Automatic pipe layout mechanism for receiving pipes of integrated circuits

An integrated circuit and material receiving pipe technology, applied in the field of automatic pipe discharging mechanism, can solve the problems of shutdown, low discharge accuracy, high labor intensity, etc., and achieve the effect of smooth process flow, avoiding equipment accidents, and improving pipe discharging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

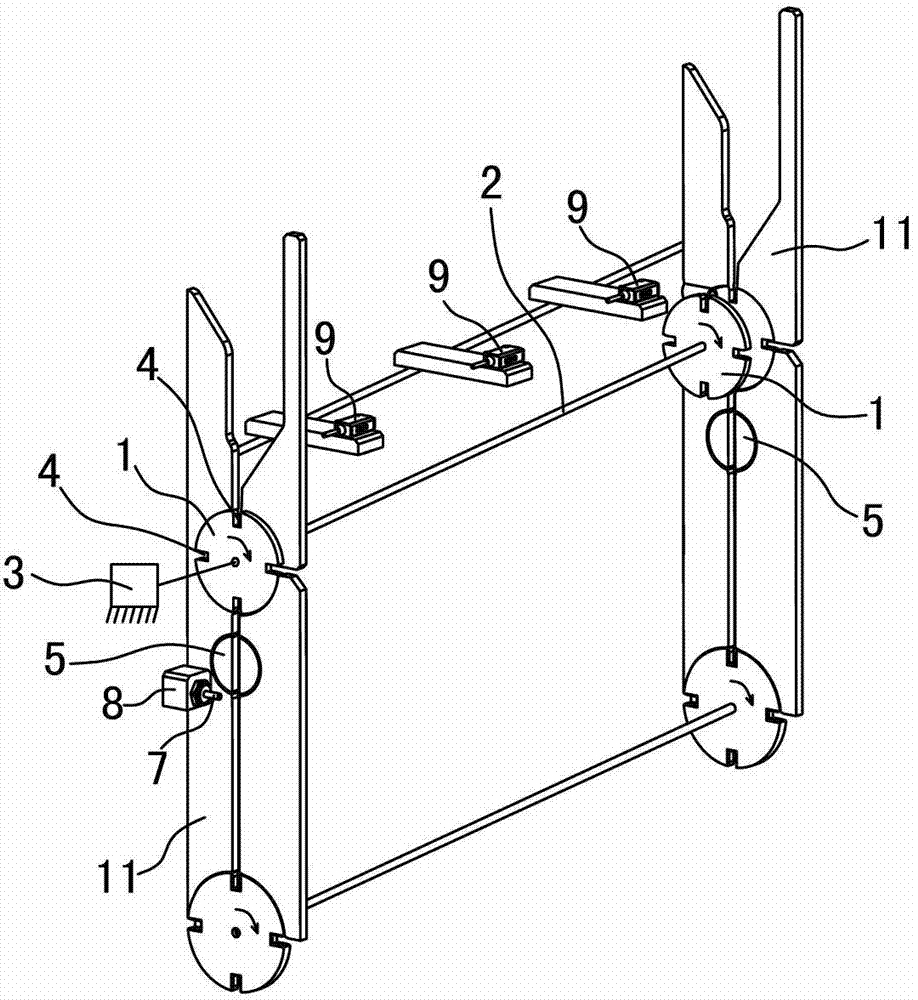

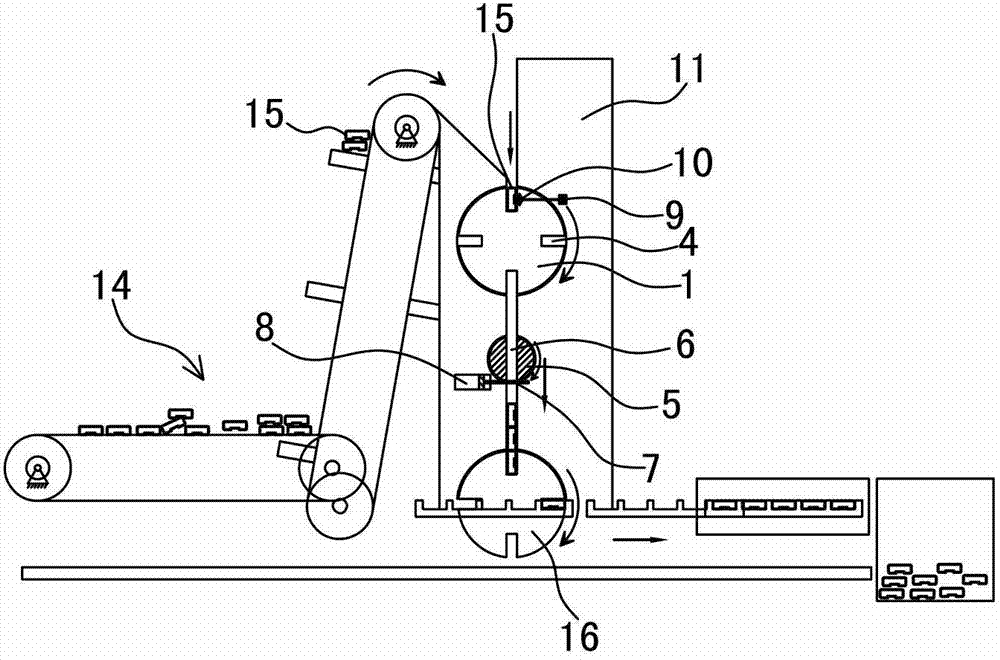

[0043] Embodiment: A kind of integrated circuit collecting tube automatic tube arrangement mechanism

[0044] See attached figure 1 ~ attached Figure 6 As shown, the automatic pipe arrangement mechanism is composed of a single pipe separation mechanism and a reversing mechanism, wherein:

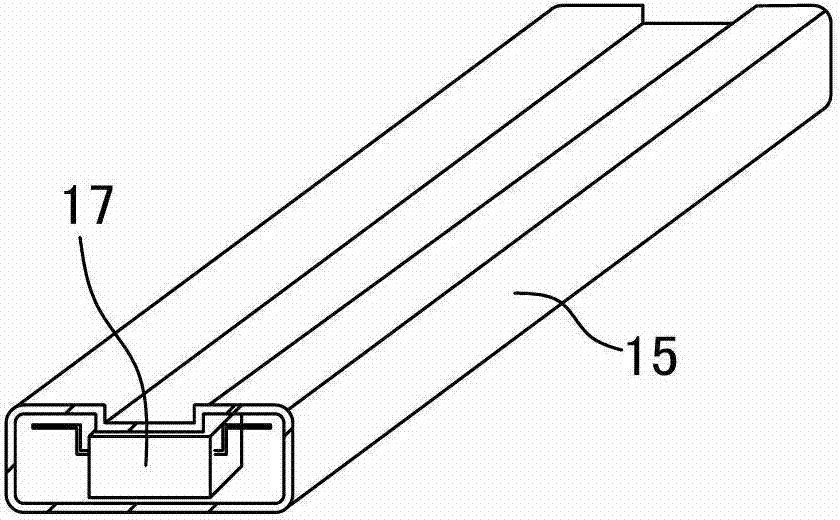

[0045] The single-tube separation mechanism is composed of two single-tube separation wheels 1 with the same structure, each single-tube separation wheel 1 is fixedly arranged on a rotating shaft 2, and the rotating shaft 2 is arranged horizontally and is transmitted with a first rotating drive mechanism 3 Connected, the first rotary drive mechanism 3 drives the rotating shaft 2 to rotate 90 degrees each time, and the outer peripheral surface of each single-tube separation wheel 1 is provided with four single-tube grooves 4, and the single-tube groove 4 on each single-tube separation wheel 1 The central line is parallel to the axial direction of the rotating shaft 2 , and at least one det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com