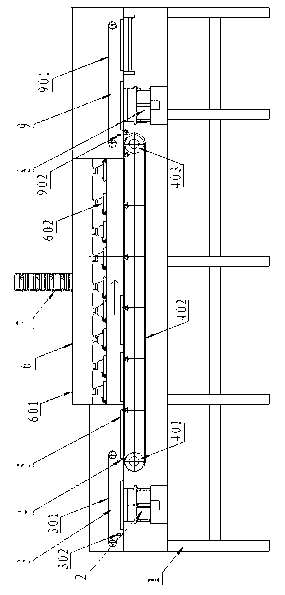

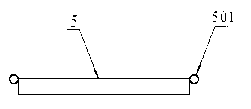

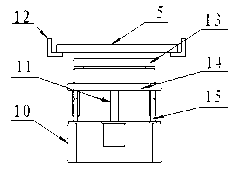

[0013] see figure 1 , automatic full moisture tester for coal samples, comprising a frame 1 arranged horizontally, two ends of the frame are respectively provided with a sample weighing device 2 and a sample weighing device 8, and a drying device 6 is arranged in the middle, and a sample feeding, A sample feeding device 3 and a sample discharging device 9 are respectively provided above the sample weighing devices 2 and 8, and a coal sample transmission device connected with the sample feeding device 2 and the sample weighing device 8 is provided below the drying device 6. device 4. The coal sample transmission device 4 adopts a belt conveyor, including a driving wheel 401 driven by a motor, a driven wheel 403, and a conveyor belt 402 wound around the driving wheel 401 and the driven wheel 403; the sample feeding device 3 and the sample discharging device 9 also use a belt Conveyor, on their belts 301,901, is provided with shifting block 302,902 respectively, is used to stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com