Device and method for preparing hydrogen and oxygen by utilizing waste heat of tail gas to perform temperature difference generation

A technology of thermoelectric power generation and exhaust gas, which is applied to exhaust devices, mufflers, generators/motors, etc., can solve the problems of consumption of hydrogen and oxygen generators, difficulty in storage and transportation on-board, and difficulty in utilizing the heat of exhaust gas from internal combustion engines with battery power. The effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Present embodiment has carried out following experiment on the 1.8L Elantra car produced by Beijing Hyundai:

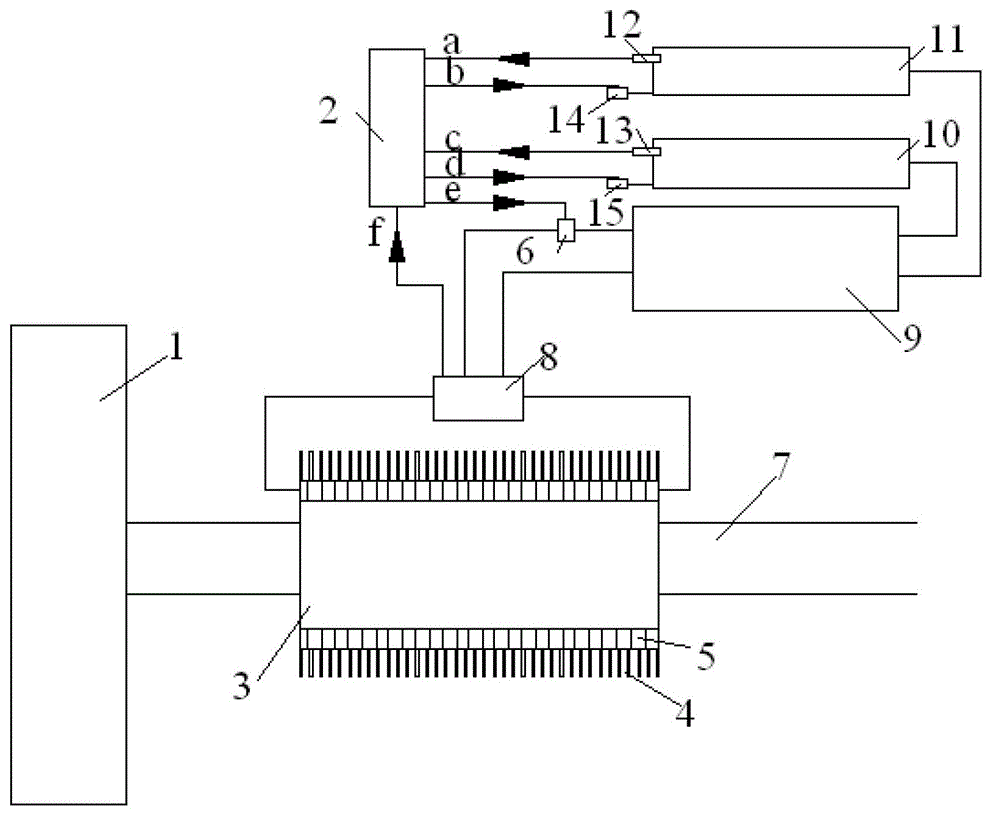

[0020] Before the experiment according to figure 1 The structure shown is to build a device that utilizes the waste heat of the exhaust gas of the internal combustion engine to generate gas by temperature difference. The box 3 is installed on the original exhaust pipe 7 of the internal combustion engine 1 through the flange, so that the exhaust gas can directly enter the box 3 and generate electricity for the temperature difference. Group 5 provides a high-temperature heat source, installs the heat sink group 4 on the thermoelectric power generation unit 5, uses the heat sink group 4 to cool down the other end of the thermoelectric power generation group 5 and provides a low-temperature heat source, hydrogen and oxygen generator 9, hydrogen tank 10, and oxygen tank 11. The electronic control unit 2, relay 6 and voltage regulator 8 are all arranged in the trunk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com