Series excited motor for motor-driven rotary cultivator

A technology of series excitation motor and rotary tiller, which is applied in the fields of tillage implements, electric components, agricultural machinery and implements, etc., can solve the problem that the electric rotary tiller cannot meet the safety requirements, restrict the production and sales of electric rotary tiller, and the product launch. and other problems to achieve the effect of improving cooling effect, reducing wind energy and reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

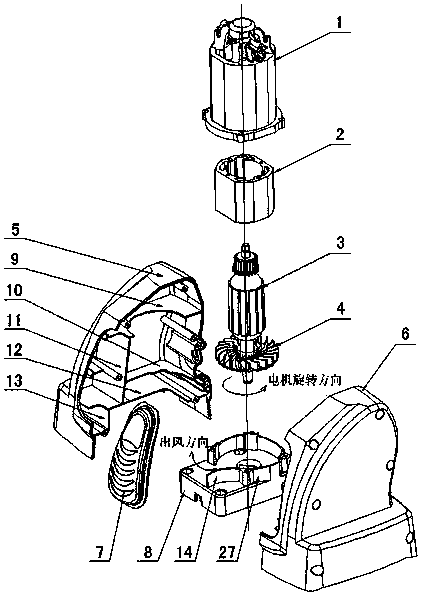

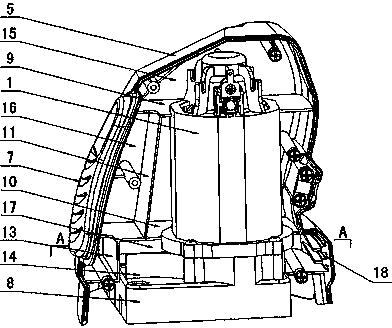

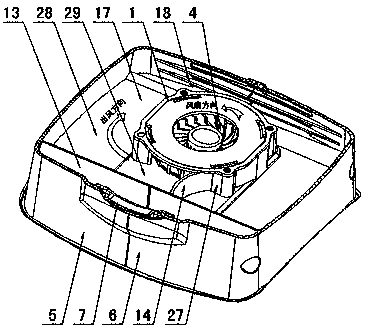

[0020] Figure 1 to Figure 5 As shown, the present invention creates a specific embodiment of a series-excited motor for an electric rotary tiller, which includes a motor barrel 1, a stator 2, a rotor 3, a centrifugal fan 4, left and right casings 5, 6, and an air intake grille 7 , the middle cover 8, the left and right casings 5,6 are correspondingly provided with: left and right partition plates 13,22, air inlet left and right partitions 11,20, left and right upper partitions 9,19, left and right lower partitions 10,21, air outlet The left and right dividing plates 12,23, the motor barrel 1 are correspondingly installed between the left and right upper dividing plates 9,19 and the left and right lower dividing plates 10,21, the middle cover 8 is correspondingly installed between the left and right dividing plates 12,23 of the air outlet, and the air inlet The grid plate 7 is fixedly connected with the left and right casings 5, 6, and the left and right casings 5, 6 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com