Liquid crystal display device and mould

A technology of a liquid crystal display device and a liquid crystal display module, which is applied in the direction of lighting devices, lighting auxiliary devices, lighting device components, etc., can solve the problems of complex assembly process, time-consuming and labor-intensive, etc., to reduce manufacturing costs, reduce component types, The effect of reducing the production cost of injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

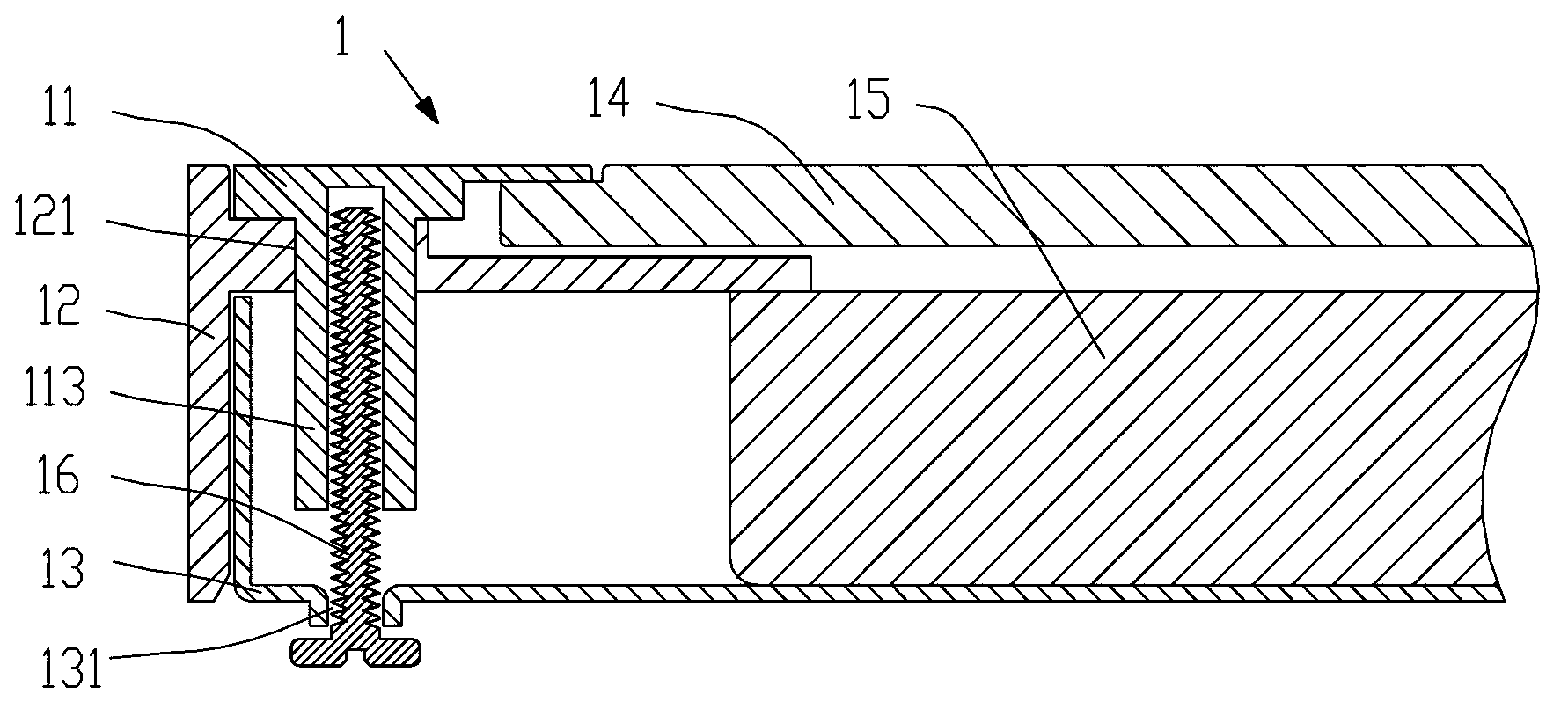

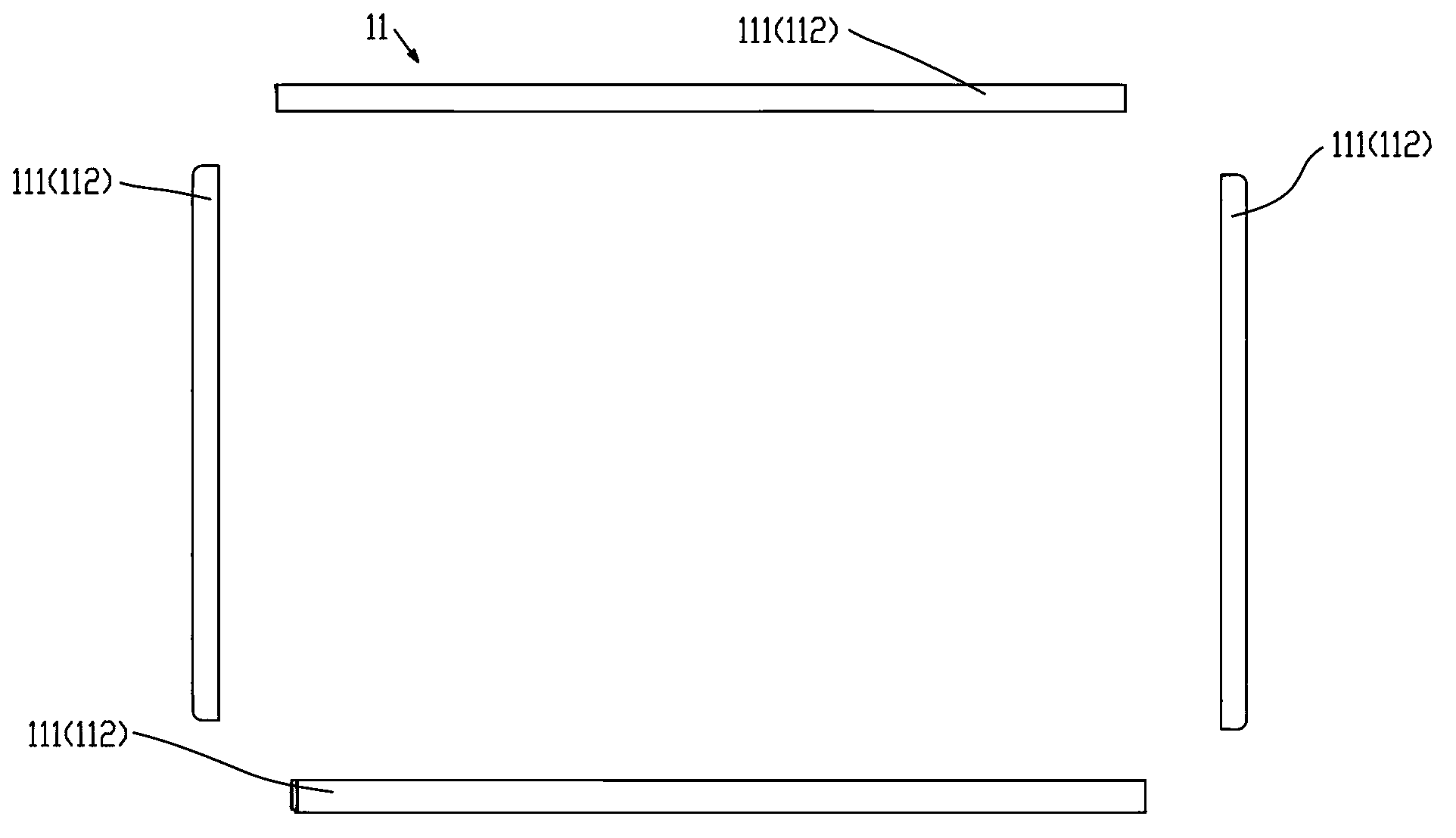

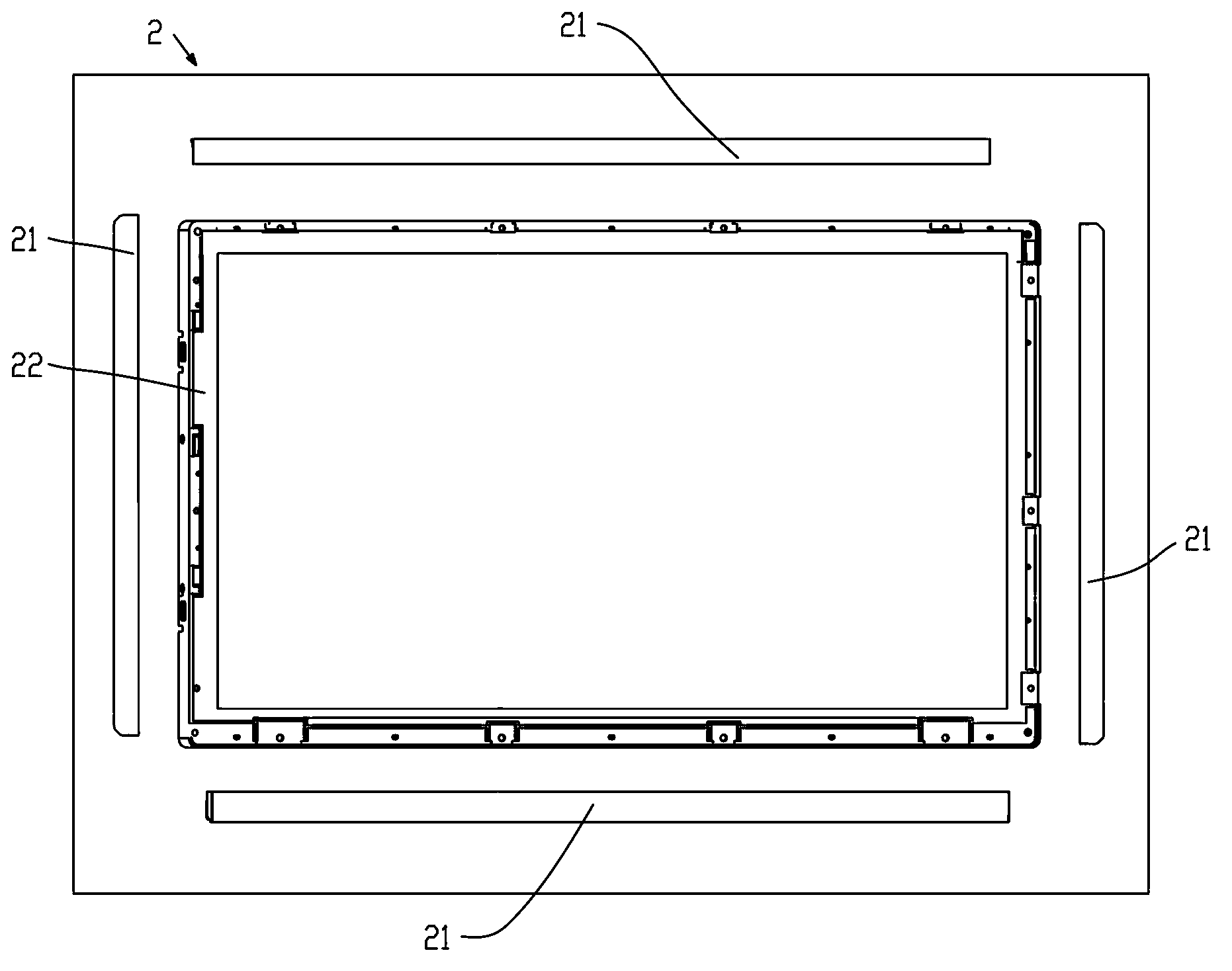

[0021] The invention discloses a liquid crystal display device. The liquid crystal display device can be a liquid crystal display for computers, a liquid crystal panel computer, or a liquid crystal TV. As an embodiment of the liquid crystal display device of the present invention, as figure 1 and figure 2 As shown, the liquid crystal display device includes a liquid crystal display module 1, and the liquid crystal display module 1 includes a front frame 11, a middle frame 12, a back plate 13, a liquid crystal display panel 14 and a backlight module 15, and the liquid crystal display panel 14 is set Between the front frame 11 and the middle frame 12, the backlight module 15 is arranged between the middle frame 12 and the back plate 13, the front frame 11 is also used as the front shell of the liquid crystal display device, and the back plate 13 is shared It is the back cover of the liquid crystal display device. The front frame 11 is a split structure and includes a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com