Tilting furnace

A shell and discharge port technology, applied in the field of tilting furnaces, can solve the problems of maintenance material pollution, poisoning, and difficulty in accessing the discharge port, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

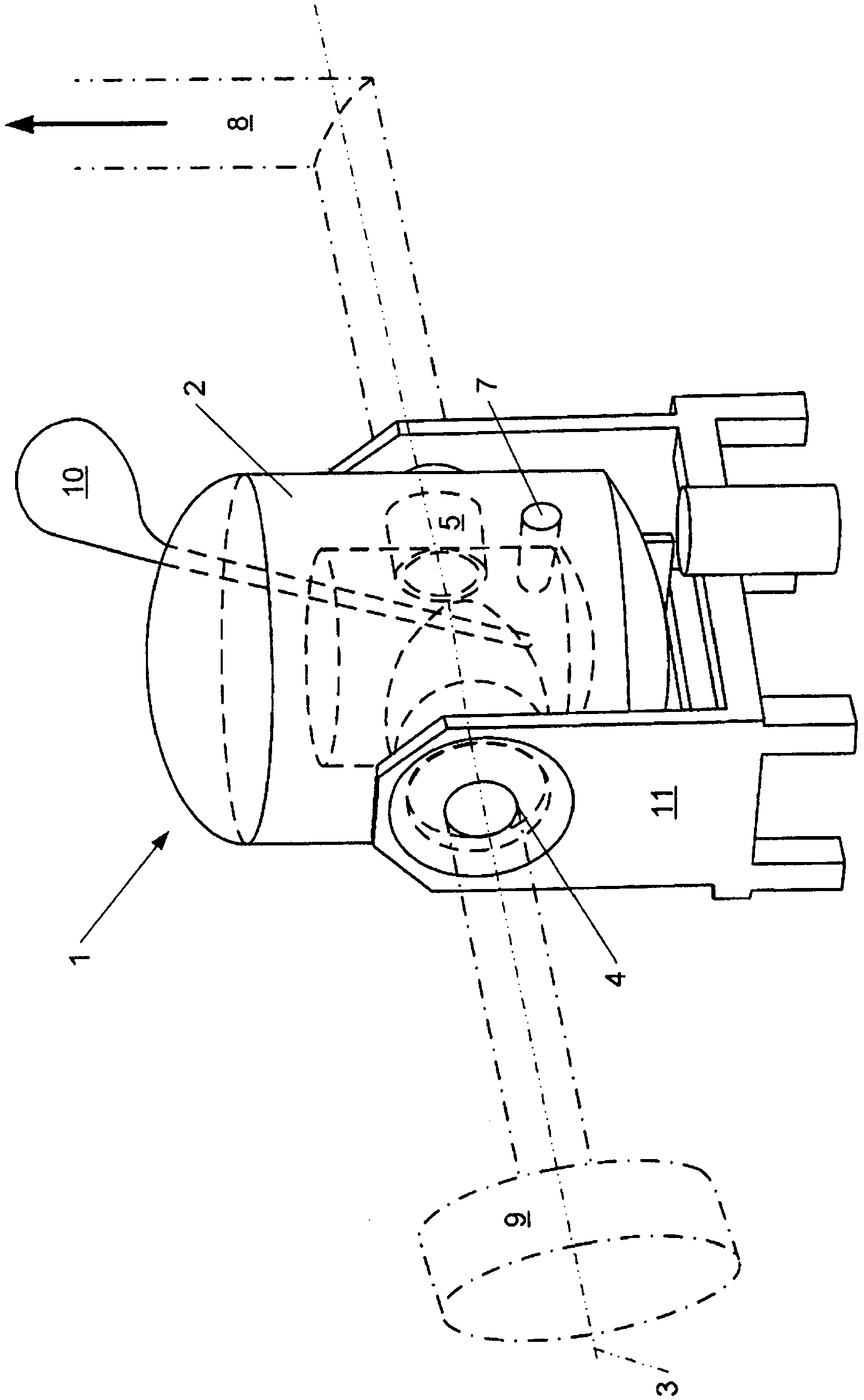

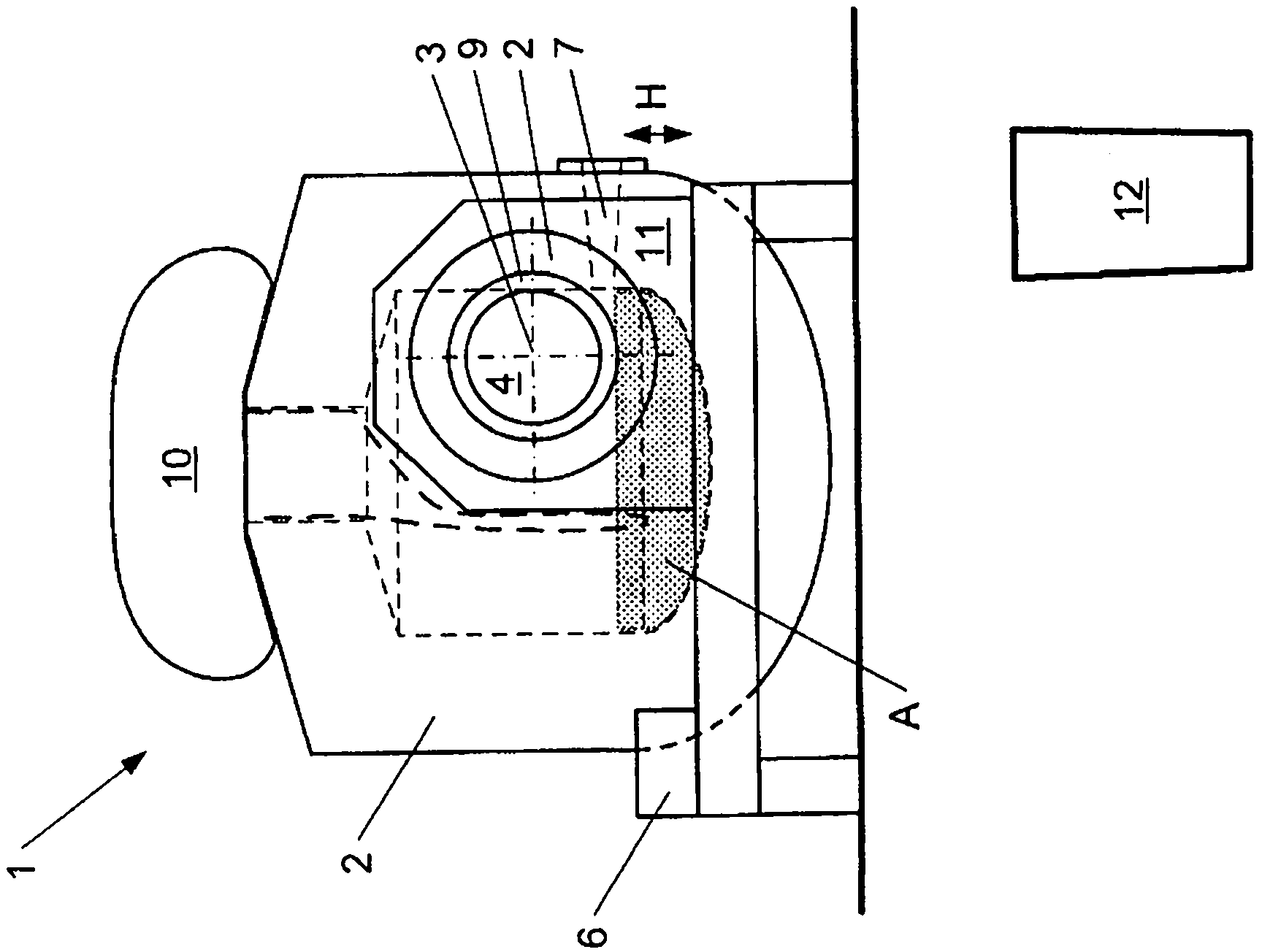

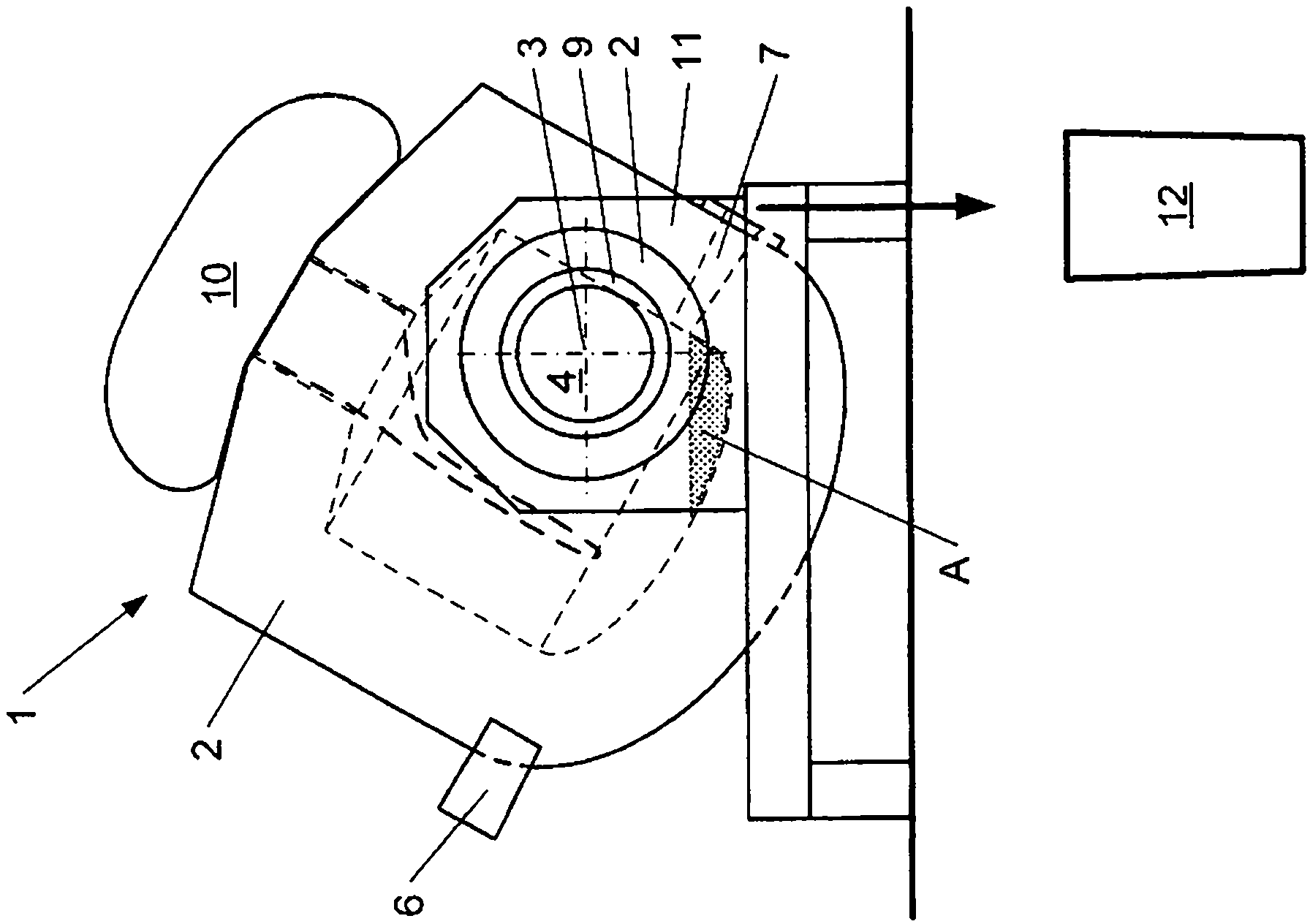

[0017] Hazardous materials such as radioactive or chemically hazardous waste must be brought to a stable state before they can be discharged and / or permanently stored. It is known to process such materials by gasification and / or melting at very high temperatures. If gasification of the material occurs in the presence of oxygen, combustion is predominantly carried out. However, some materials can also be converted to the gas phase in the absence of oxygen. The molten material will be in the form of vitrified slag or a mixture of metal and slag due to the very high temperature, for example up to 15000°C. Hazardous chemicals and / or radioactive compounds are generally contained in the vitrified slag. As a result vitrified slag is a more favorable state for storing this hazardous material in a dump or storage area.

[0018] These very high temperatures can be achieved in a furnace 1 suitable for this. When handling hazardous materials, precautions must especially be considered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com