Inner bore grooving cutter

An inner hole groove and tool holder technology, which is applied in metal processing equipment, tangent devices, manufacturing tools, etc., can solve the problems of reducing tool service life, reducing tool thread processing efficiency, and uneven chip removal, and achieving smooth tool cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

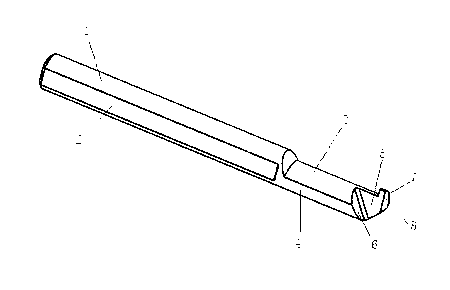

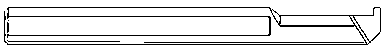

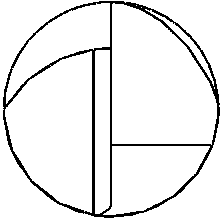

[0012] Example, by figure 1 , figure 2 , image 3 Shown:

[0013] The inner hole slotting cutter of this embodiment has an integrally formed structure, which has a cylindrical handle 1, and a holding plane 2 is milled out on the handle 1, so that the cutter can be more stably held on the tool holder; The front end is milled with an arc surface 3, which intersects with the extension surface 4 of the outer arc of the handle to form a transitional shank with a cross-sectional shape that is approximately oval (cat-eye-shaped), and the transitional shank is thinner than the shank , during processing, the tool rod goes deep into the hole, and the gap between it and the hole wall is relatively large, so that the cutting debris can be discharged smoothly; the front end of the transition tool rod is milled with a section plane 5 parallel to the axis of the tool bar, and the section plane It and the inclined section 6 of the transition tool bar form the chip removal groove of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com