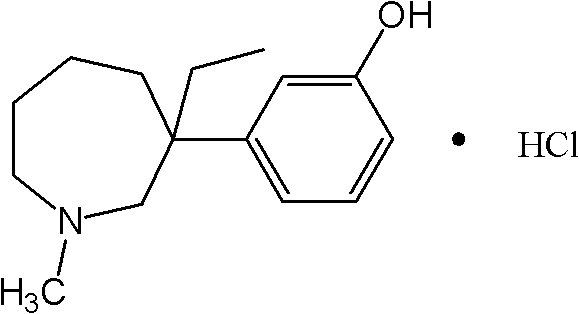

Preparation method for intermediate II during meptazinol hydrochloride synthesis process

A technology of the synthetic process of mebutamol hydrochloride, which is applied in the direction of organic chemistry, etc., to achieve the effects of high yield, shortened time, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

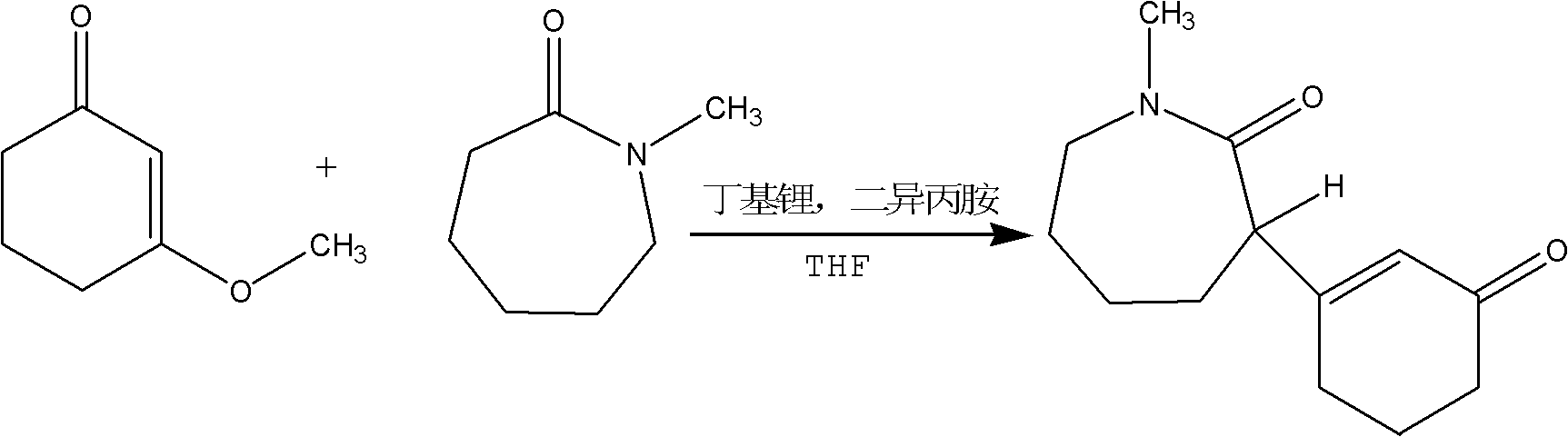

Method used

Image

Examples

Embodiment Construction

[0017] Below, in conjunction with embodiment the content of the present invention is described in detail.

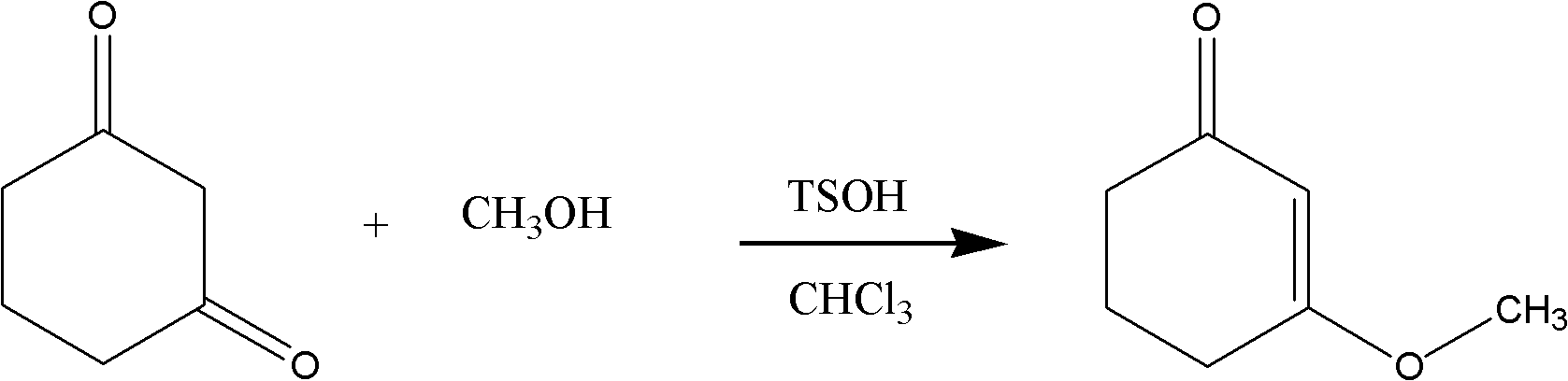

[0018] (1) Preparation of 3-methoxy-2-cyclohexenone (intermediate I)

[0019]

[0020] 1. Feeding ratio:

[0021] 1,3-cyclohexanedione FW=112.05 1800g 16mol

[0022] Methanol FW=32.03 4500g 140mol

[0023] Chloroform d=1.47 24000-28000ml

[0024] 2. Operation steps:

[0025] Add 1,3-cyclohexanedione, chloroform, methanol and 20g of p-toluenesulfonic acid into the reaction flask in sequence, heat up to boiling with stirring, and slowly distill out about 20000ml of distillate, which takes 5 to 7 hours. Remove from heat and cool to room temperature. Samples were taken by TLC to confirm that the reaction was normal and post-processed. Wash the residue with 10000ml of 10% sodium hydroxide for 3 times, combine the lye layers, and extract with 3000ml of distilled liquid. The organic layers were combined, washed with saturated brine 2000ml*2 until neutral, and dried ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com