Block duoble-directional overrunning clutch parking brake and manufacturing method thereof

A clutch type and wedge technology, applied in one-way clutches, drum brakes, brakes, etc., can solve the problems of large size and weight, small braking torque, etc., and achieve the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

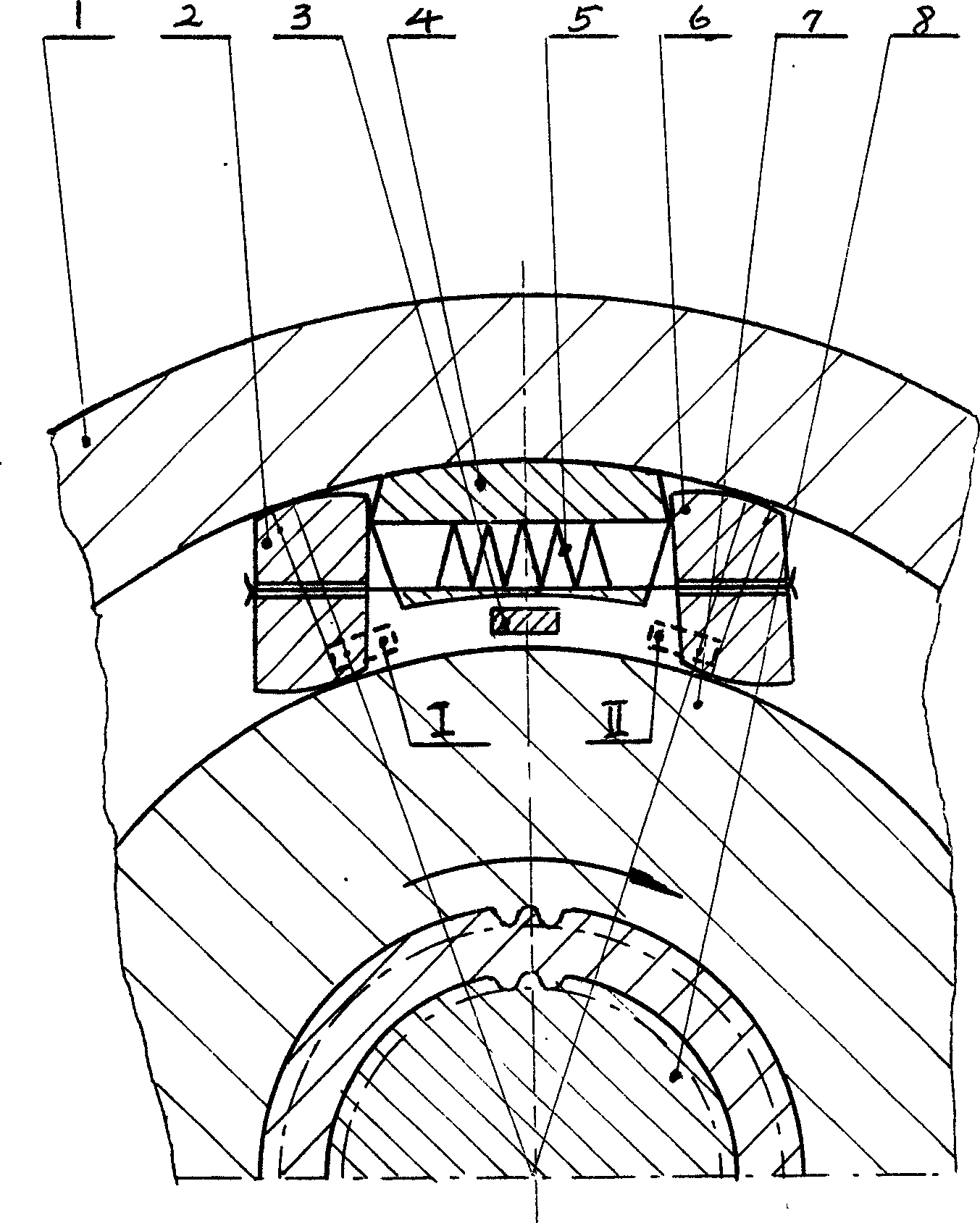

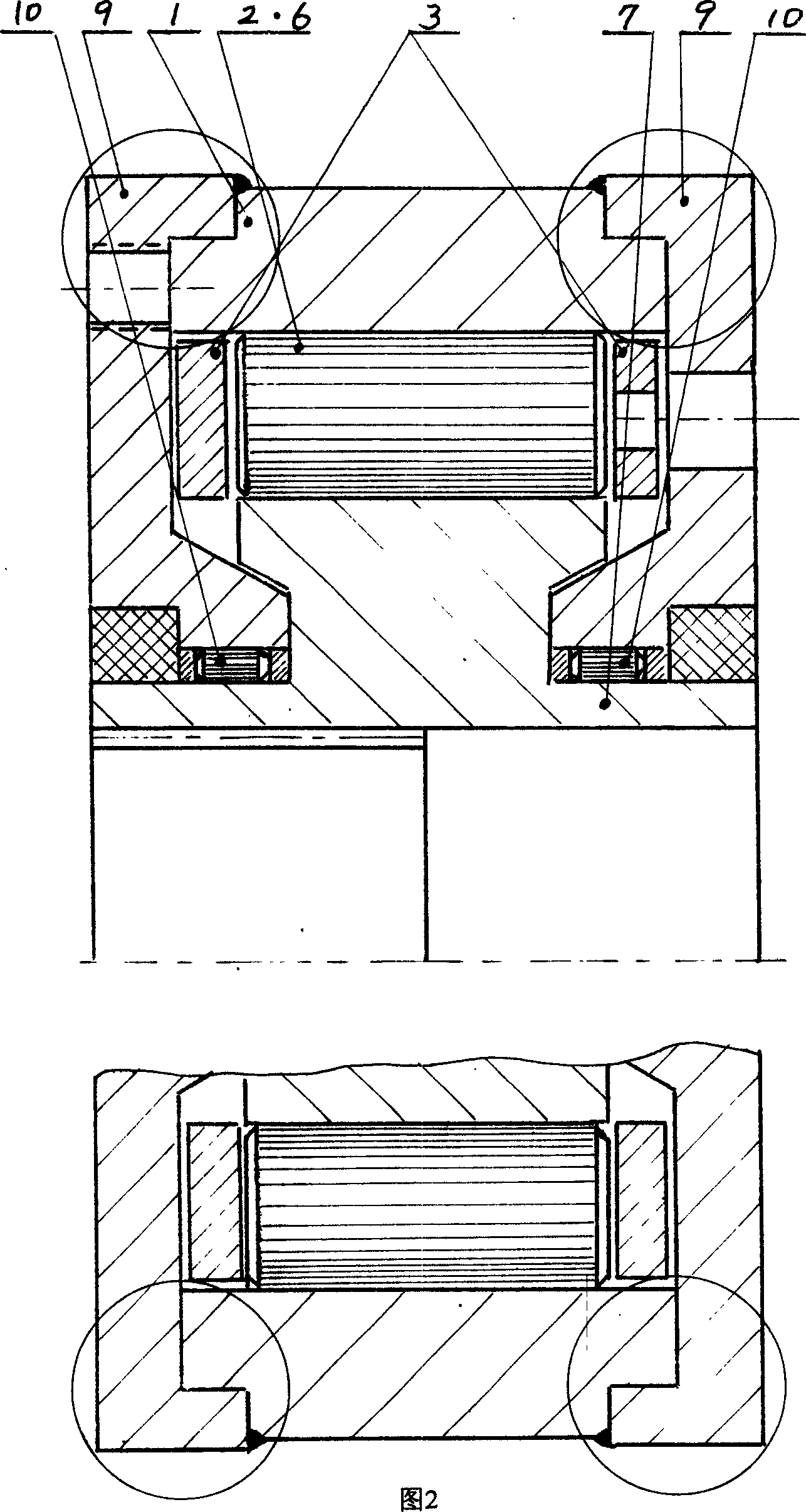

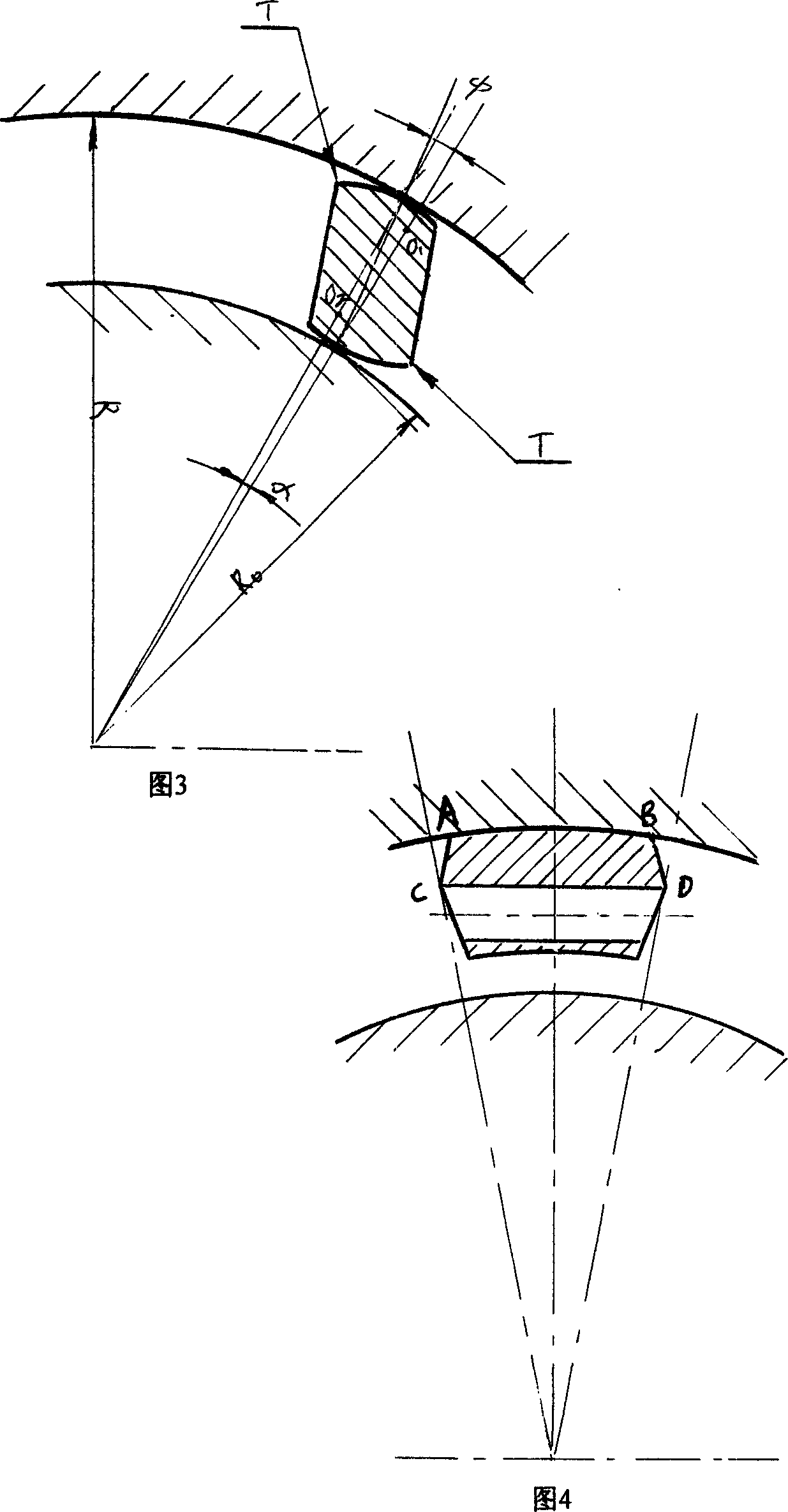

[0012] figure 1 Among them, the outer ring (1) is fixed on the rear wall of the transmission housing, and a spring seat (4) and a spring (5) are housed inside it. The inner ring (7) is splined with the second shaft of the transmission through a splined shaft (8). The direction indicated by the arrow is the direction of rotation of the transmission shaft, that is, the inner ring (7) when the automobile advances. A shift fork (3) and two groups of wedges (2) and (6) are arranged between the outer ring (1) and the inner ring (7). The small angle rotation of wedge (2) and (6) is controlled by the pulling force of spring (5), frictional force and shift fork (3). figure 1 It is not difficult to see that when the inner ring (7) rotates in the direction indicated by the arrow, that is to say when the car is moving forward [the effect of the wedge (6) is not considered at this time, only the wedge (2) is considered] if the fork (3) If the wedge (2) is not controlled, the wedge (2) w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com