Cold-hot water mixing valve body with upper water outlet passage and lower water outlet passage

A water outlet channel and water mixing valve technology, applied in valve details, valve device, valve shell structure, etc., can solve the problems of increasing thermal joints and material consumption, reducing the reliability of valve body use, shrinking cracks and water leakage, etc. Effects of weight and production costs, reduced thermal joints and material consumption, reduced likelihood of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

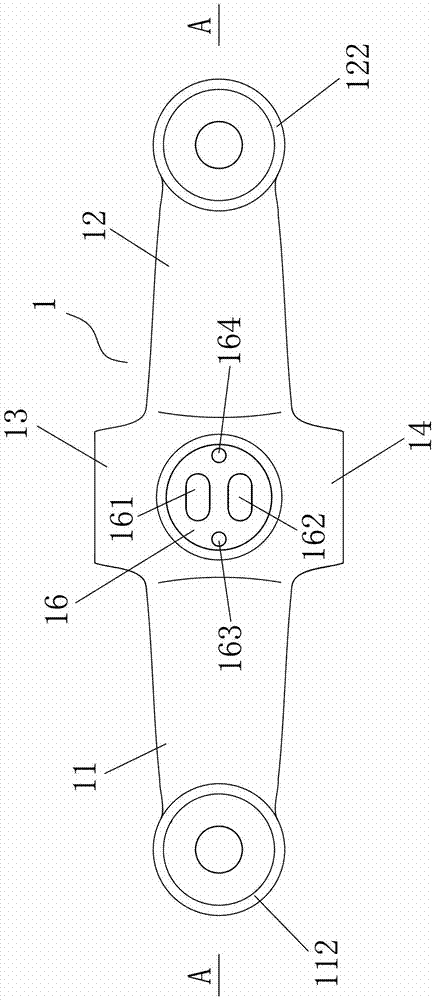

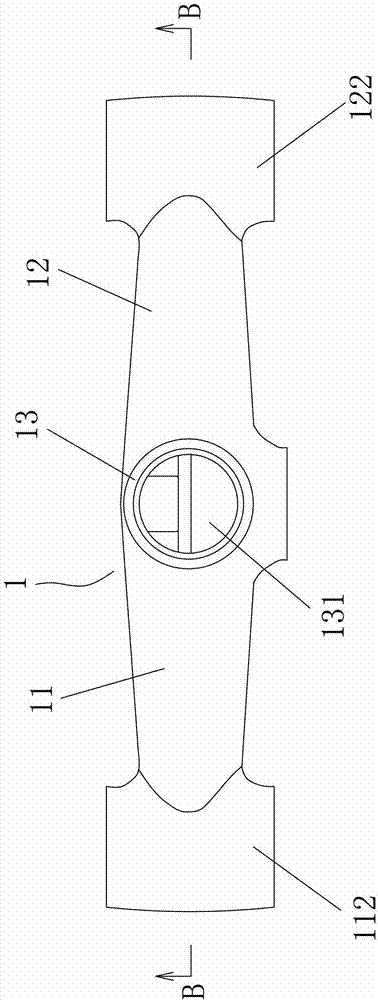

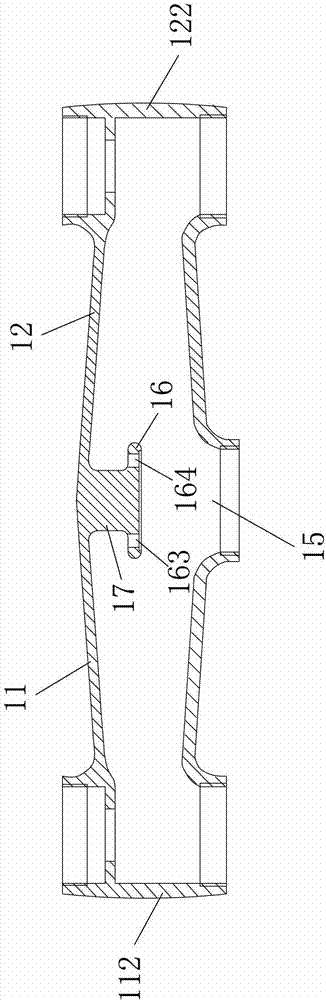

[0017] Figure 1 to Figure 4 As shown, a cold and hot water mixing valve body with upper and lower water outlet channels includes a generally cross-shaped valve housing 1, and the middle of the left arm 11 and right arm 12 of the valve housing 1 is provided with water inlet channels 111, 121, The middle of the upper arm 13 and the lower arm 14 of the valve casing 1 is provided with water outlet passages 131, 141, the joints of the left and right arms 11, 12 and the upper and lower arms 13, 14 are provided with a spool installation passage 15, and the middle of the left arm and the right arm The water inlet channels 111 and 121 are connected through the valve core installation channel 15, the bottom of the valve core installation channel 15 is provided with a valve core positioning partition 16, and a rear partition is connected betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com