Spiral-arm hydraulic push-rod decanting device

A hydraulic push rod and decanter technology, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems that cannot meet the process needs, require regular maintenance, and high wear rate , achieve the effect of saving frequency converter hardware, reducing equipment cost and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the following will be described in detail with reference to the embodiments and accompanying drawings.

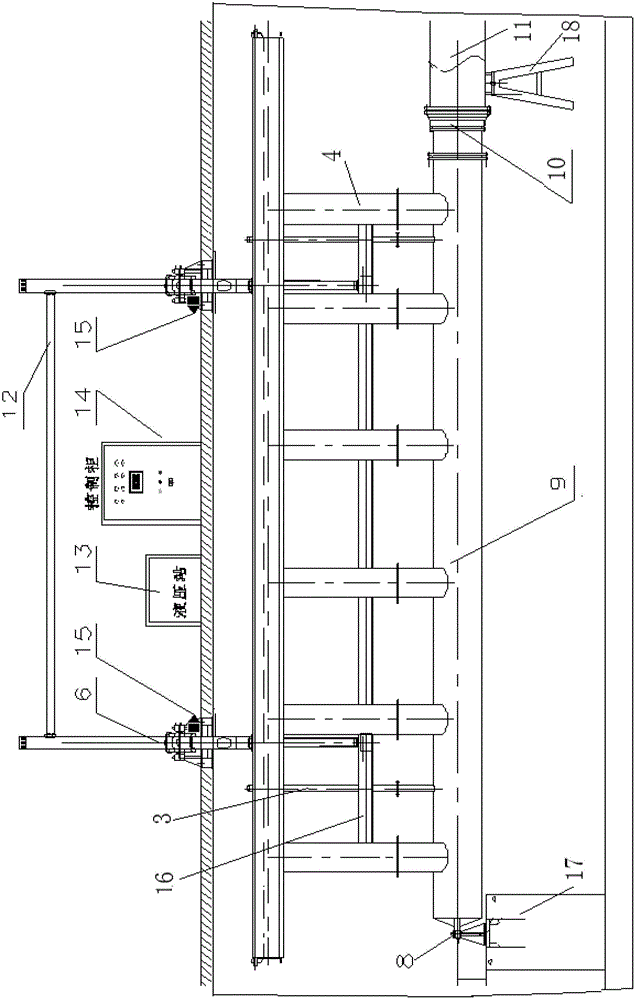

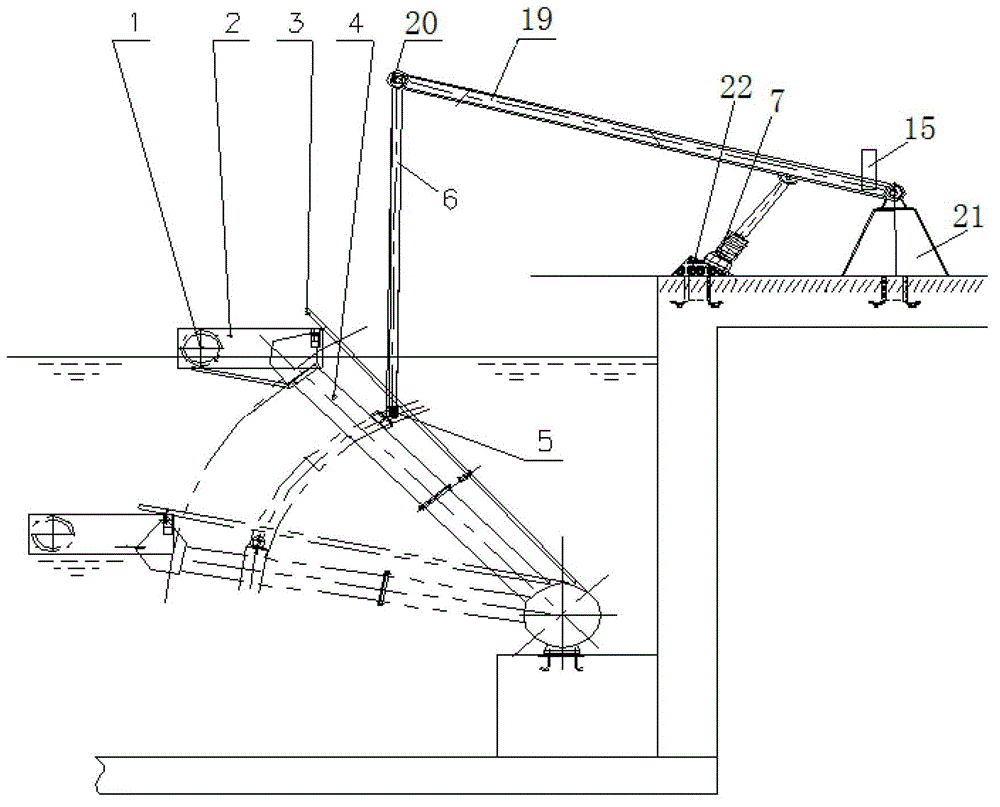

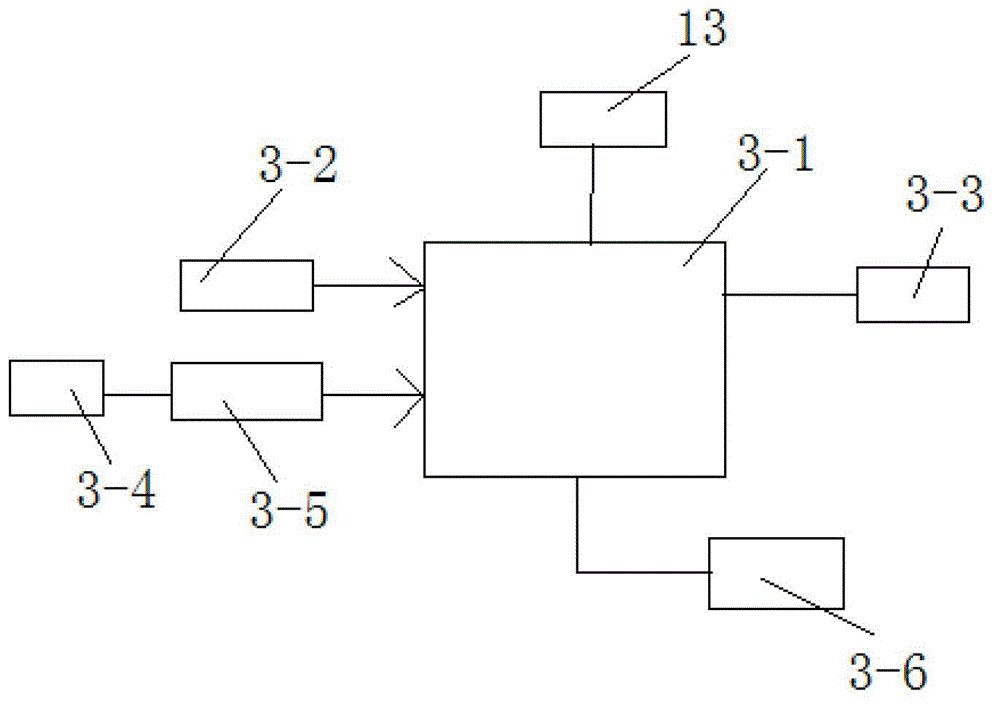

[0023] Such as figure 1 , 2 As shown in , 3, a swing arm type hydraulic push rod decanter includes 1 buoy, 2 weir grooves, 3 air outlet pipes, 4 water outlet pipes, 5 joints, 6 rods, 7 hydraulic push rods, 8 Bearing, 9 water outlet main pipe, 10 pipe bearing, 11 drain pipe, 12 hanger connecting rod, 13 small hydraulic station, 14 control cabinet, 15 angular displacement measurement and transmission system, 16 connecting rod, 17 support one, 18 support two , 19 poles two, 20 live joints two, 21 hanger base, 22 hydraulic push rod base.

[0024] Rotary arm hydraulic push rod decanter, including buoy 1, weir tank 2, water outlet main pipe 9, hydraulic power unit, hydraulic integrated control system, buoy 1 and weir tank 2 are connected as one, and weir ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com