Touch liquid crystal grating and 3D touch display device

A liquid crystal grating and touch control technology, which is applied in the field of 3D display, can solve the problems of reducing the light transmittance of liquid crystal gratings and increasing the manufacturing cost, and achieves the effects of reducing the number of electrode layers, improving the light transmittance and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

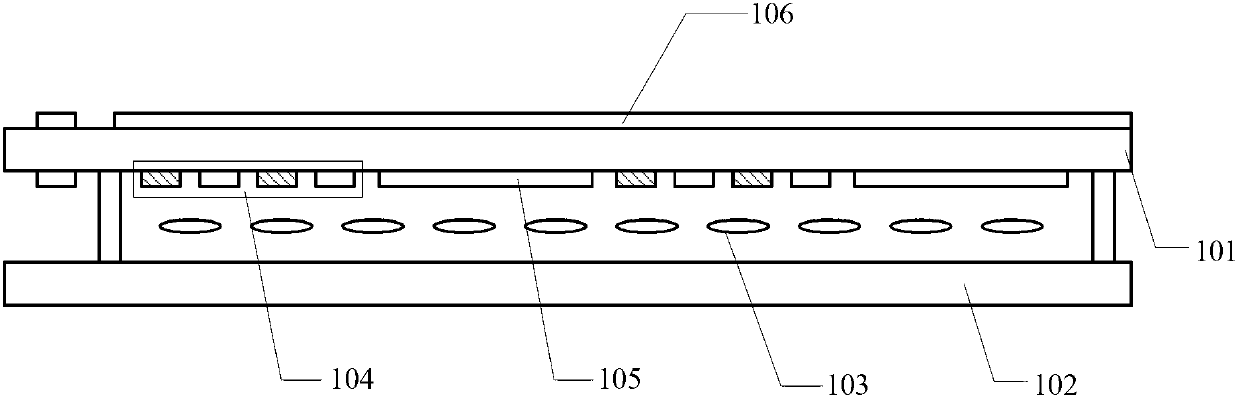

[0021] The specific implementation manners of the touch liquid crystal grating and the 3D touch display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

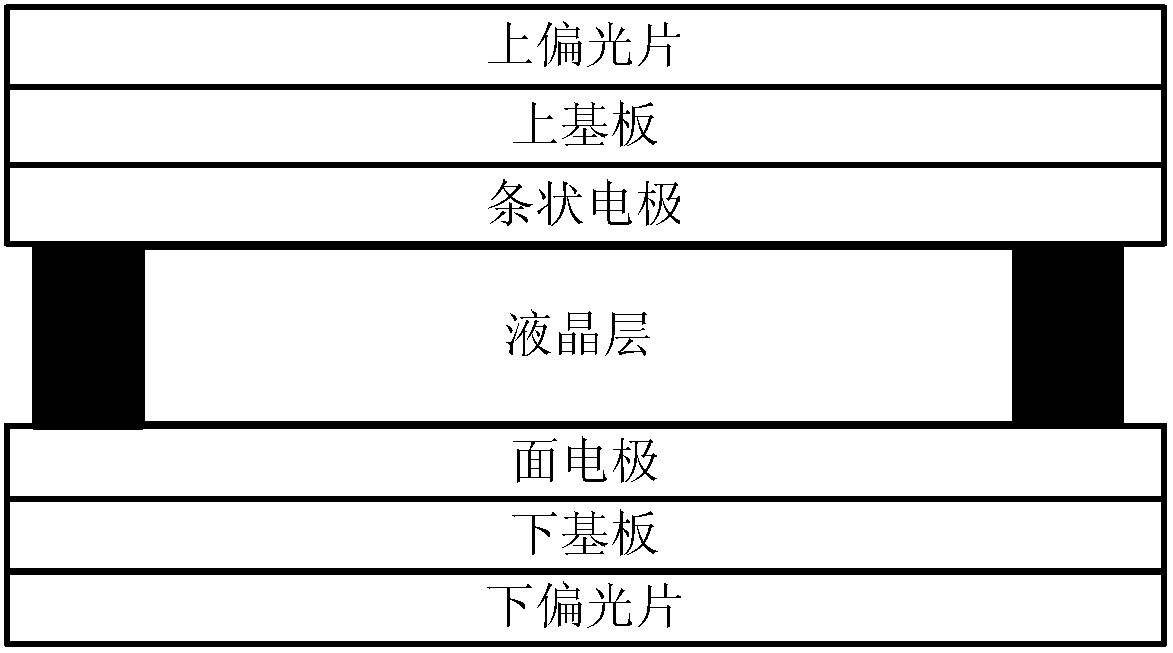

[0022] A kind of touch liquid crystal grating provided by the embodiment of the present invention, such as figure 2 As shown, it specifically includes: a first substrate 101, a second substrate 102, and a liquid crystal layer 103 filled between the first substrate 101 and the second substrate 102, and also includes:

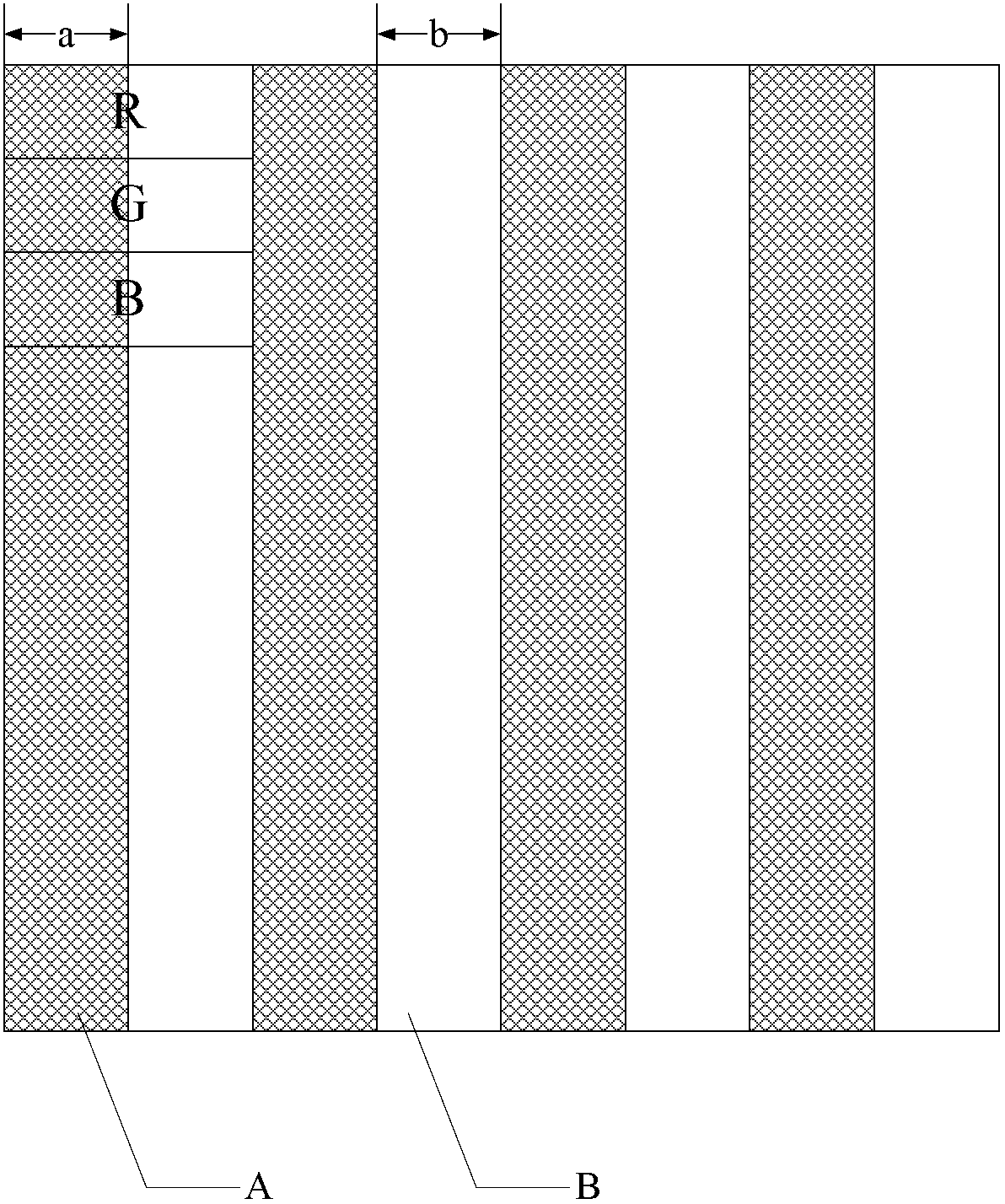

[0023] The grating electrodes 104 located on the side of the first substrate 101 facing the liquid crystal layer 103, each grating electrode 104 is located in the strip region A arranged at a set distance; when the grating electrode 104 is powered, the liquid crystal molecules corresponding to the strip region A generate Rotation, the liquid crystal molecules are aligned horizontally when no power is applied;

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com