Cutting method of dough

A cutting method and slitting technology, applied in the field of food processing, can solve the problems of poor surface effect, cross-section, broken noodles, uneven thickness of noodles, etc., and achieve the effect of high efficiency and good cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

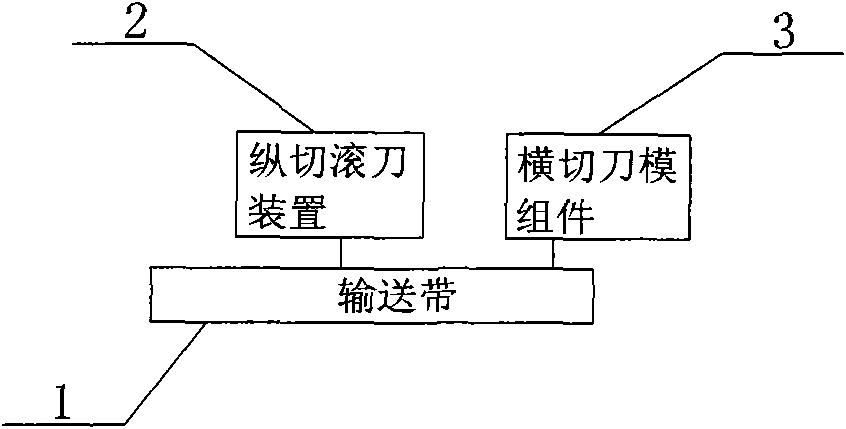

[0007] refer to figure 1 , the specific embodiment adopts the following technical scheme: it includes a conveyor belt 1, a slitting hob device 2 and a cross-cutting knife module assembly 3, and a slitting hob device 2 and a cross-cutting knife module are sequentially arranged above the conveyor belt 1 Part 3; its working project is: the conveyor belt 1 drives the noodle belt to move at the same speed, and after the slitting hob device 2, the hob divides the noodle belt into narrow noodle belts with the same width, and the narrow noodle belt continues to run with the conveyor belt. The proximity switch gives a signal, the conveyor belt stops, and the cross-cutting die assembly 3 moves to cut the narrow noodle strip into triangular noodle blanks of equal size.

[0008] This specific embodiment can cut the noodle strips into triangular noodle blanks of equal size, with good cutting effect and high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com