Rapid high-precision photovoltaic array maximum power point tracking control method

A technology of maximum power point and photovoltaic array, which is applied in the field of solar photovoltaic power generation, can solve problems such as energy waste and system instability, and achieve the effects of economical reliability, guaranteed continuity, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

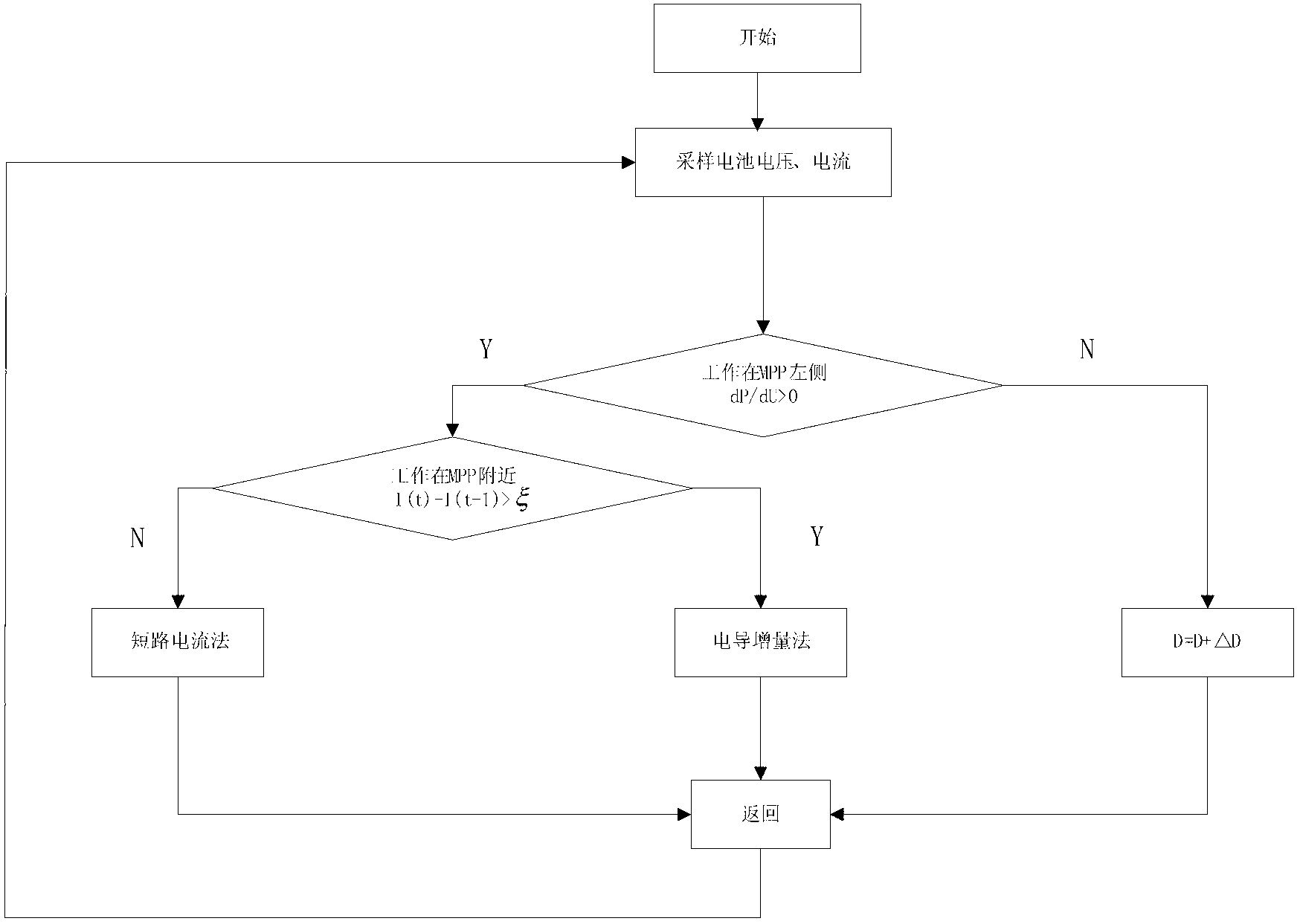

[0020] 1) Define a certain working time of the system as t, sample the output voltage and output current of the photovoltaic cell at time t, and calculate the output power;

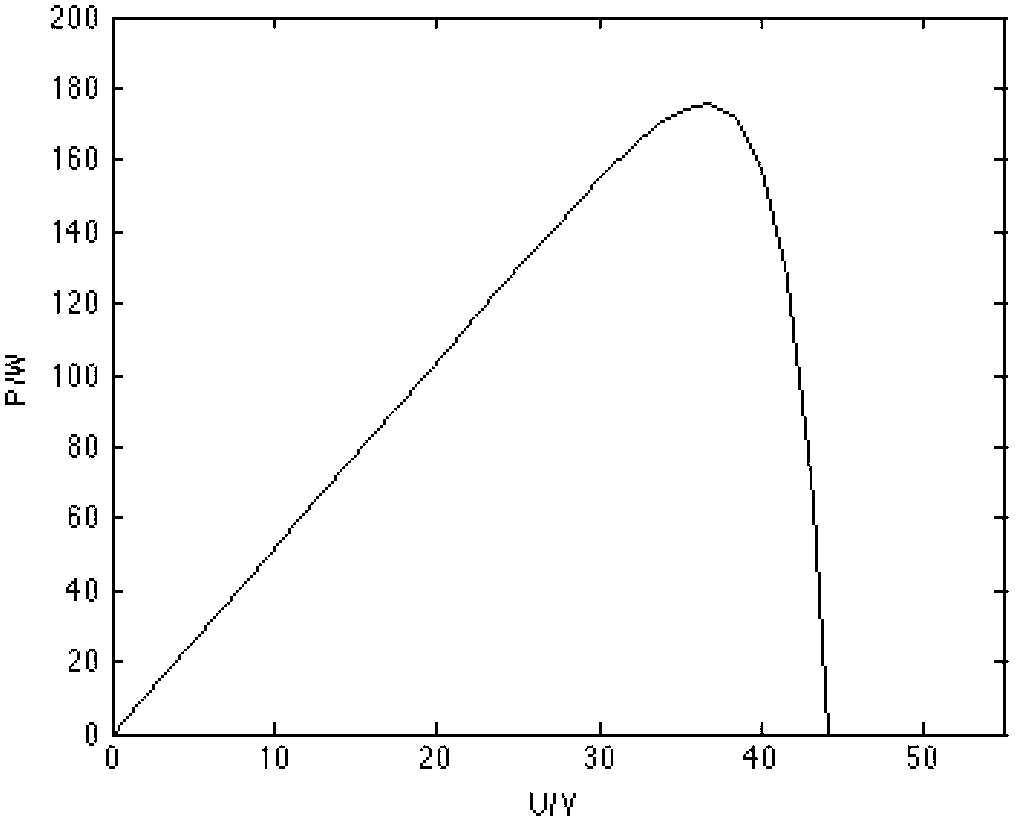

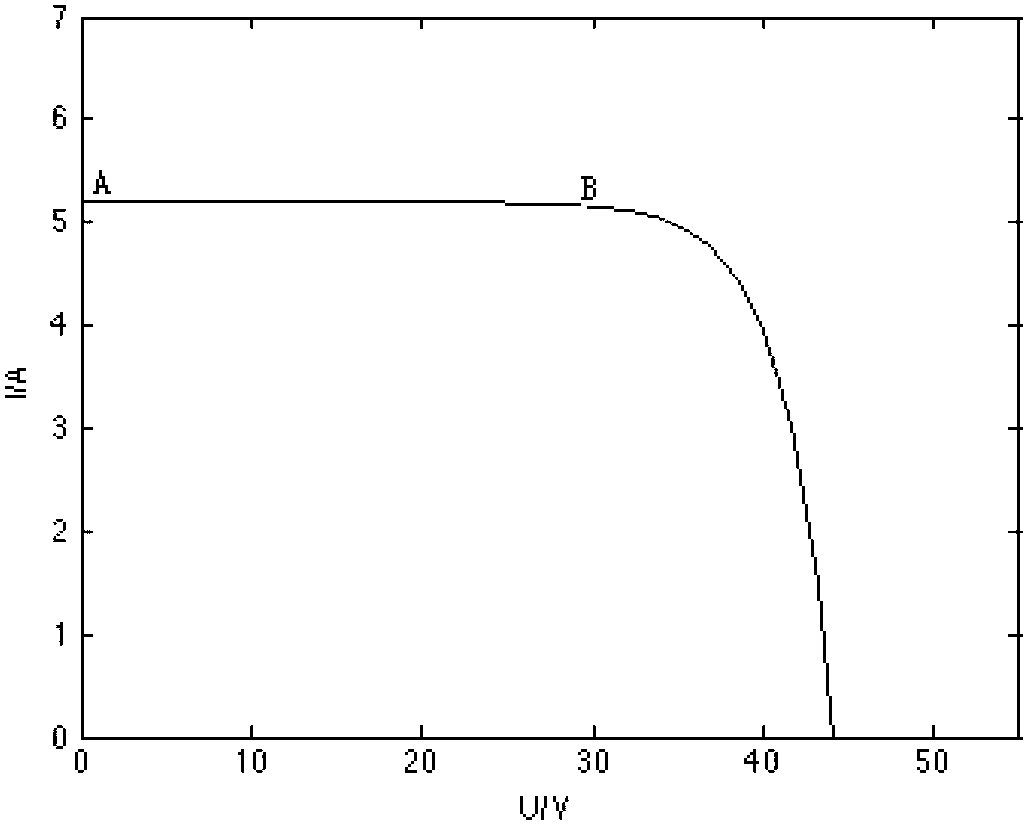

[0021] 2) Compare the power and voltage at time t with the power and voltage at time t-1, and judge whether the system is working on the left side of the maximum power point according to the positive or negative of dP / dU, where dP refers to the adjacent sampling time dU refers to the voltage difference at adjacent sampling moments, and the left side of the maximum power point refers to: the voltage at the system operating point is less than the voltage at the maximum power point;

[0022] 3) If the system operating point is not on the left side of the maximum power point, adjust the duty cycle so that the system works on the left side of the maximum power point;

[0023] 4) Make sure that the system works on the left side of the maximum power point, then use the formula I(t)=dP(t) / dU(t) to get I(t) and I(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com