Pu'er tea paste extraction technology

An extraction process and technology of Pu'er tea paste, applied in the field of extraction process of Pu'er tea paste, can solve the problems of long time consumption, low extraction rate, complicated process and the like, and achieve the effects of simple operation, short time consumption and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

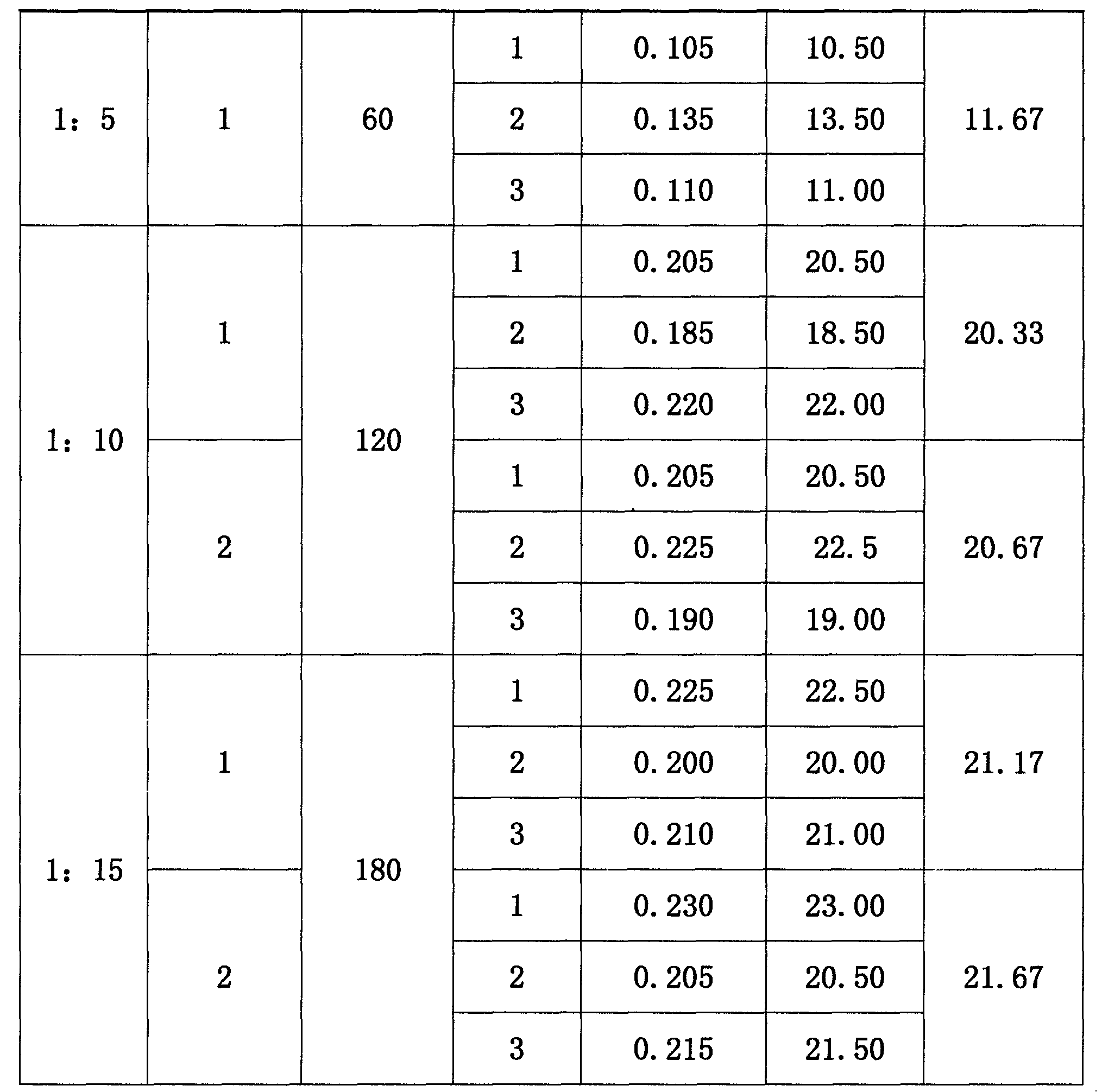

[0010] The present invention selects the material-water ratio and the number of extractions as the influencing factors of the extraction rate of Pu'er tea paste, as shown in Table 1.

[0011] Table 1 The influence of different extraction conditions on the yield of tea extract

[0012]

[0013]

[0014] As can be seen from Table 1, when the ratio of material to water is 1:5, although the concentration time is short, the yield is low, only 11.6%, and the waste of raw materials is large; when the ratio of material to water is 1:10 and 1:15 The yields are both higher, and there is little difference between the two. However, the ratio of material to water increases from 1:10 to 1:15. Although the yield only increases by 0.84%, the concentration time increases by 60 minutes.

[0015] It can be seen from Table 1 that the extraction rate increases when the number of extractions is increased; however, it must be considered that the extraction time, filtration times, and concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com