Preparation method of functional film of flexible piezoelectric electret

A piezoelectric electret and scalability technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problem of lack of scalability and other problems, and achieve the effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

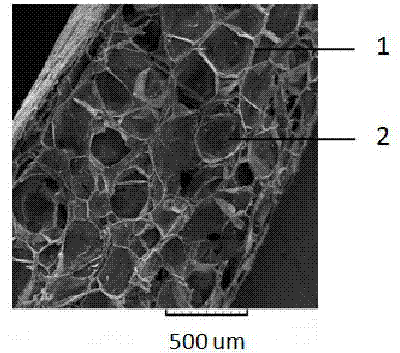

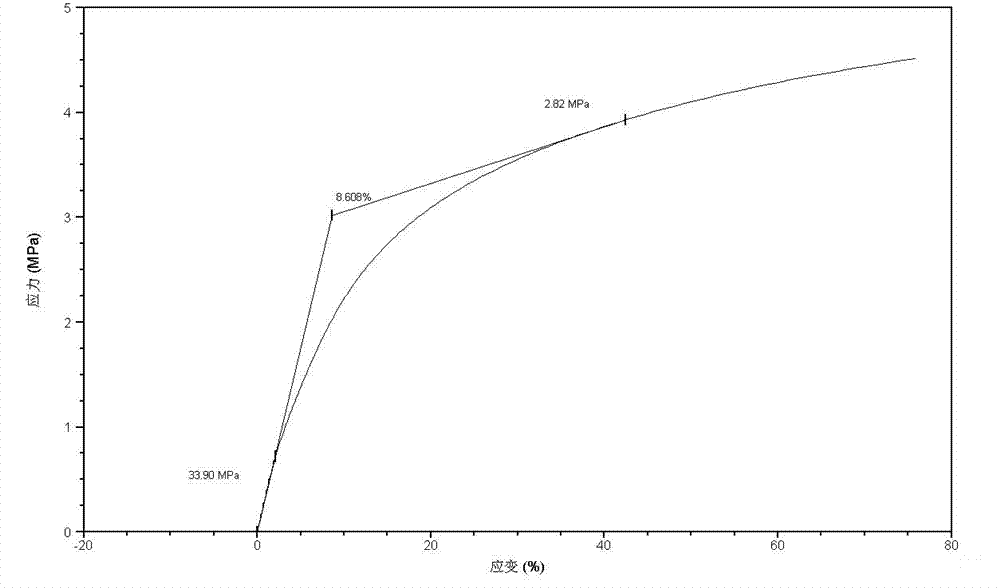

[0027] Example 1 According to the following steps, a cross-linked polypropylene piezoelectric electret 1 with stretchable properties can be obtained.

[0028] 1. First, cut the commercially available 1.5mm thick electron beam cross-linked polypropylene porous structure sheet (ie, foam plastic sheet) into a rectangular sample of 8cm*6cm, and then fix it on a unidirectional stretching machine for stretching and tensioning The stretching area is a 6cm*6cm square area, and the stretching temperature is set at 100 o C. Stop the stretching step when the length of the final stretching zone is 8 cm, and cool the sample to room temperature.

[0029] 2. Place the stretched sample on the hot press for hot pressing. Set the temperature of the press to 70 o C, the hot pressing time is set to 10min, and the pressure of the hot pressing machine is 0.7MPa.

[0030] 3. Perform corona polarization treatment on the above processed samples. The distance between the corona electrode and the sample surf...

Embodiment 2

[0033] Example 2 According to the following steps, a cross-linked polypropylene piezoelectric electret 2 with stretchable properties can be obtained.

[0034] 1. First, cut the commercially available 1.5mm thick electron beam cross-linked polypropylene porous structure sheet (ie, foam plastic sheet) into a rectangular sample of 8cm*6cm, and then fix it on a unidirectional stretching machine for stretching and tensioning The stretching area is a 6cm*6cm square area, and the stretching temperature is set at 100 o C. Stop the stretching step when the length of the final stretching zone is 12 cm, and cool the sample to room temperature.

[0035] 2. Place the stretched sample on the hot press for hot pressing. Set the temperature of the press to 80 o C, the hot pressing time is set to 10min, and the pressure of the hot pressing machine is 0.7MPa.

[0036] 3. Perform corona polarization treatment on the above processed samples. The distance between the corona electrode and the sample sur...

Embodiment 3

[0038] Example 3 According to the following steps, a cross-linked polypropylene piezoelectric electret 3 with stretchable properties can be obtained.

[0039] 1. First, cut the commercially available 1.5mm thick electron beam cross-linked polypropylene porous structure sheet (ie foam plastic sheet) into a rectangular sample of 8cm*6cm, and then place the sample on a hot press for hot pressing. Set the temperature of the press to 70 o C, the hot pressing time is set to 5min, and the pressure of the hot pressing machine is 0.7MPa.

[0040] 2. Fix the stretched sample on a uniaxial stretching machine for stretching. The stretched area is a square area of 6cm*6cm, and the stretching temperature is set at 100 o C. Stop the stretching step when the length of the final stretching zone is 9 cm, and cool the sample to room temperature.

[0041] 3. Perform corona polarization treatment on the above processed samples. The distance between the corona electrode and the sample surface is 4cm, t...

PUM

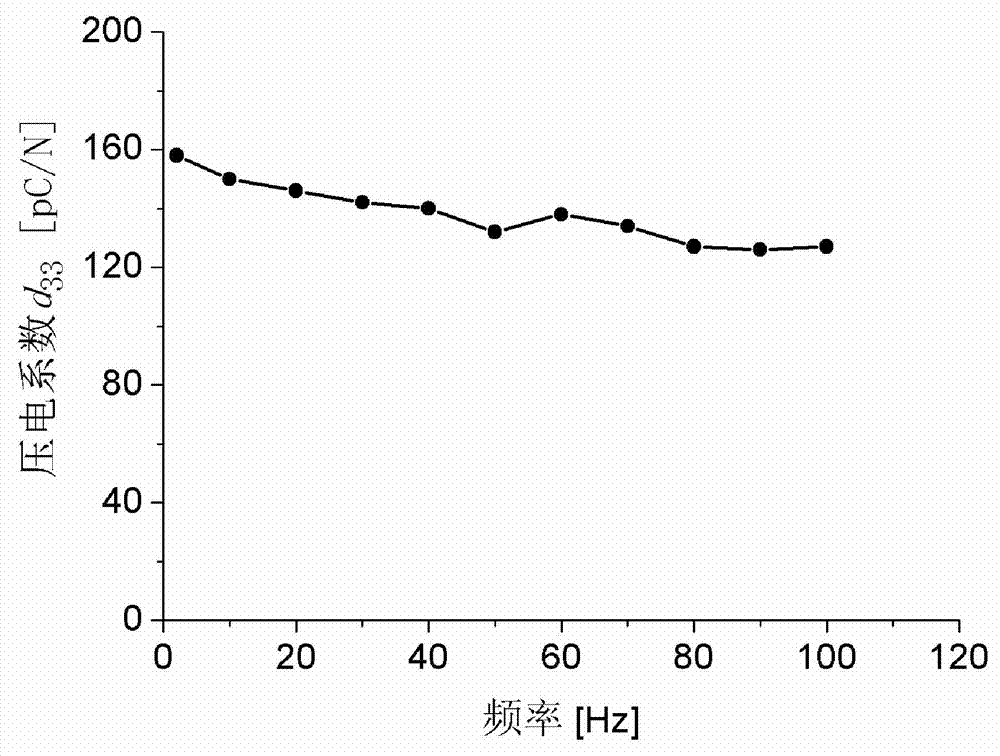

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com