Design method of blade power-increasing trailing edge flap

A design method and flap technology, applied in design optimization/simulation, mechanical equipment, and wind turbines consistent with the wind direction, etc., can solve problems such as lack of flap design methods, achieve reduced induced drag loss, high accuracy, The effect of increasing the ability to capture wind energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

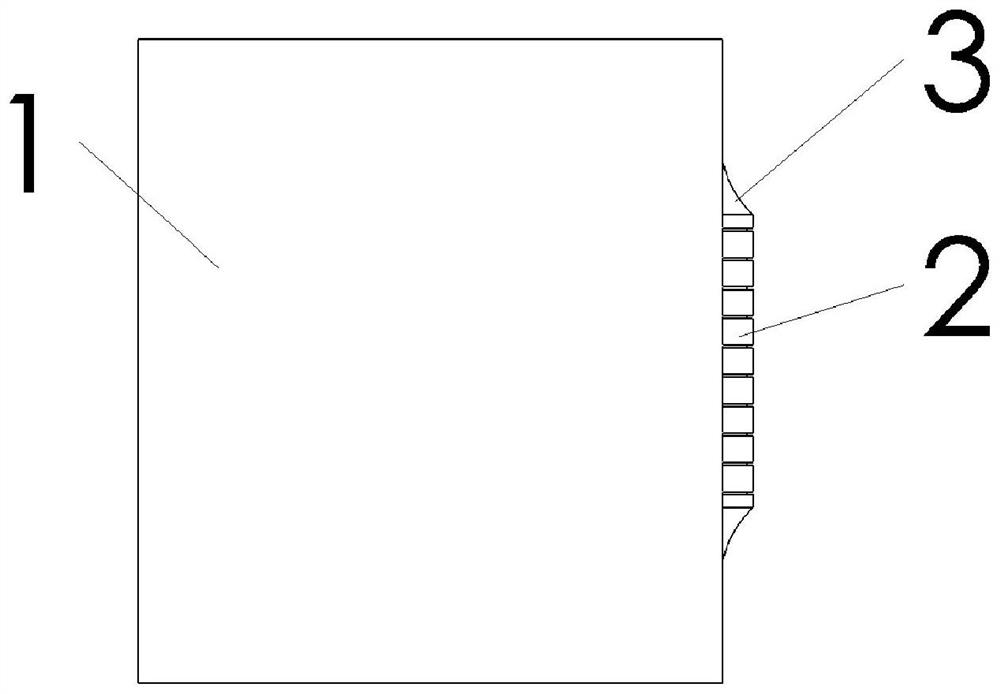

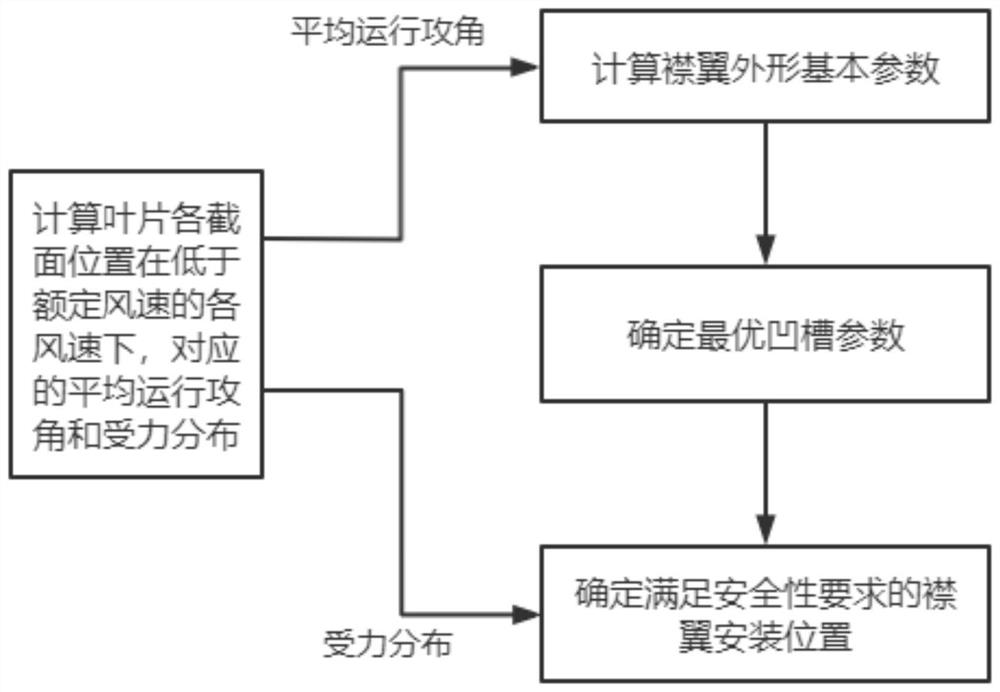

[0056] Such as image 3 As shown, a blade power-enhancing trailing edge flap design method, the steps include:

[0057] Step 1: Calculate the corresponding average operating angle of attack and force distribution of each cross-section position of the blade at each wind speed lower than the rated wind speed;

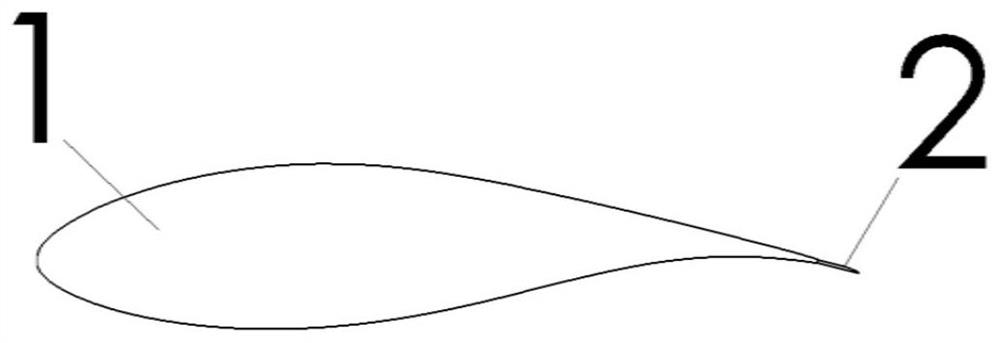

[0058] Step: 2: Design and calculate the flap profile and parameters by the average operating angle of attack;

[0059] Step 3: Calculate the optimal groove parameters through the shape and parameters of the flap;

[0060]Step 4: Determine the flap installation position that meets the safety requirements through the optimal groove parameters and the force distribution in step 1.

[0061] Specific steps such as Figure 4 shown.

[0062] Described step 1 comprises as follows:

[0063] The average operating angle of attack and force distribution corresponding to each section position of the blade at each wind speed lower than the rated wind speed are calculated by GH Bl...

Embodiment 2

[0096] Taking the NACA63421 airfoil as an example, the external dimensions of the flap and the groove are designed and calculated according to the content of the present invention. The lift calculation results of different shapes of Rfoil are as follows: Figure 6 As shown, in the figure Mach=0.15, Re=3E6. The calculations of flap down angle, thickness, and wedge shape are the same as in Embodiment 1. The lift-to-drag ratio of the airfoil varies with the flap length as follows: Figure 7 shown.

[0097]

[0098]

[0099]

[0100] Model the determined flap dimensions and NACA63421 airfoil structure in 3D modeling software, design the surface groove size, and perform grid division, steady-state calculation and transient calculation iterations through professional fluid calculation software, and get Optimal groove parameters and aerodynamic effects.

[0101] The final calculation results show that after the NACA63421 airfoil is equipped with flaps with grooves, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com