Metal sound insulation low-frequency acoustical board

A sound-absorbing panel and sound-insulating technology, applied in the direction of sound insulation, building components, etc., can solve the problems of difficult to grasp the sound-absorbing frequency range, not belonging to the resonance sound-absorbing structure, unable to achieve the sound-absorbing effect, etc. Maximum, sound absorption frequency reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

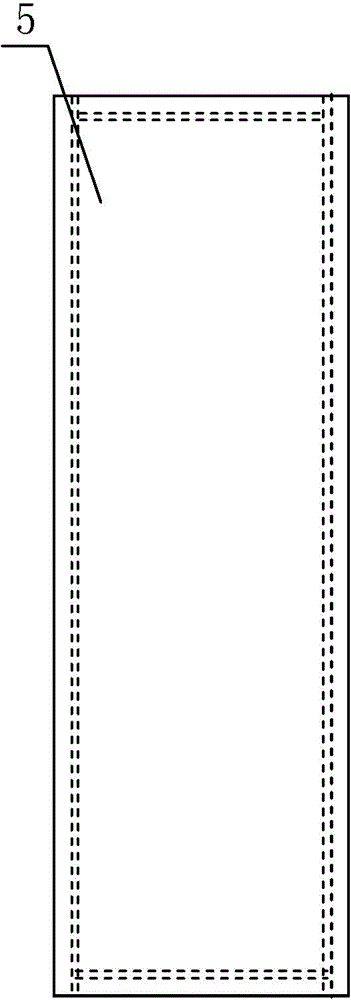

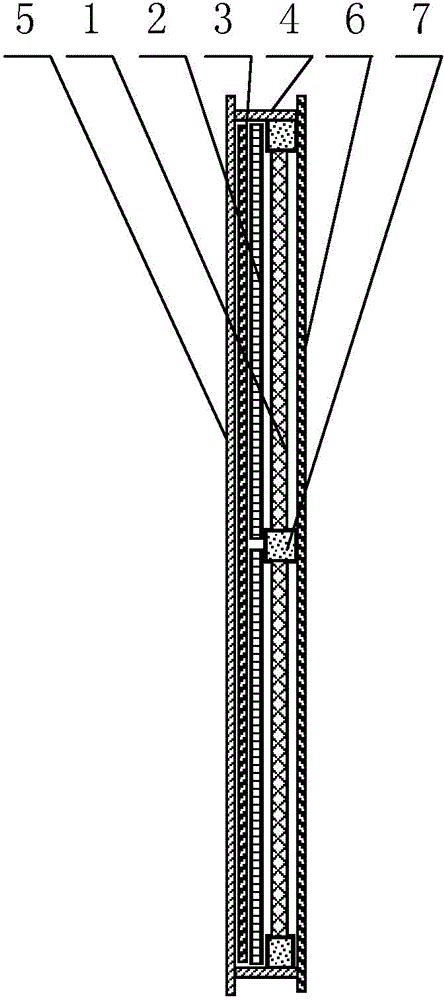

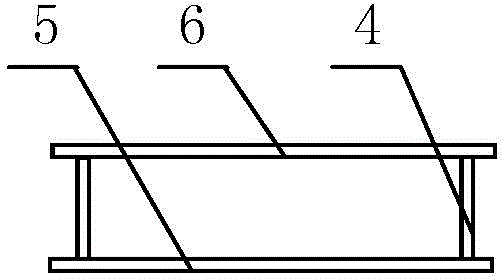

[0028] like figure 1 , figure 2 , image 3 As shown, a metal sound-insulating low-frequency sound-absorbing panel includes a shell made of bent steel plates, an elastic material 1, a resonant plate 2, and an elastic pad 3. The housing is a flat module with a size of 1*3*0.1m (width*height*thickness). The groove shape of the opening is convenient for filling glass wool sound-absorbing material inside when connecting adjacent modules, and then connecting and fixing with H-shaped connectors to improve its sound insulation and sealing effect. A layer of outer surface steel plate 6 is installed on the frame 4. The purpose is to improve the sound insulation of the module while making its outer surface firm and easy to assemble into a pentahedral room. The elastic material 1 and the resonant plate 2 are installed in the housing, wherein the elastic material can be glass wool, open-pore sponge, soft fiberboard and porous sound-absorbing material, and open-pore sponge is selected i...

Embodiment 2

[0032] The shape of the periphery of the frame 4 is a Z shape that extends outwards. It can be extended outwards on the upper and lower sides or on the left and right sides, or Z-shaped connectors can be installed to fix the module on the building wall. According to the needs of noise reduction frequency, the existing room Low-frequency sound absorption inside. Other structures of the module are the same as those in Embodiment 1.

Embodiment 3

[0034] The resonance plate 2 is a steel plate or an aluminum plate, and the thickness of the steel plate or the aluminum plate is 0.7-3mm. This embodiment is an 8mm galvanized steel plate. Since the steel plate is heavy, the resonance frequency of the thin plate resonant structure can be reduced. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com