Flange connecting type multipurpose machining mechanism for side holes

A processing mechanism, multi-purpose technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity of workers, products difficult to meet design requirements, unstable product quality, etc., to improve processing quality. and stability, good appearance quality and precision, and the effect of shortening product delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

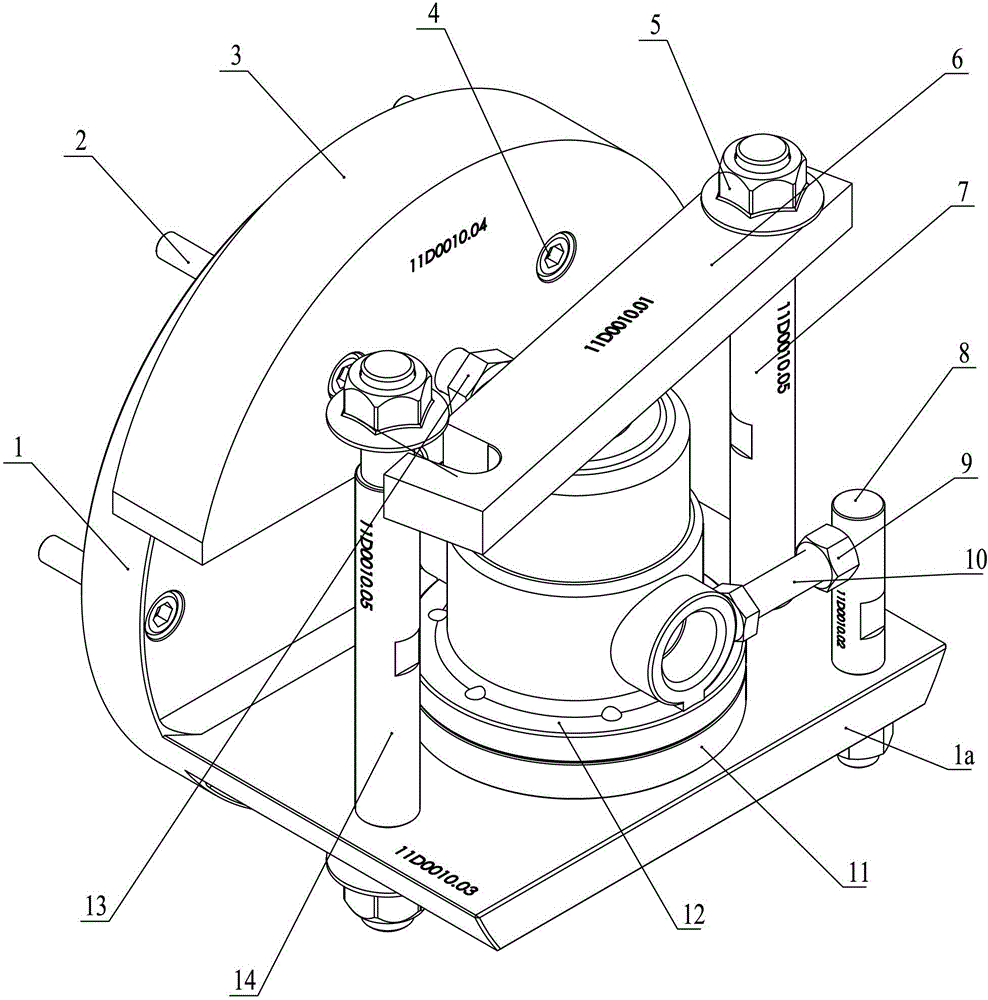

[0015] As shown in the figure: the flange-connected multi-purpose side hole processing mechanism in the embodiment is mainly composed of a flange-connected base 1, a connecting screw 2, a counterweight 3, a screw 4, a nut 5, a pressing plate 6, and a first pressing bolt 7. Screw rod 8, nut 9, positioning screw 10, positioning plate 11, parts to be processed 12, anti-vibration bolts 13 and second compression bolts 14 and other components.

[0016] Such as figure 1 As shown, the flange connection base 1 is used to connect with the rotary spindle of the CNC lathe, the lower part of the front end of the flange connection base 1 is provided with a horizontal platform 1a extending horizontally forward, and the horizontal platform 1a is provided with a positioning plate 11, The positioning plate 11 is provided with a boss for positioning the parts 12 to be processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com