Polymer microsphere preparation method and polymer microsphere application

A technology of polymer microspheres and base spheres, which is applied in the direction of ion exchange, ion exchange regeneration, ion exchange treatment devices, etc., can solve the problems of weak retention capacity, unsuitable for large-scale preparation and separation of fullerenes, etc., to achieve easy reaction, particle size The effect of large diameter and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

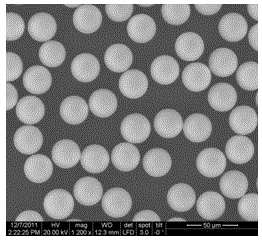

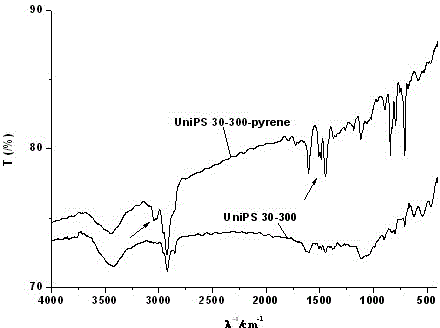

[0021] According to the technical scheme disclosed in Chinese invention patent CN101186661, polystyrene microspheres are prepared, which are recorded as UniPS 30-300. Weigh 40.00 g of polystyrene microspheres (UniPS 30-300 microspheres, about 30 μm in diameter) as the base ball in a dry three-neck flask, add 300 mL of dichloromethane solvent, and stir the microspheres evenly , then add 11.41 g SnCl with a syringe 4 in the suspension above. During the reaction process of the three-necked bottle, attention should be paid to airtightness, and the sealing ring and pipes that contact the reaction solution and steam should be corrosion-resistant. The temperature was slowly raised to 50°C to ensure a stable reaction, and the reaction was carried out overnight. After the reaction is completed, the reaction suspension solution is lowered to room temperature. The suspension was filtered with a sand core funnel, and the microspheres were washed with acetone, ethanol, dilute hydrochlor...

Embodiment 2

[0028] The reaction apparatus is the same as in Example 1. In a dry 250 mL three-neck flask, 10.00 g of polystyrene UniPS 30-300 microspheres prepared according to the technical scheme disclosed in Chinese invention patent CN101186661 were weighed in advance. First add 75 mL of chloroform solvent into the three-necked flask, and stir the microspheres evenly. Finally, with the addition of 2.23 g of SnCl 4 in the suspension above. Reaction control and ball washing steps are the same as in Example 1.

[0029] Mix 10.8 g of chloromethylated microspheres obtained above with 4.00 g of coronene, add 75 mL of chloroform solvent into a three-neck flask, and stir the microspheres evenly. Finally, add 2.23 g SnCl 4 in the suspension above. Reaction control and ball washing steps are the same as in Example 1. 11.9 g of permeate-functionalized polymer microspheres can be obtained.

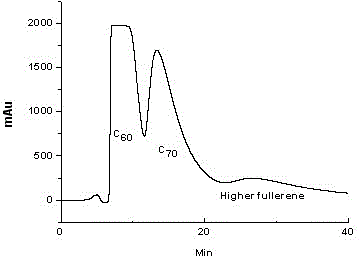

[0030] The polymer microspheres prepared in the present invention contain fused-ring aromatic hydroca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com