Preparation method of positive material for lithium-sulfur battery

A sulfur cathode material and cathode material technology, applied in the field of electrochemical cells, can solve problems such as environmental pollution, and achieve the effects of high conductivity, high yield and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

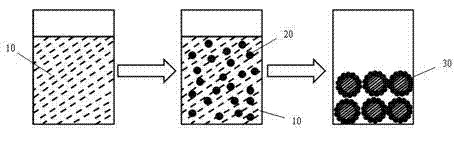

Method used

Image

Examples

Embodiment 1

[0031] Step 1, prepare sulfur-organic solution: mix 2 g elemental sulfur with 20 g carbon disulfide (CS 2 ) were mixed evenly to form a uniform 10wt% sulfur-carbon disulfide solution.

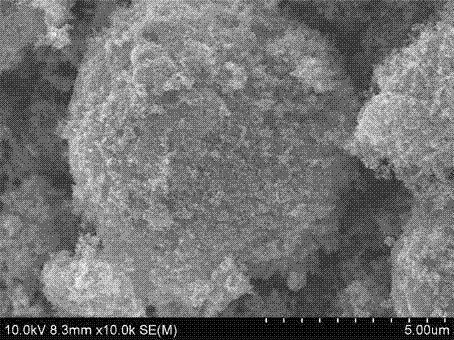

[0032] Step 2: Add 0.5 g of nitric acid-treated carbon black (XE-2) to 10 wt% sulfur-carbon disulfide solution, stir magnetically for 30 min, and naturally volatilize carbon disulfide at room temperature, and obtain sulfur / carbon composites after complete drying. The particle size is about 3-5 mm, such as figure 2 shown.

[0033] Sulfur / carbon composite material is used as the active material, mixed with conductive agent carbon black (SP) and binder polyvinylidene fluoride (PVDF) at a mass ratio of 8:1:1, and N-methyl-2-pyrrolidone (NMP ) as a solvent, the slurry was synthesized with a magnetic stirrer and evenly coated on the current collector Al foil, and then dried in a vacuum oven at 50 °C for 24 h, and set aside. Lithium metal sheet as negative electrode, sulfur / carbon composite materi...

Embodiment 2

[0036] Step 1, preparation of sulfur-organic solution: 1.2 g of elemental sulfur and 120 g of toluene were evenly mixed to form a uniform 1wt% sulfur-toluene solution.

[0037] Step 2: Add 0.5 g carbon black (XE-2) to 1 wt% sulfur-toluene solution, stir magnetically for 30 min, and naturally volatilize the toluene at room temperature, and obtain sulfur / carbon composites after complete drying.

[0038] The method for preparing the positive pole piece and the method for assembling the battery are the same as in Example 1.

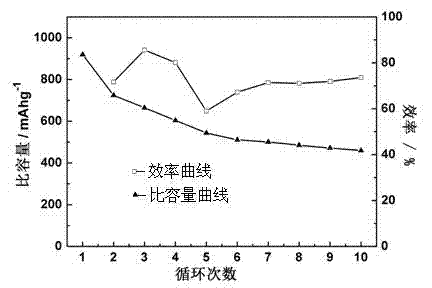

[0039] The battery was first charged and discharged at a current density of 50 mA / g, and the voltage range was 1.5-2.8 V. The initial discharge capacity was 928.9 mAh / g, and after 10 cycles, the discharge capacity was 604.2 mAh / g, the capacity retention rate was 65%, and the average efficiency was 72%.

Embodiment 3

[0041] Step 1, preparation of sulfur-organic solution: 2 g of elemental sulfur and 40 g of cyclohexane were evenly mixed to form a uniform 5wt% sulfur-cyclohexane solution.

[0042] Step 2: Add 0.2 g of nitric acid-treated carbon black (XE-2) to 5 wt% sulfur-cyclohexane solution, stir magnetically for 30 min, and naturally volatilize cyclohexane at room temperature, and obtain sulfur / carbon composites after complete drying.

[0043] The method for preparing the positive pole piece and the method for assembling the battery are the same as in Example 1.

[0044] The battery was first charged and discharged at a current density of 50 mA / g, and the voltage range was 1.5-2.8 V. The initial discharge capacity was 936.7 mAh / g, and after 10 cycles, the discharge capacity was 632.1 mAh / g, the capacity retention rate was 67%, and the average efficiency was 71%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com