Non-residual voltage monitoring device for gapless metal oxide lightning arresters and measurement method

A monitoring device and lightning arrester technology, which is applied in measuring devices, measuring electrical variables, measuring current/voltage, etc., can solve problems such as residual voltage, low detection accuracy, and complicated operating conditions, so as to speed up speed and accuracy, and apply Prospects and precise measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments of the present invention and accompanying drawings.

[0024] The invention relates to a non-residual voltage monitoring device and a measuring method for a gapless metal oxide lightning arrester.

[0025] Gapless metal oxide arrester without residual voltage monitoring device, the hardware part mainly includes:

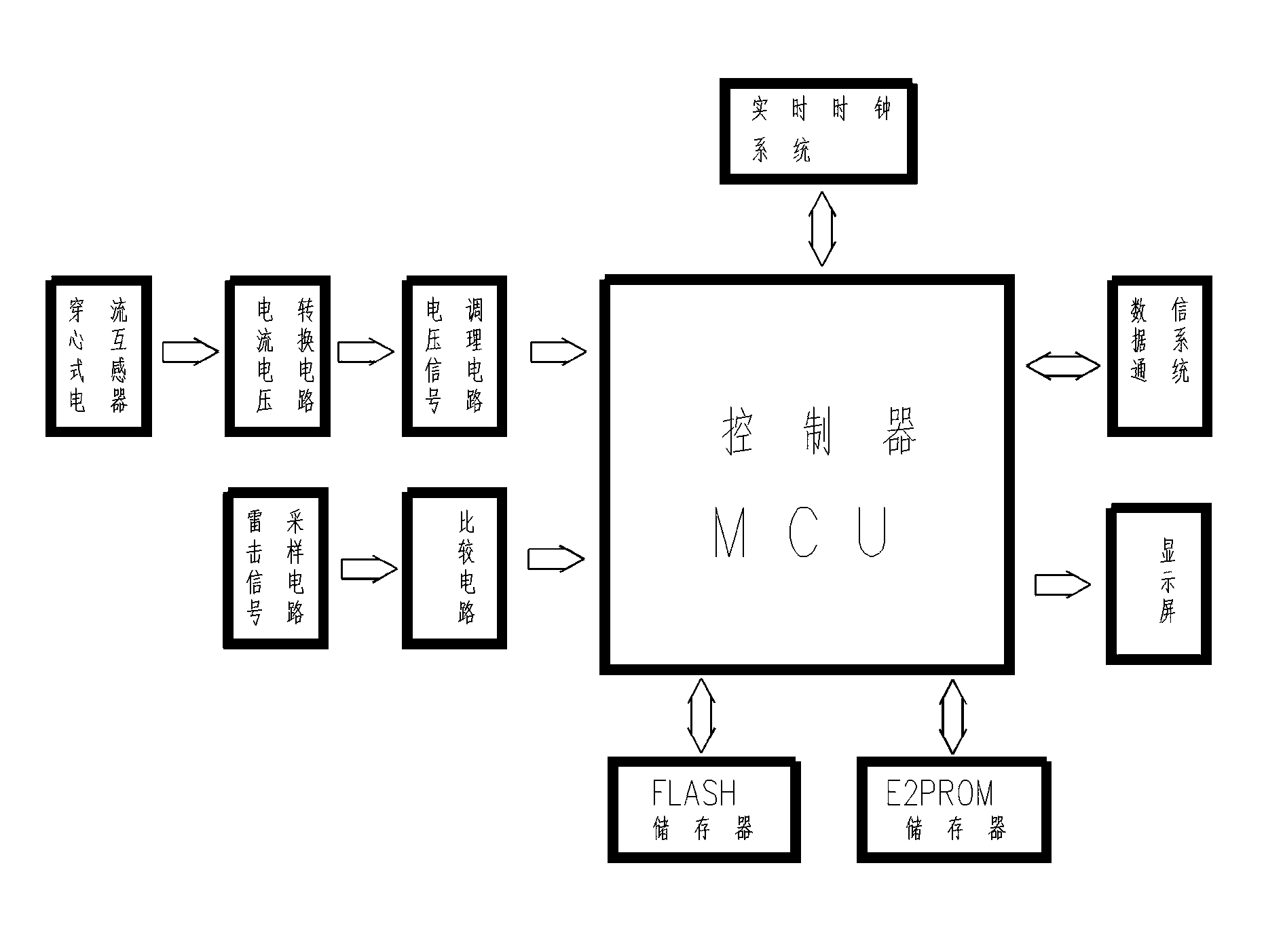

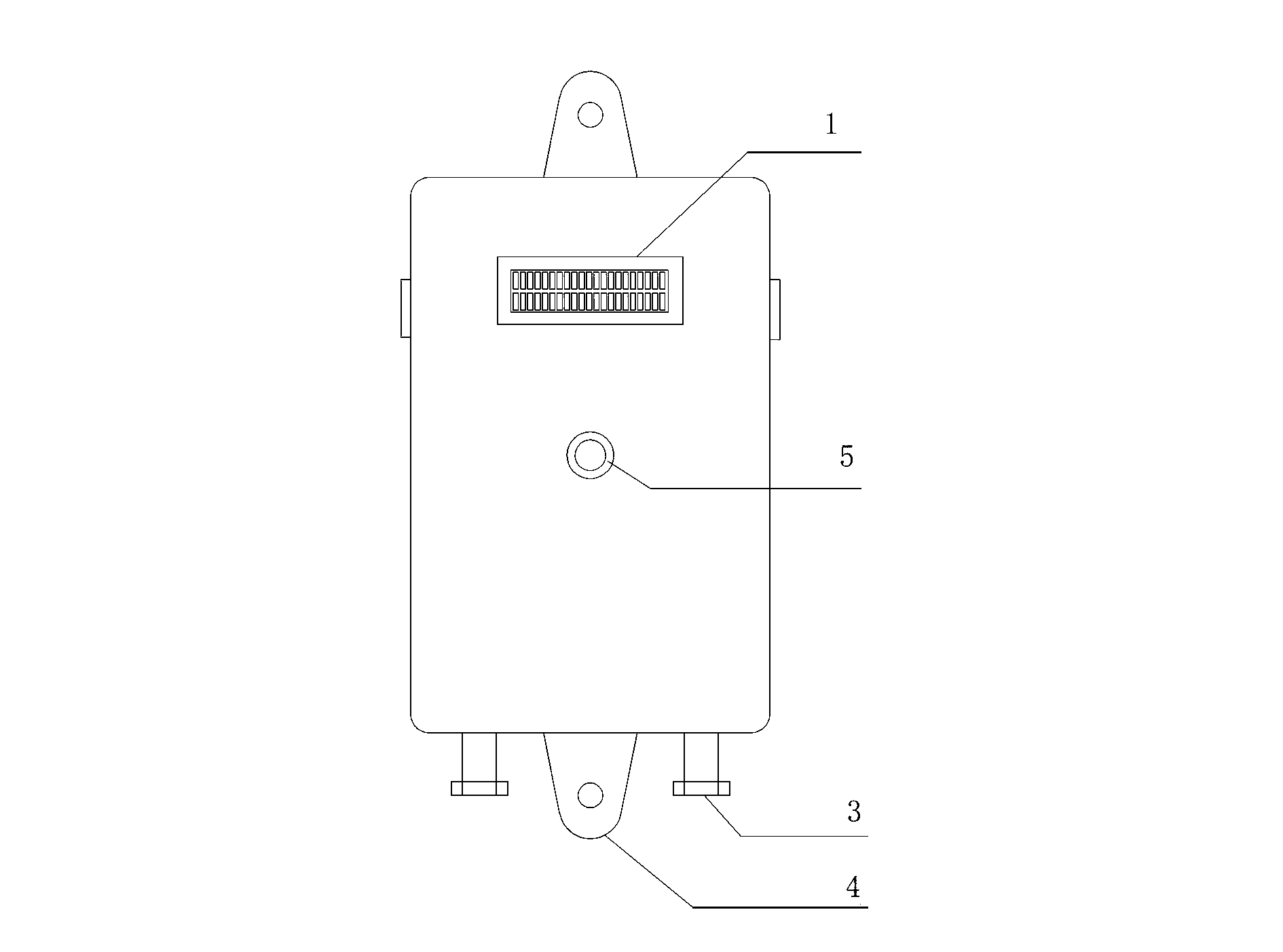

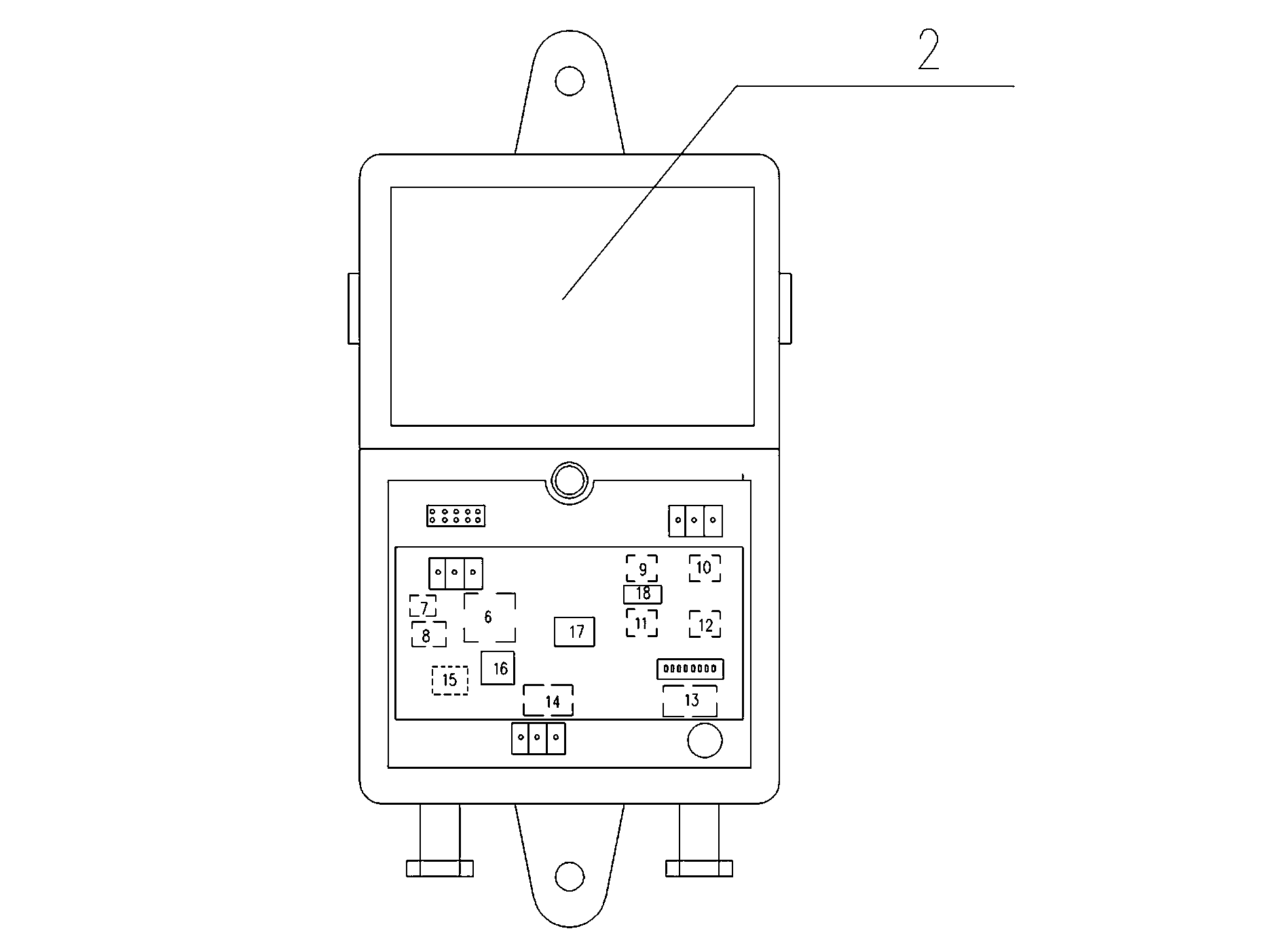

[0026] Outer shell and internal circuit board: the shell is provided with an outer cover 5, and the outer cover 5 has a display window 1, and the LED display is installed on the end cover to display from the window; the outer cover 5 is also provided with a protrusion 4, a cable Threading holes and sockets 3; the internal circuit board includes: a sensor part, a central processing unit MCU 6, a protection circuit and a communication circuit 15, a storage circuit 7, a signal measurement and conversion circuit 9, and a capacitor 14. Wherein the transformer 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com