Pin trimming device for dip package ic chip based on recycling

A technology for trimming devices and pins, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems that affect the accuracy of trimming, cannot be handled by bending or skewed pins, and are prone to shaking, and achieve high accuracy. , Solve the problem of pin trimming, and adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the present embodiment, the structure based on the reclaimed DIP package IC chip pin trimming device is set to:

[0038] Such as Figure 4 The pin coplanar trimming unit shown is to form a coplanar trimming die with a concave lower die 11 and an inverted concave upper die 12, and the joint trimming state of the trimming die is: the chip 15 is placed with the pins facing down On the concave lower mold 11 , the inverted concave upper mold 12 is buckled on the chip 15 and clamps the chip 15 with the concave lower mold 11 . The coplanar trimming of the pins of the DIP-packaged IC chip is accomplished by mold clamping between the concave lower mold 11 and the inverted concave upper mold 12 .

[0039] Such as Figure 5 The shown airflow channel 20 of the convex lower mold, the same airflow channel 20 on the concave lower mold 11 and the concave base 11a, the chip 15 is fixed by an external vacuum pump.

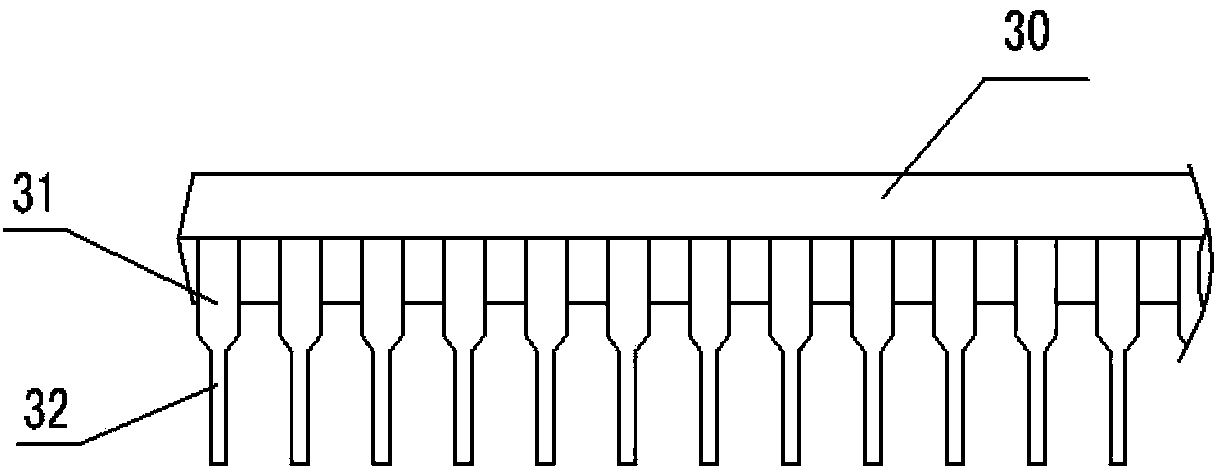

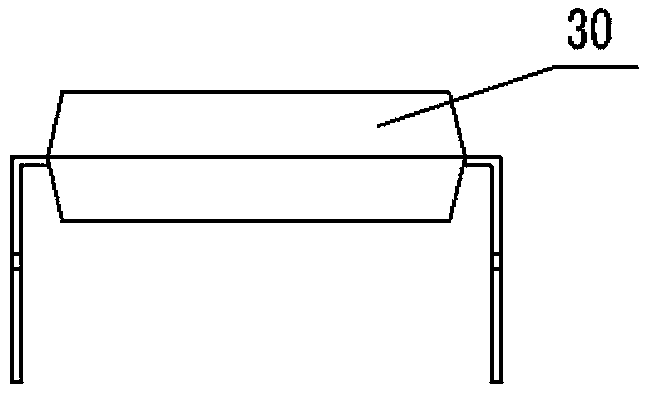

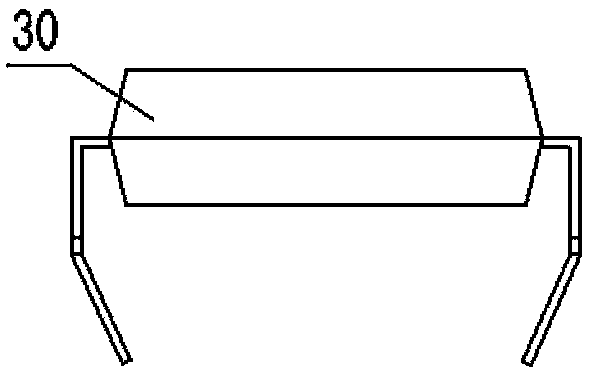

[0040] Such as Figure 6 The shown pin dedendum trimming unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com