Double working position air pressure movement molding machine

A molding machine and dual-station technology, applied in molding machines, casting molding equipment, manufacturing tools, etc., can solve the problems of unimproved economic benefits of enterprises, high labor intensity of workers, slow molding speed, etc. The effect of high work efficiency and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

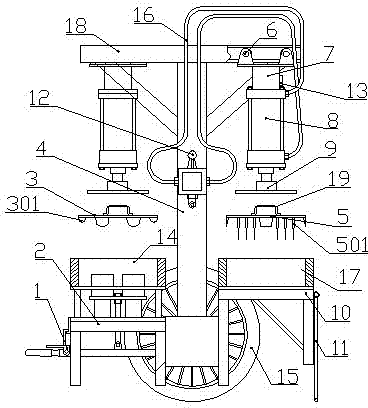

[0014] Now in conjunction with the accompanying drawings, the technical content of the utility model is further described.

[0015] Such as figure 1 As shown, the workbench includes a first workbench and a second workbench, the first workbench and the second workbench are arranged on the same level, and the first workbench includes a leaky mold mechanism 1, a leaky mold 2 , the sand box bottom box 14 that is arranged on the leakage mold 2 and the bottom box pressing plate 3 that is used to cover the sand box bottom box 14, the second workbench includes a support frame 11, a cover box mold frame 10 that is arranged on the support frame 11 , the cover box 17 and the cover box pressing plate 5 for the cover cover box 17, a frame column 4 is arranged on the body between the two workbenches, and the top of the frame column 4 is fixedly connected with a horizontally arranged guide rail 18, A movable rocker arm provided with a pressing plate 9 can be reciprocally slidably mounted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com