Sheathing method for pure lead flat plate cell

A technology of flat battery and cladding board, which is applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. It can solve problems such as difficult operation, easy bending of tabs, and low efficiency, so as to ensure welding quality, Highly consistent, efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

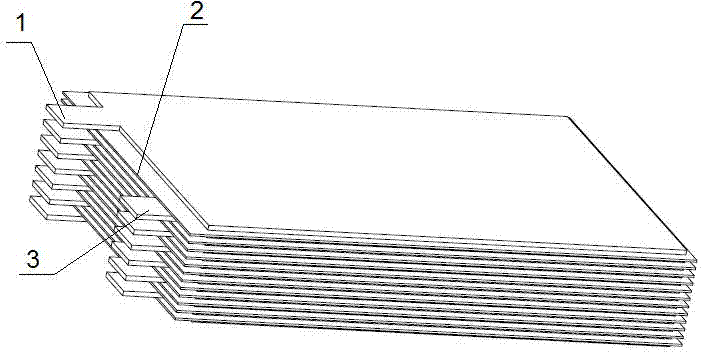

[0008] Such as figure 1 As shown, the following steps are used to wrap the plate: step 1, put the negative plate 1; step 2, put the AGM separator 2 on the top of the negative plate 1, there is a margin around the separator to prevent short circuit, especially there is enough margin at the bottom of the plate; Step 3, put the positive plate 3 on top of the AGM separator 2; Step 4, put the negative plate 1 again; Step 5, alternate the above steps to complete the ratio required by the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com