Method for dynamically preparing RexCe1-xOy buffer layer long belt by using chemical solution

A technology of chemical solution and buffer layer, applied in the field of high temperature superconducting tape preparation, can solve the problems of high manufacturing cost, large-scale application of high temperature superconducting tape, unfavorable development of tape industrialization, low film production efficiency, etc. Critical thickness, low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

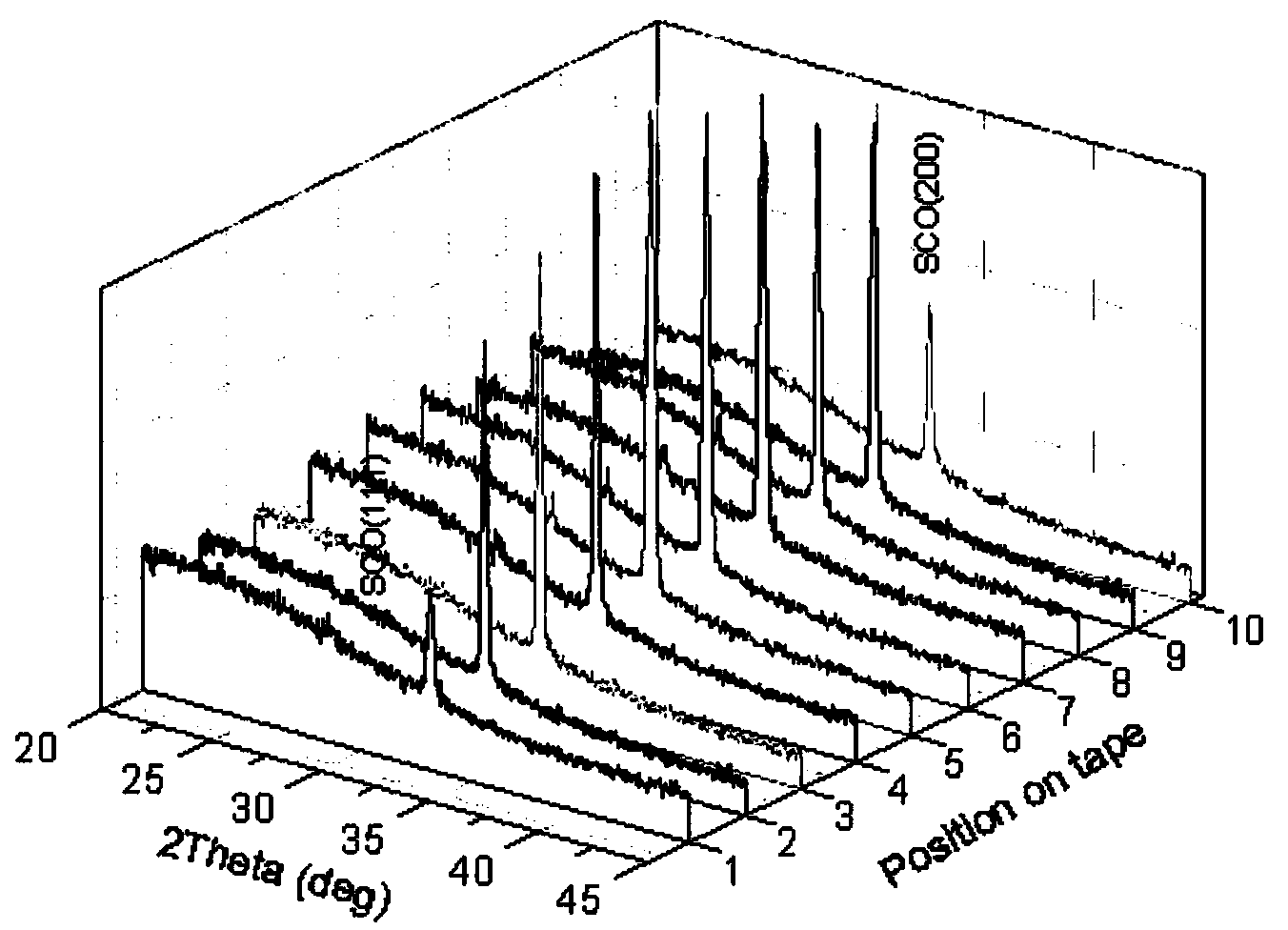

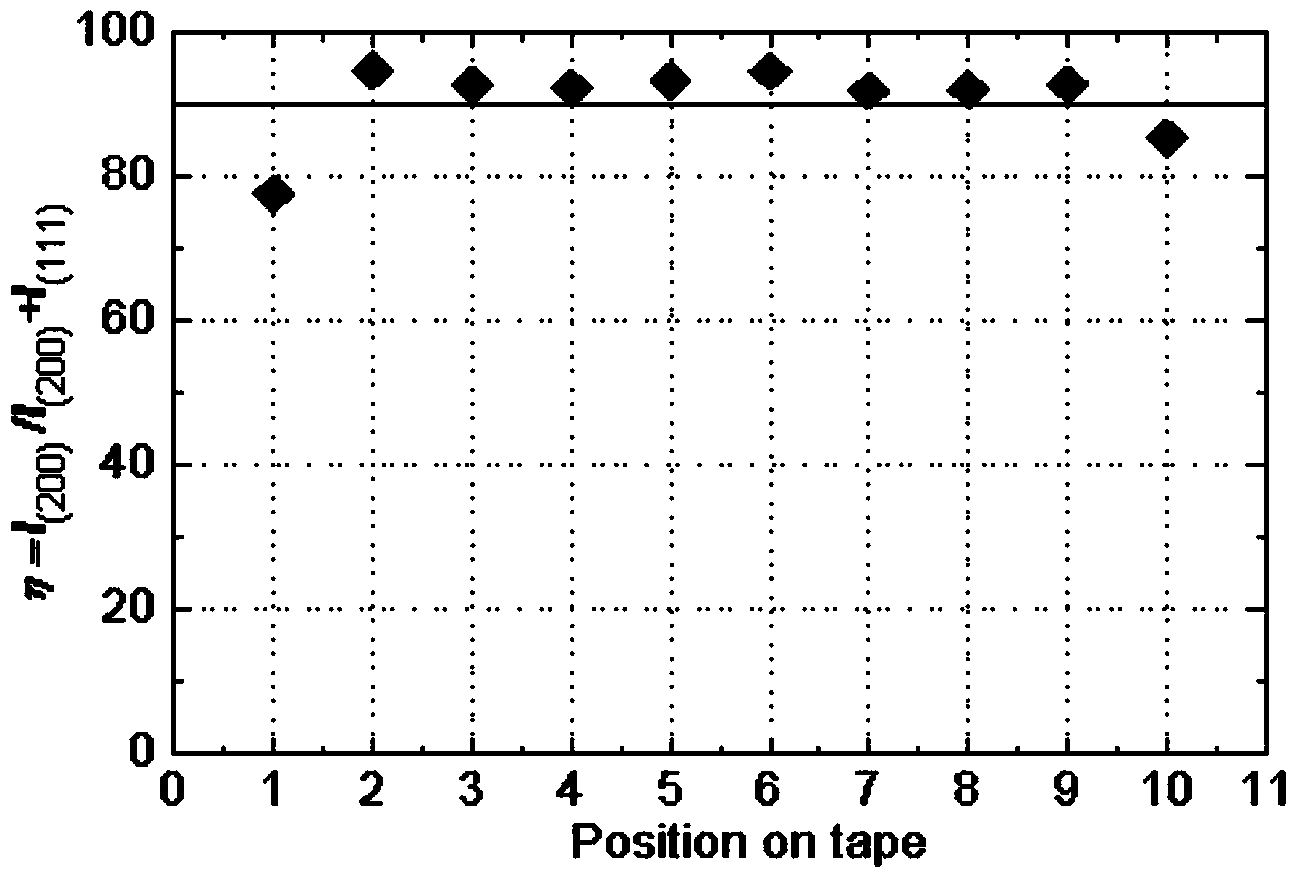

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] The invention provides a chemical solution for dynamically preparing Re x Ce 1-x o y The method of buffer layer long band, its concrete practice is:

[0026] a wet film preparation:

[0027] A nitrate mixture was prepared at a ratio of 0.2:0.8 for Sm ions and Ce ions, and was dissolved in 15 wt.% polyacrylic acid and N-N dimethylformamide polymer to obtain a colloid. Put the colloid into the liquid storage cylinder, place the 110 cm long Ni-5%W base belt on the traction belt, and drive it forward by the stepping motor at a speed of 0.20 m / h, and the colloid is also driven by the upper stepping motor at 0.5 mL Under the rotation speed of / h, the pressure is driven down and coated on the base belt through the slit coating port to form a wet film.

[0028] b Preparation of dry film:

[0029] Pass the coated wet film through 120 at a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com