Sectionally coated spring plate and electric acoustic device using same

An electro-acoustic device and shrapnel technology are applied in the field of shrapnel and electro-acoustic devices using the shrapnel to achieve the effects of saving cost, improving sensitivity and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment and with reference to accompanying drawing.

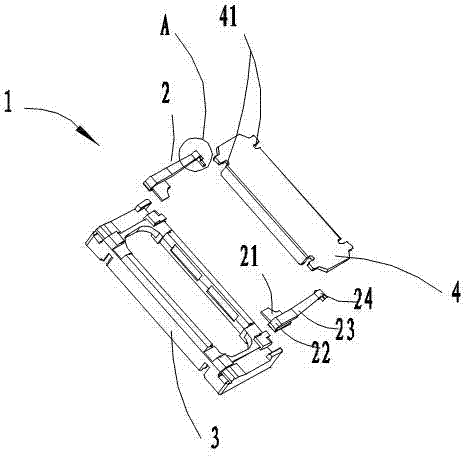

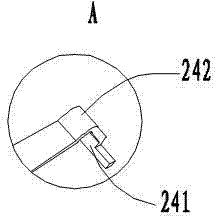

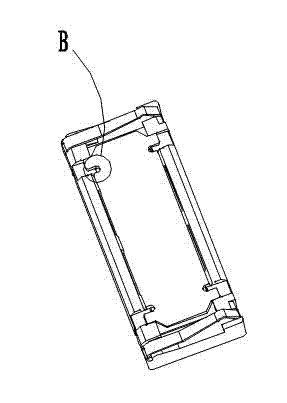

[0020] Such as figure 1 and figure 2 , the electroacoustic device 1 of the present invention includes a shrapnel 2 , a bracket 3 and a magnetic cup 4 . The shrapnel 2 includes a pad end 21, a bent portion 22 extends from the pad end 21, the bent portion 22 is connected to the shrapnel arm 23, and an arc-shaped end 24 extends from the shrapnel arm 23, and the arc-shaped end 24 can be connected to an external circuit. The surface material of the pad end 21, the bent portion 22, the spring arm 23 and the inner surface 241 of the arc end 24 is tin, the outer surface 242 of the arc end 24 is made of gold, and the lead-out wire (unmarked) of the voice coil passes through the point Welded on the pad end 11 by means of soldering. Four arc-shaped cutouts 41 are provided on the edge of the magnetic cup 4, the magnetic cup 4 is loaded into the brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com