Metal paint, and preparation method and application thereof

A technology for metal coatings and metal workpieces, applied in epoxy resin coatings, coatings, devices for coating liquid on the surface, etc., can solve the problems of low efficiency of zippers, poor coating effects, etc., and achieve good effects and washing effects Good, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] 1. According to Example 1 in Table 1, add each component in turn and stir to form a mixed coating component A.

[0052] 2. According to Example 4 in Table 2, add each component in turn and stir to form the coating component B.

[0053] 3. According to Example 7 in Table 3, add each component in turn and stir to form a diluent.

[0054] 4. Fully mix Example 1 and Example 4 at a volume ratio of 1:1. Add 1 part of the mixed oil to 3 parts of Example 7 and stir evenly, put it into the metal zipper workpiece to be coated and soak for 10-30 seconds, take it out and let it dry naturally, then put it in a 120°C oven and bake for 30 minutes.

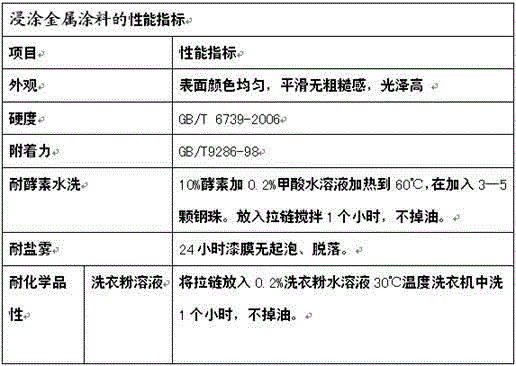

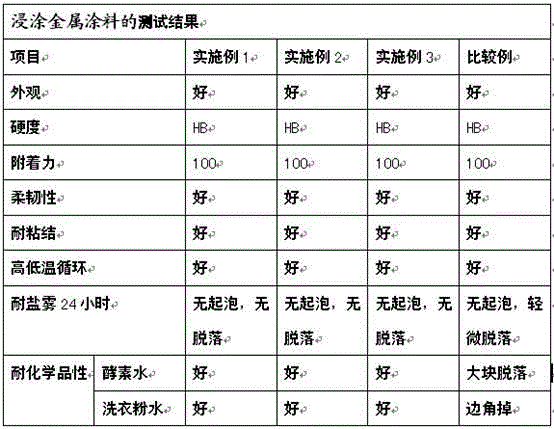

[0055] 5. Repeat steps 1-4 alternately according to the embodiment in Table 1, Table 2, and Table 3. The performance test conditions are shown in Table 4, and the test results are good, as shown in Table 5.

[0056] Table 1: Component A Coating Examples (weight percent)

[0057]

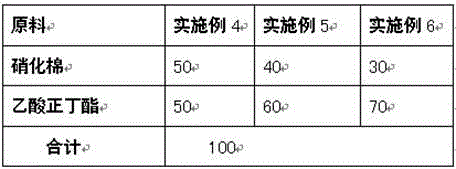

[0058] Table 2: Component B Examples (percentage by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com