Silk winding machine

A technology of winding machine and wire pressing is applied in the fields of winding equipment, yarn winding and winding machine, which can solve the problems of fast thread passing speed, easy thread breakage, narrow application range and high thread breakage rate, and achieves the structure Simple, wide application range, low disconnection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

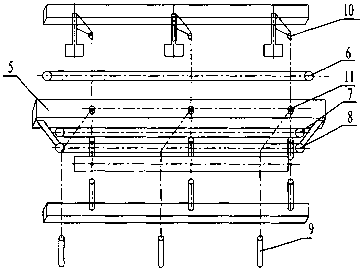

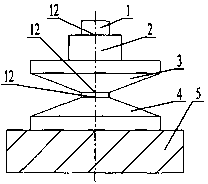

[0014] Such as Figure 1 to Figure 2 As shown, a wire winding machine includes a frame 5 and a thread pressing device 11 , and also includes a first guide rod 6 and a second guide rod 7 . The wire-passing wire pressing device 11 is composed of a guide shaft 1, a pressing block 2, an upper pressing wire sheet 3 and a lower pressing wire sheet 4, and the middle parts of the pressing block 2, the upper pressing wire sheet 3 and the lower pressing wire sheet 4 all have The mounting hole 12, the pressing block 2, the upper thread pressing sheet 3 and the lower thread pressing sheet 4 are set on the guide shaft 1 sequentially through the mounting hole 12 from top to bottom. The lower part of the guide shaft 1 of the thread pressing device 11 is fixedly arranged on the frame 5 . The first guide rod 6 and the second guide rod 7 are fixedly arranged on the frame 5, and the two ends of the first guide rod 6 are connected with the side of the frame 5, and the two ends of the second guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com