Automobile brake anti-failure three-control relay valve

An automobile braking and anti-failure technology, applied in the direction of brakes, brake components, control valves and air release valves, etc., can solve the problems of non-overlapping use, vehicle damage, weak retarding braking torque, etc., and achieve easy installation. , Low loading cost, and the effect of increasing braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

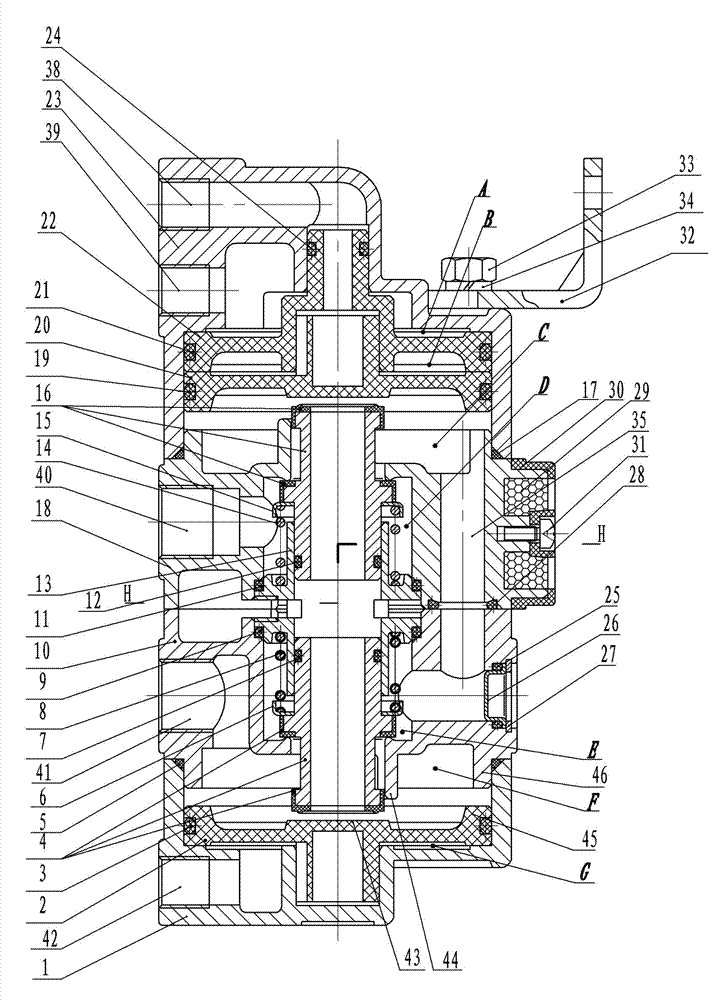

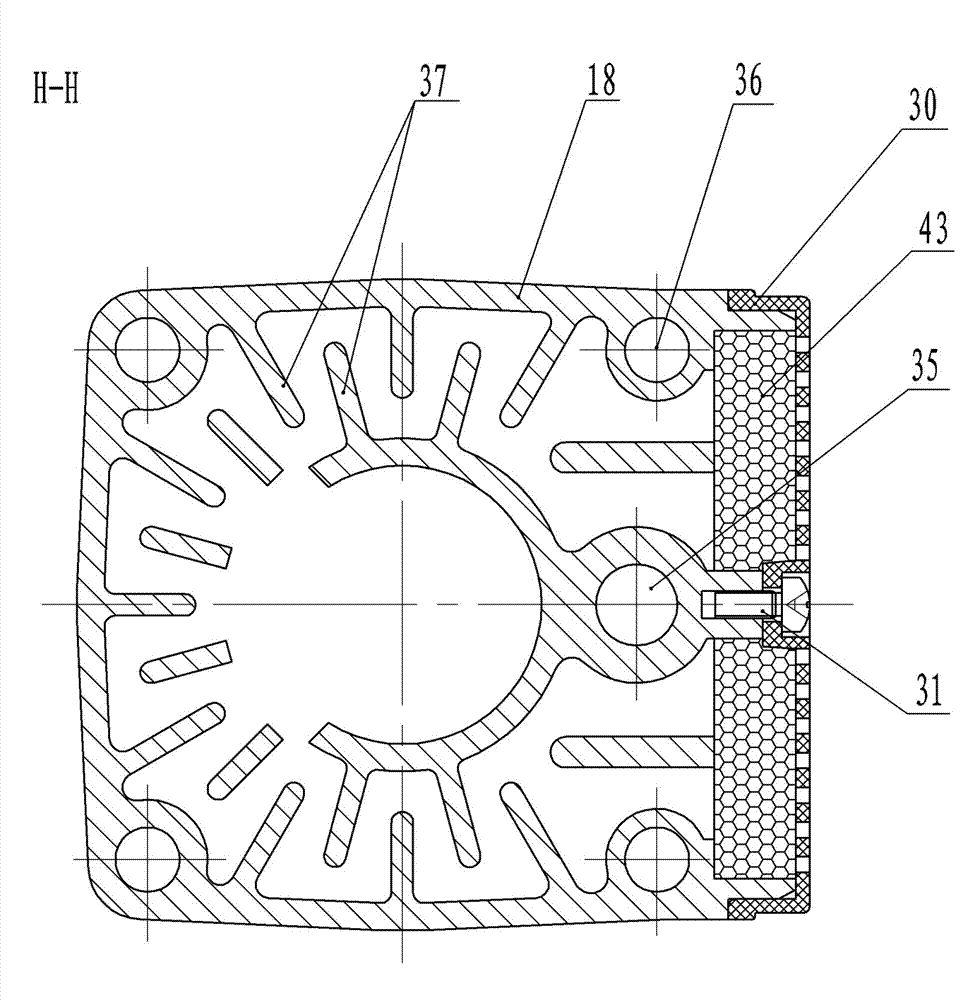

[0023] Embodiment 1: see figure 1 , The automobile brake failure prevention three-control relay valve includes an upper body 23 , a middle and upper body 18 , a middle and lower body 10 and a lower body 1 .

[0024] The upper body 23 is provided with two control air inlets, namely the control air inlet 38 and the control air inlet 39 . The inner cavity of the upper body 23 is sealed with two pistons, that is, a follower piston 20 is installed on the lower side of the upper piston 22. The upper piston 22 is a hollow structure (the piston rod is hollow), and the inner wall of the hollow cavity is provided with steps. Faced as a downward pressing surface, the center column of the follower piston 20 (the center column may be hollow but the bottom is sealed) is set under the step surface in the hollow cavity of the upper piston. The inner cavity of the upper body 23 is separated by two pistons to form a plurality of sealed and isolated air chambers. The upper side of the upper pi...

Embodiment 2

[0031] Embodiment 2, the accompanying drawings are not drawn, the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that only one upper piston is arranged in the upper body cavity, and there is no follower piston, so that the upper piston directly drives part. The center of the upper piston is provided with a plug, and the peripheral edge of the upper piston is provided with a limiting flange. The upper piston divides the upper body cavity into upper and lower air chambers, and only one control air inlet is arranged on the upper body, and the control air inlet communicates with the upper air chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com