Automatic pulverizer for coal sample

An automatic coal sample preparation technology, applied in grain processing, etc., can solve the problems of high noise in the working environment, heavy manual workload, dust pollution, etc., and achieve the effect of no dust pollution, high degree of automation, and fast sample preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

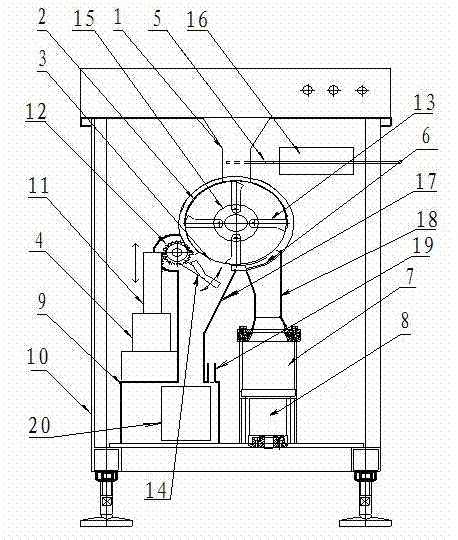

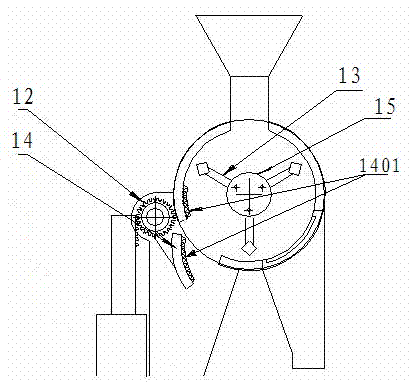

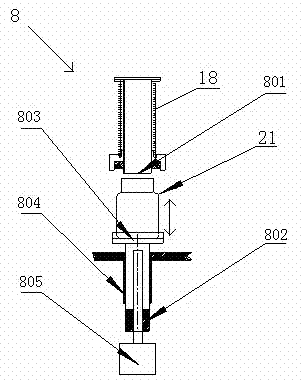

[0017] see figure 1 , the coal sample automatic pulverizer comprises a frame 10, and the frame 10 is provided with a feed hopper 1, a crushing device, a sampling device and an impurity discarding device; the feed hopper 1 is located on the top of the frame 10, and the feed hopper 1 The exit of the door is provided with a dodge door 5, and the dodge door 5 is connected with the second drive device linear motor 16 (the dodge door 5 can also be manually driven), and the second drive device can also use a motor to drive the dodge door 5 through gears and racks. Method; the crushing device adopts a high-speed centrifugal pulverizer as the main body of pulverized coal, including a cavity 2, and a hammer body 13 is arranged in the cavity 2, and the hammer body 13 is hinged on the turntable 15 connected with the motor of the first driving device, and the cavity 2 The upper part is provided with a feed port connected to the feed hopper 1, and the lower part of the cavity 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com