Novel three-phase photovoltaic grid-connected inverter system

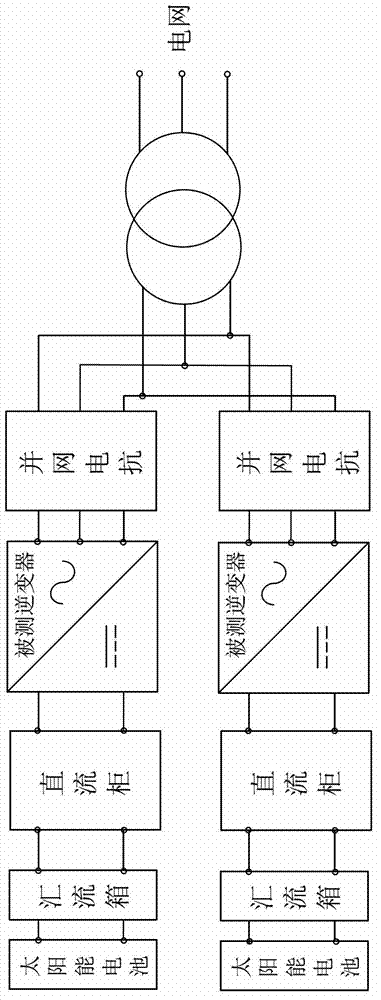

An inverter, three-phase technology, applied in the field of new three-phase photovoltaic grid-connected inverter system, can solve the problems of low power generation efficiency, low grid-connected voltage, unable to realize grid-connected photovoltaic array, etc. The effect of increasing the voltage on the grid-connected side, improving the utilization rate of light energy and the power generation efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

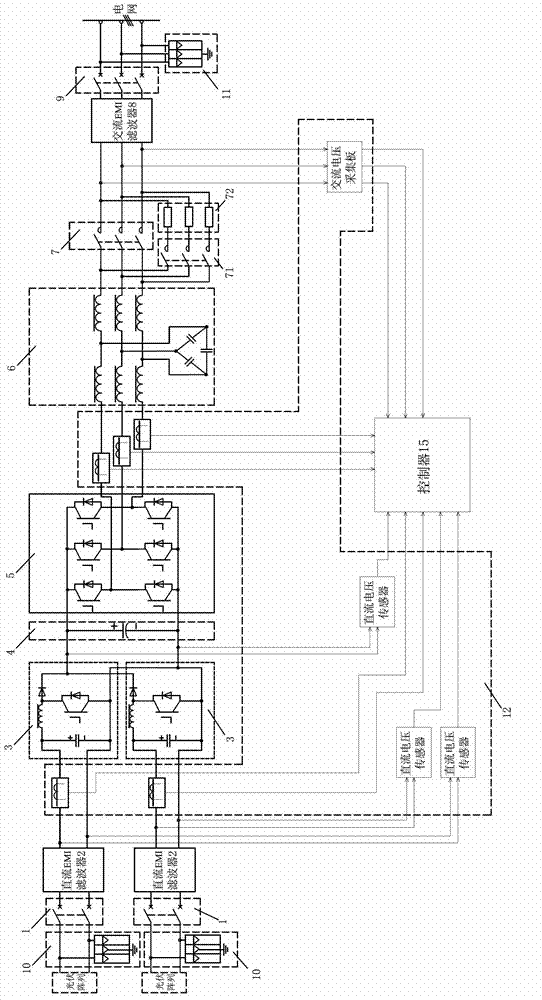

[0028] Example 1, such as figure 1 As shown, there are two photovoltaic arrays, and when the output DC voltage levels are 500V and 700V respectively, each photovoltaic array is boosted by a DC circuit breaker 1, a DC EMI filter 2, and a BOOST boost circuit 3. And the controller 15 carries out the maximum power tracking control of the BOOST booster circuit 3, boosts the voltage to 960V level, and then performs three-phase inverter grid-connected power generation through the three-phase full-bridge IGBT inverter circuit 5, and the grid-connected voltage can be increased To above 620V, through the above structure, two different photovoltaic arrays are connected to the grid together, which not only expands the maximum power point tracking range, but also improves the DC side voltage and inverter conversion efficiency.

Embodiment 2

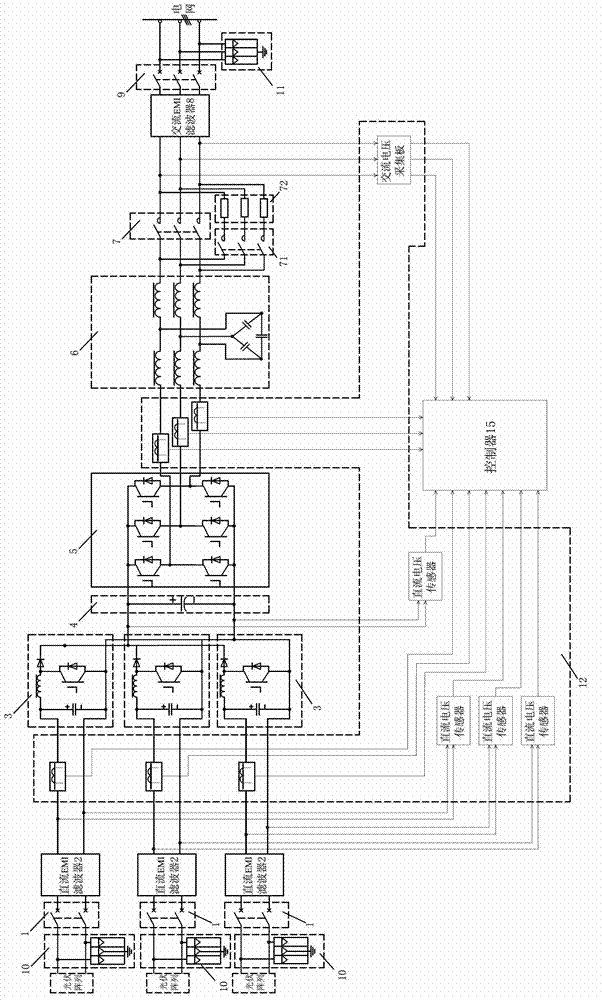

[0029] Example 2, such as figure 2 As shown, there are three photovoltaic arrays, and when the output DC voltage levels are 500V, 700V, and 900V, each photovoltaic array is boosted by a DC circuit breaker 1, a DC EMI filter 2, and a BOOST booster circuit 3. voltage, and the controller 15 performs maximum power tracking control of the BOOST booster circuit 3, boosts the DC side voltage to 960V level, and then performs three-phase inverter grid-connected power generation through the three-phase full-bridge IGBT inverter circuit 5, and The grid voltage can be increased to above 620V. Through the above structure, three different photovoltaic arrays can be connected to the grid together, which not only expands the maximum power point tracking range, but also improves the DC side voltage and inverter conversion efficiency.

[0030] The sinusoidal filter 6 described in the above two embodiments adopts an LCL sinusoidal filter to eliminate harmonics to obtain alternating current with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com