Finite difference method of fine simulation tubular well structure

A finite-difference, simulated tube technology, applied in complex mathematical operations, etc., can solve problems such as difficulty in achieving test results for test wells, differences in well-forming techniques, etc., and achieve fast and practical calculation methods and low-cost effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: The method of the present invention is illustrated below with the filter pipe being located in the complete well of the confined aquifer as an example, wherein the opening mode of the filter pipe is arranged in a circular character shape, and the opening rate is assumed to be 25%. For simplicity, it is assumed that the surface elevation is 0m, and the formation There are four layers in total, from top to bottom:

[0025] Layer: phreatic aquifer with a thickness of 5m and a water head of -2m;

[0026] Layer: waterproof layer, thickness 3m, water head -2m;

[0027] Layer: Confined aquifer, 10m thick, -2m water head, the layer where the filter tube is located;

[0028] layer; a water-resistant layer with a thickness of 2m and a water head of -2m.

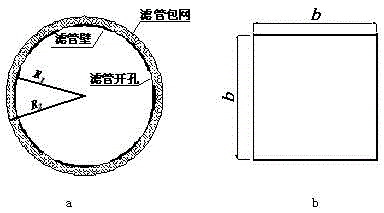

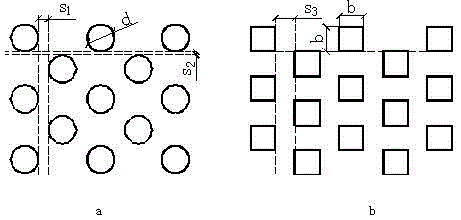

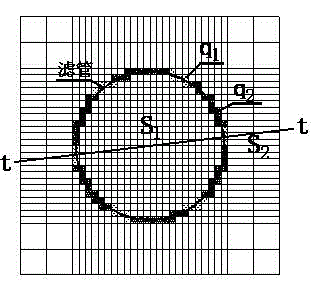

[0029] 1, figure 1 It is the equivalent diagram of the filter tube. Figure a is the opening layout of the filter tube before the equivalent. The round holes are distributed in the shape of a square, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com