A gas-dynamic automatic vertical drilling tool with partial gravity

A gas dynamics, vertical drilling technology, applied in directional drilling and other directions, can solve the problems of affecting the ROP, difficult to generate declination force, low pressure difference, etc., and achieve the effects of convenient operation, stable performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

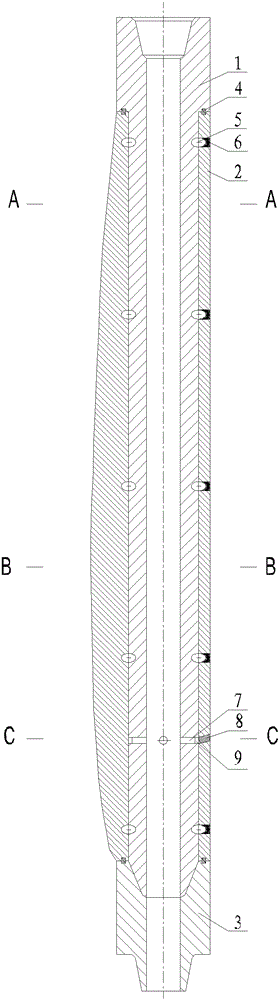

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0037] Such as figure 1 As shown in the figure, a partial-weight aerodynamic automatic vertical drilling tool includes a core pipe 1, a lower joint 3 and an eccentric outer cylinder 2;

[0038] The heart tube 1 and the lower joint 3 are both tubular structures, and the central holes of the two are connected; the upper end of the lower joint 3 has a notch, and the lower end of the heart tube 1 is placed in the notch on the lower joint 3, and is connected with the The lower joint 3 is connected by threads;

[0039] There is a shoulder on the upper part of the core tube 1, and the eccentric outer cylinder 2 is set on the outside of the core tube 1, and its upper end surface is stuck at the shoulder of the core tube 1, and the lower end surface withstands the upper end surface of the lower joint 3;

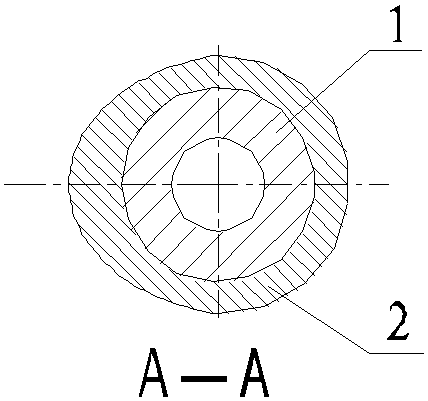

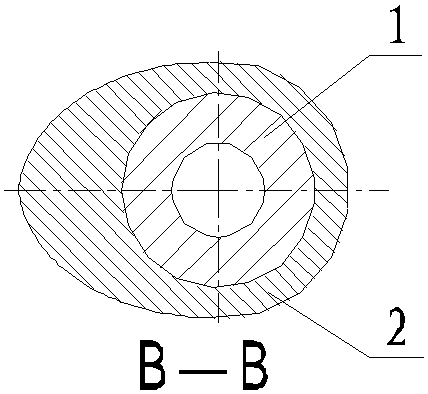

[0040] The outer contour line of the transverse section of the eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com