Steering oil cylinder of loader

A technology for steering oil cylinders and loaders, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of high working frequency, poor working environment, and long working hours of loaders, and achieve good sealing performance, simple and compact structure, and not easy to loosen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

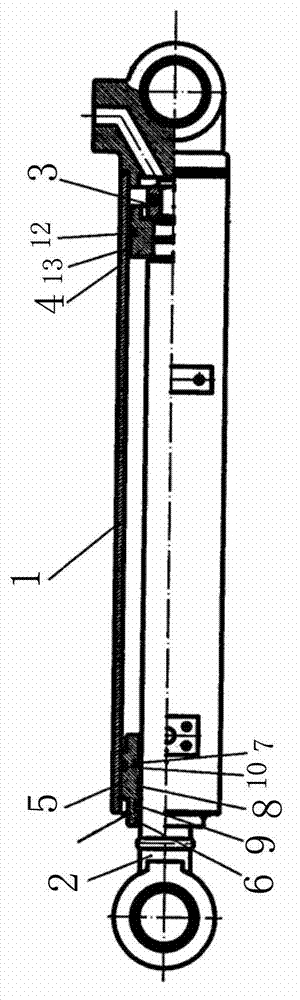

[0010] Such as figure 1 As shown, the present invention is provided with a piston rod 2 inside the cylinder 1, a piston 4 is locked at one end of the piston rod 2 through a lock nut 3, and the piston rod 2 is sleeved in the cylinder through a guide sleeve 5, and the guide A dust-proof ring 6, a step seal 7, a first support ring 8, a piston rod sealing ring 9, an O-ring 10, and a retaining ring 11 are installed in the outer diameter and inner diameter groove of the sleeve 5, and a grid is installed on the piston 4. Lai ring 12, the second support ring 13. Through the above settings, when the piston rod 2 is extended and retracted in the present invention, the gray ring 12 on the piston 4 acts as a main seal, and the second support ring 13 provides lateral support; the dust-proof ring 6 on the guide sleeve 5 scrapes In addition to external impurities to prevent damage to the seal from entering the oil cylinder, the piston rod sealing ring 9 compresses the piston rod 2 and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com