Automobile anti-ineffectiveness brake system

A braking system and automobile braking technology, which is applied in the field of anti-failure braking systems for automobiles, and achieves the effects of superior performance, convenient operation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

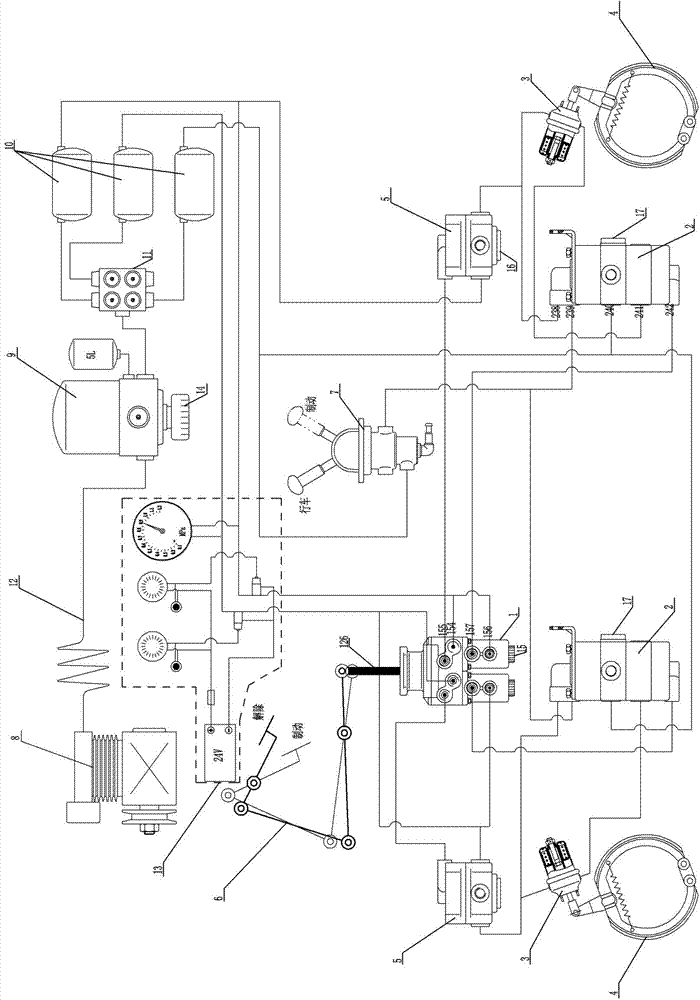

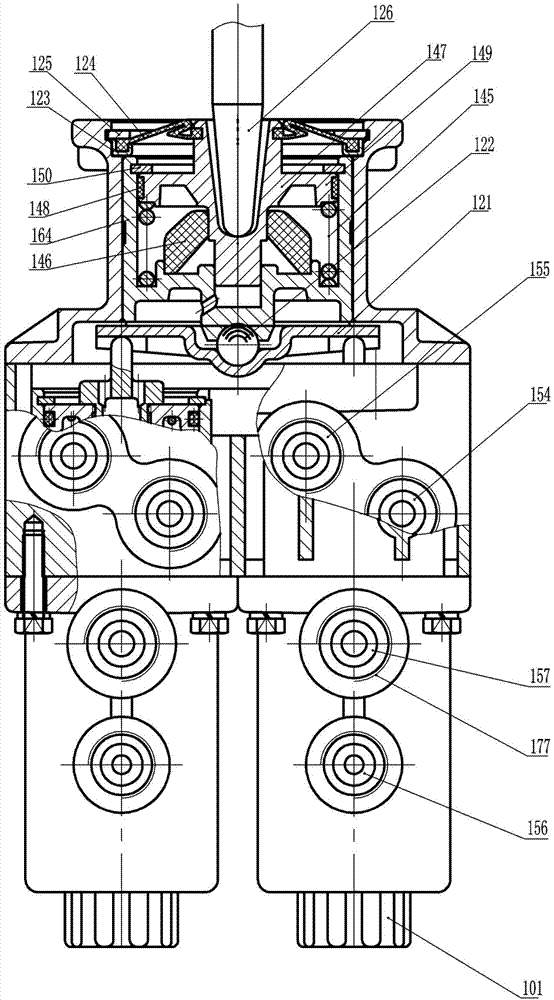

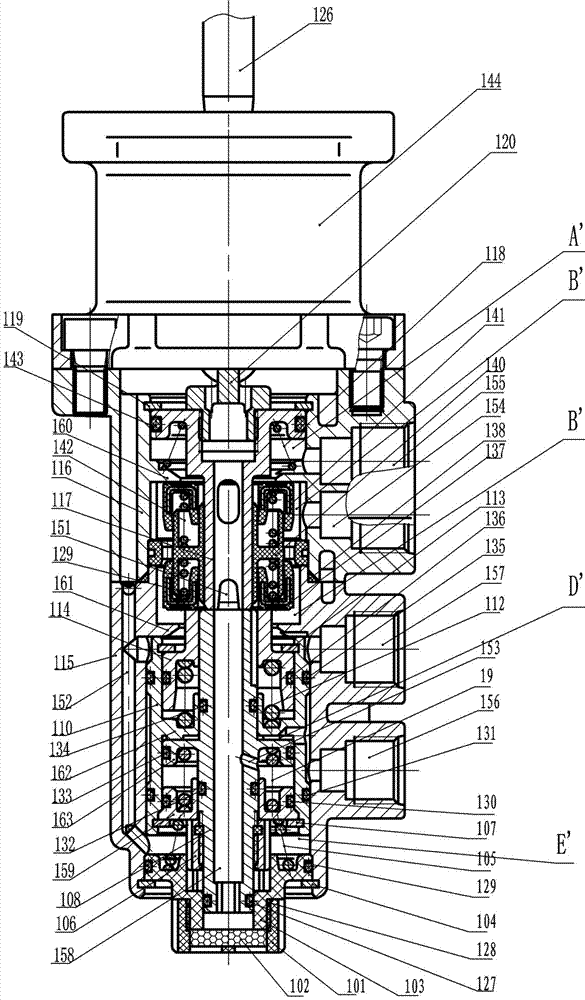

[0031] Embodiment 1: see figure 1 The anti-failure braking system of the automobile brake comprises an air compressor 8, an air filter 9, an air storage cylinder 10, an air pipe 12 and a four-circuit protection valve 11, a foot brake mechanism 6 and a hand brake mechanism 7, a relay valve 8, and The spring energy storage air chamber 4, the front axle and the rear axle brake 3, and the air circuit of the braking system also include an air pressure monitoring and alarm device 13 and the like. Wherein, on the ejector rod 126 of foot brake mechanism 6, anti-failure brake main valve 1 is installed, and anti-failure brake main valve 1 is provided with air inlet 154, air outlet 155, control air inlet 156 and control air outlet 157; the air inlet 154 communicates with the gas cylinder 10 through the air pipe, and the air outlet 155 communicates with the control port of the relay valve 8 through the air pipe, and the air inlet of the relay valve 8 communicates with the gas cylinder 10...

Embodiment 2

[0052] Embodiment 2: The content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the lower end of the valve seat is directly in contact with a thimble, and only one set of braking system is used.

Embodiment 3

[0053] Embodiment 3: The content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that only one upper piston is arranged in the upper body cavity, and there is no follower piston, so the upper piston is directly a driving component. The center of the upper piston is provided with a plug, and the peripheral edge of the upper piston is provided with a limiting flange. The upper piston divides the upper body cavity into upper and lower air chambers, and only one control air inlet is arranged on the upper body, and the control air inlet communicates with the upper air chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com