Lithium ion secondary battery

A secondary battery and lithium ion technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve technical difficulties and other problems, and achieve the effects of reducing manufacturing costs, miniaturization costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

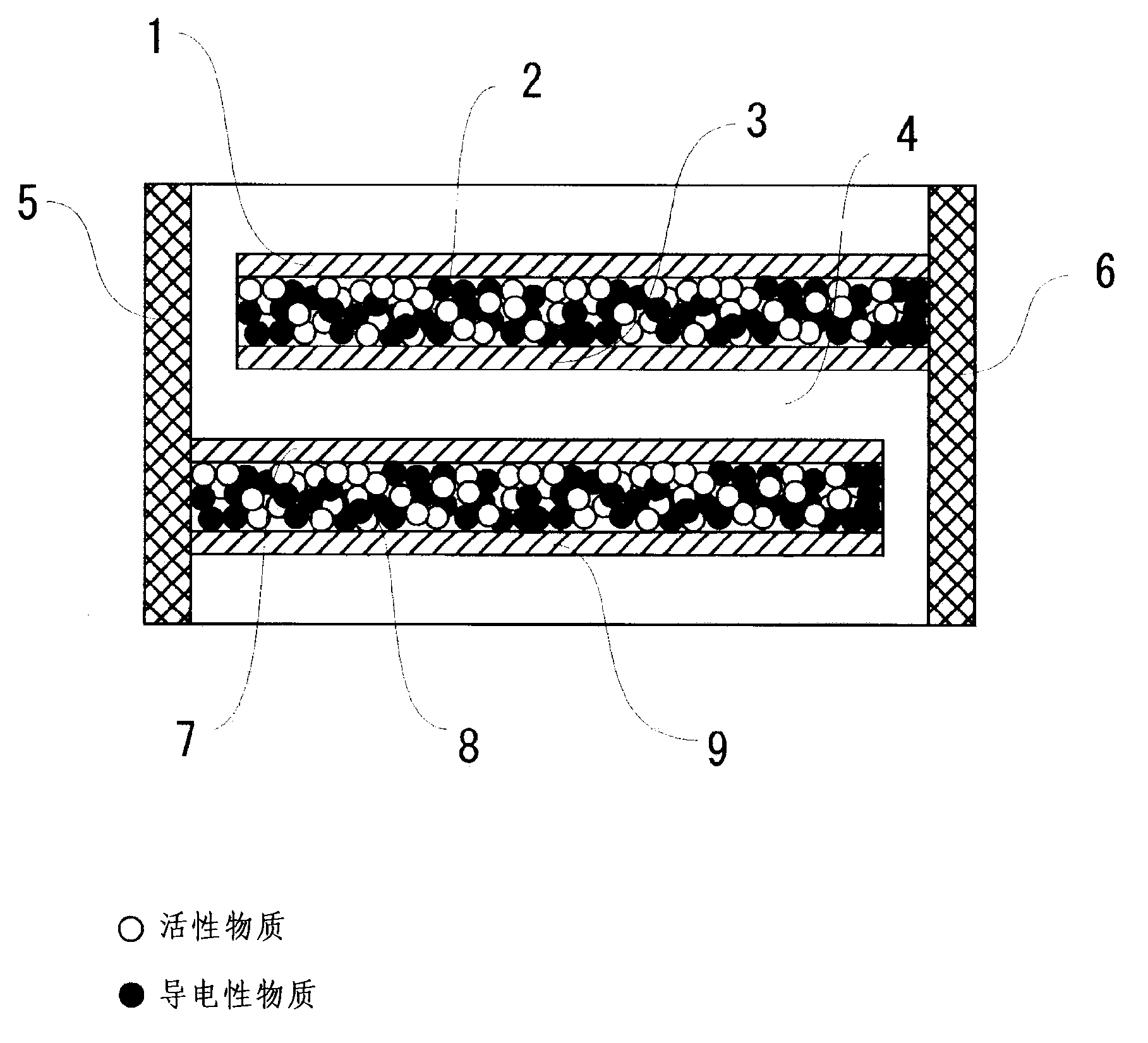

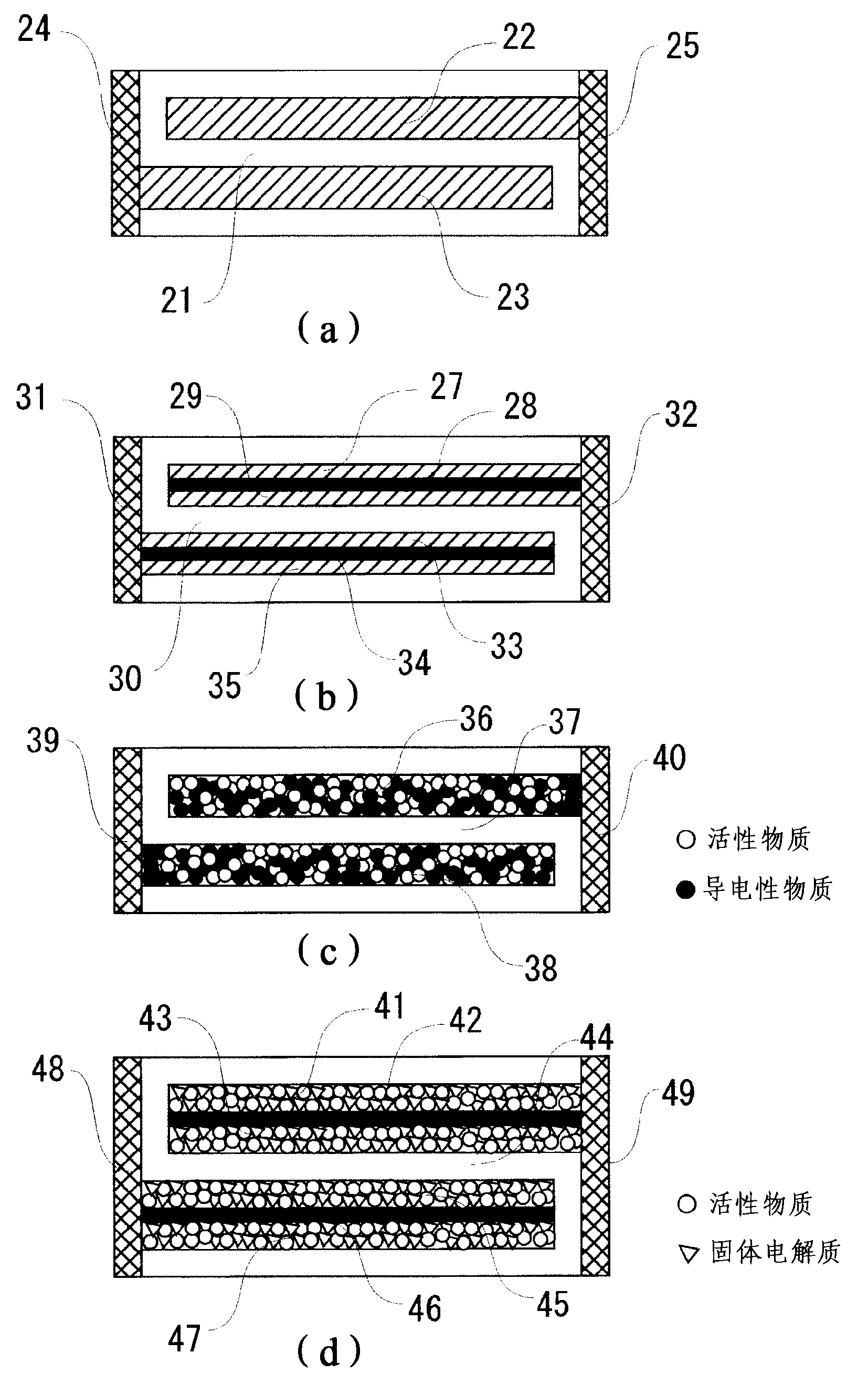

Embodiment 1)

[0166] The present invention will be described in detail below using examples. However, the present invention is not limited to these Examples. In addition, a part means a weight part unless otherwise indicated.

[0167] (making active substances)

[0168] The active material used Li produced by 2 MnO 3 .

[0169] With Li 2 CO 3 and MnCO 3 Weigh the starting materials so that their substance content ratio is 2:1. These materials were wet-mixed for 16 hours with a ball mill using water as a solvent, and then dehydrated and dried. The obtained powder was pre-fired at 800°C in air for 2 hours. Coarsely pulverize the calcined piece, wet-mix with water as a solvent with a ball mill for 16 hours, and then dehydrate and dry to obtain active material powder. The average particle diameter of this powder was 0.40 μm. Using an X-ray diffraction device, it was confirmed that the powder component produced was Li 2 MnO 3 .

[0170] (making active material slurry)

[0171] 15 ...

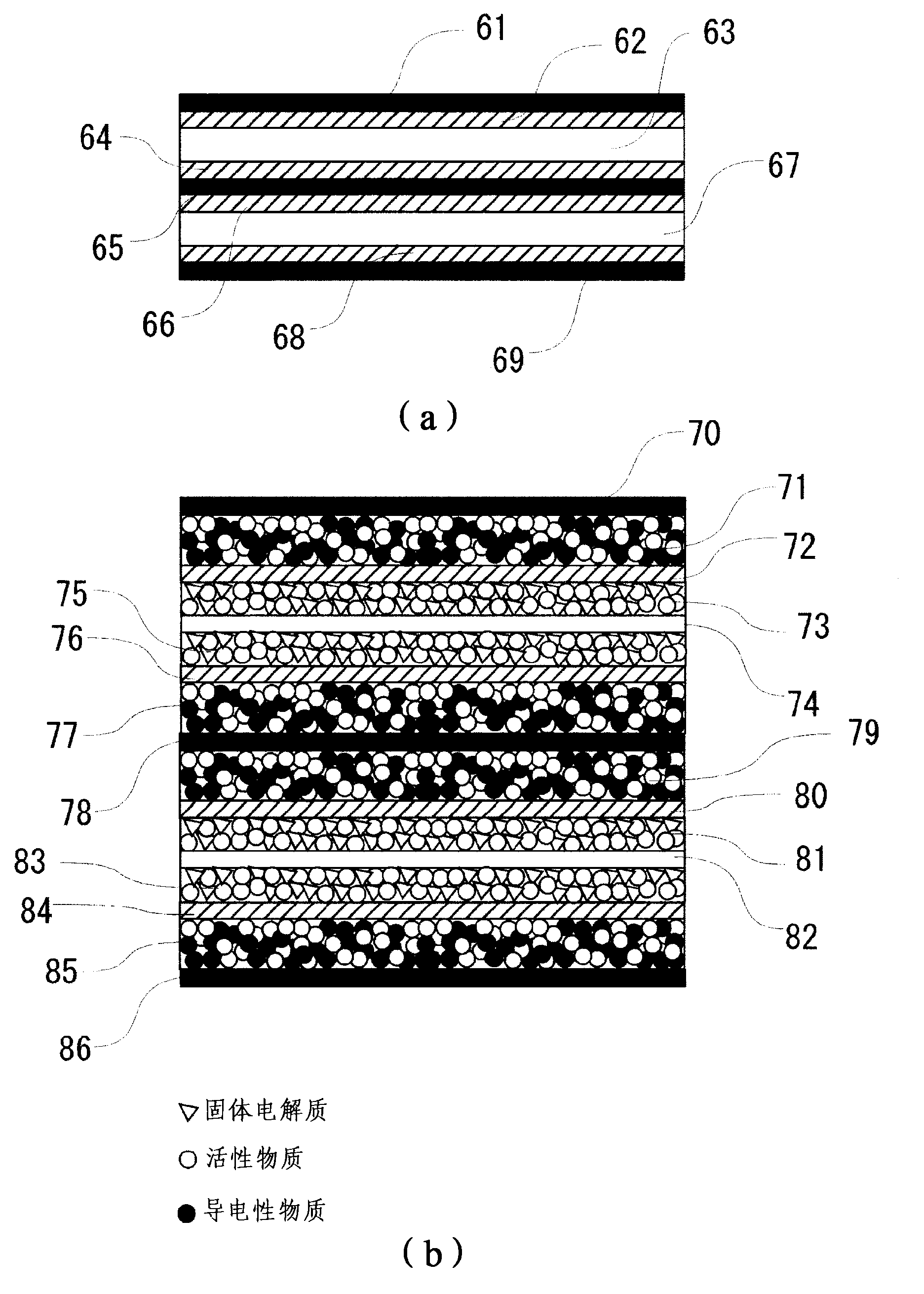

Embodiment 2)

[0189] An all-solid secondary battery was produced by the same manufacturing process as in Example 1, except that only the active material mixed current collector slurry was coated on the inorganic solid electrolyte sheet and dried to form an active material unit. The thickness of the active material mixed current collecting electrode of the produced battery was 7 μm.

[0190] A series of sintered batteries have an appearance size of 3.7mm×3.2mm×0.35mm.

[0191] (Evaluation of battery characteristics)

[0192] Lead wires were attached to each terminal electrode, and charge and discharge tests were repeated. The measurement conditions are as follows. That is, the current at both charge and discharge was set to 0.1 μA. In addition, the cut-off voltages at the time of charging and at the time of discharging were 4.0V and 0.5V, respectively. The results are shown in Figure 7 . From the results, it was confirmed that the produced nonpolar lithium ion secondary battery of the...

Embodiment 3)

[0196]The inventors of the present application found that the active material material that can be used as an active material of a nonpolar battery is not limited to use in an all-solid-state secondary battery, but can also be used in a wet secondary battery, and it can be seen that it shows excellent battery characteristics. The manufacturing method, evaluation method and evaluation results of the wet battery will be described below.

[0197] The active material, ketjen black and polyvinylidene fluoride were mixed in a weight ratio of 70:25:5. Further, N-methylpyrrolidone was added to the mixture to obtain active substance slurry. Thereafter, the active material slurry was uniformly coated on the stainless steel foil with a doctor blade, and then allowed to dry. Stainless steel sheets coated with active substances are used punch punching. The sheet (hereinafter referred to as "disk electrode") was degassed and dried under vacuum at 120°C for 24 hours, and its weight was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com