Cassettes for sintering ceramic concentric spheres

A technology of sintering ceramics and concentric spheres, which is applied in the field of handicraft manufacturing, and can solve problems such as easy cracking and deformation, easy deformation, and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

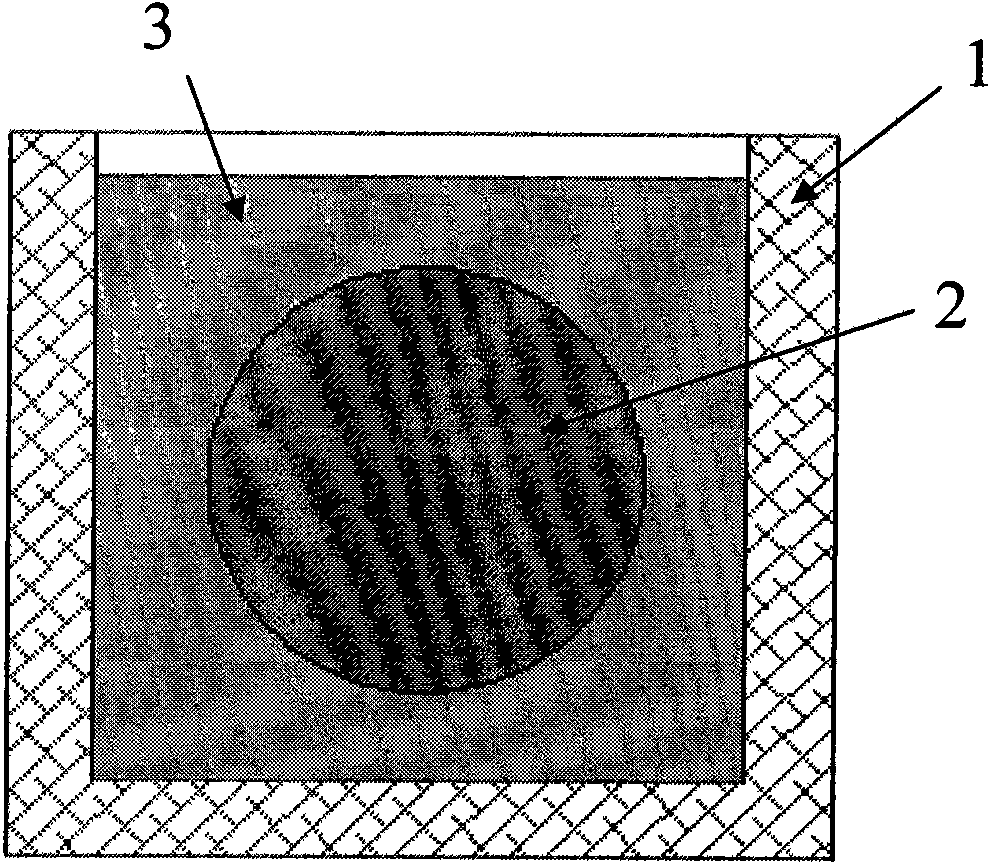

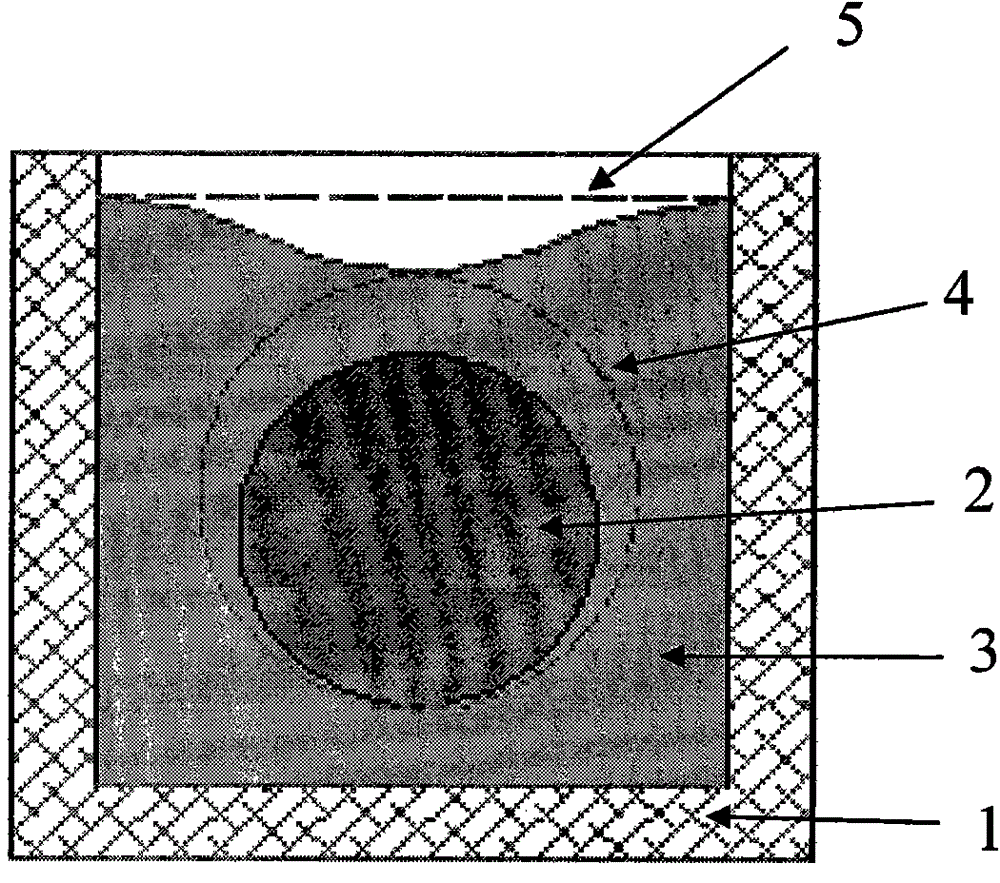

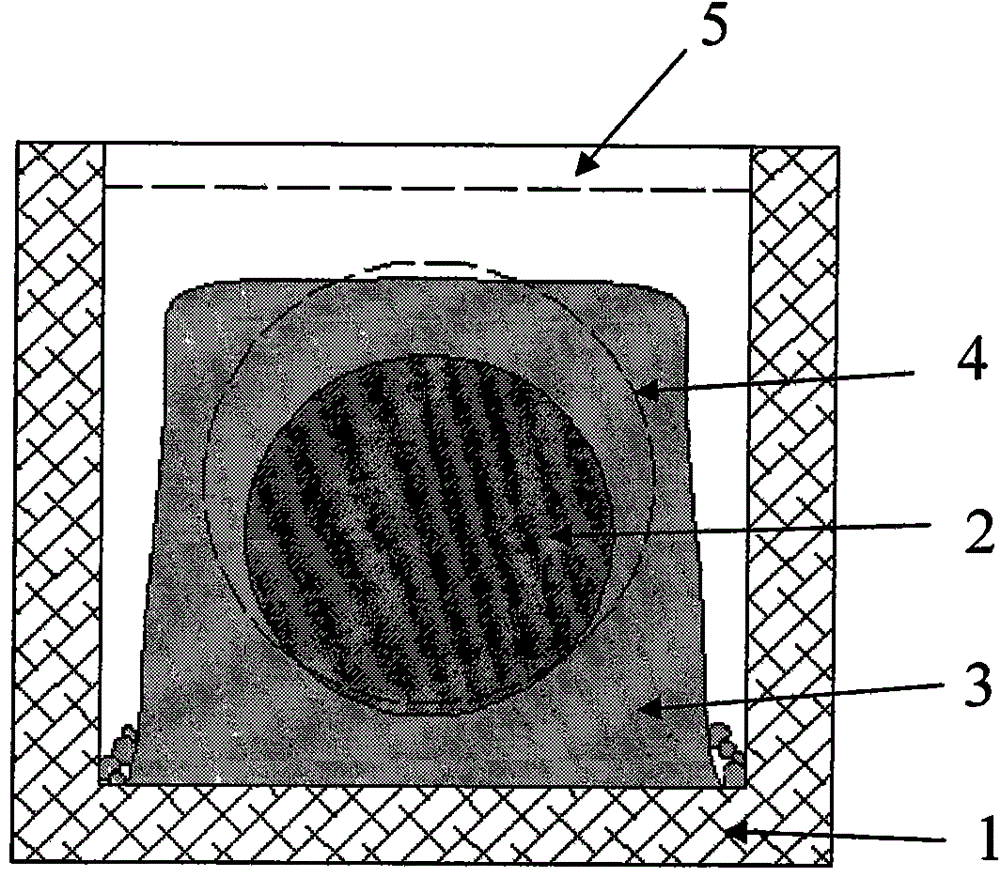

[0018] As shown in the figure, the present invention discloses a method for sintering ceramic concentric spheres using a V-shaped cross-section box bowl, including the following steps:

[0019] Step 1, according to the sintering shrinkage of ceramic concentric spheres, determine the proportion of organic matter powders such as sawdust to be added in the alumina fine powder;

[0020] Step 2: Design a V-shaped inverted cone-shaped box bowl according to the size of the ceramic concentric spheres. The apex angle of the inner cavity section of the box bowl is 60°, and the cone shape is conical or regular pyramid. smooth;

[0021] Step three, such as Figure 4 As shown, put the alumina fine powder 3 added with sawdust and other organic matter powders at the bottom of the V-shaped inverted conical box bowl 1, and carefully put the prepared ceramic concentric sphere body 2 on the alumina fine powder 3, Then add alumina fine powder 3 and fill the ceramic concentric ball body 2, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com