Method for simulating solid combustion process based on thermodynamic model

A thermodynamic model and combustion process technology, applied in 3D modeling, image data processing, instruments, etc., to achieve the effect of improving the performance of details and high computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

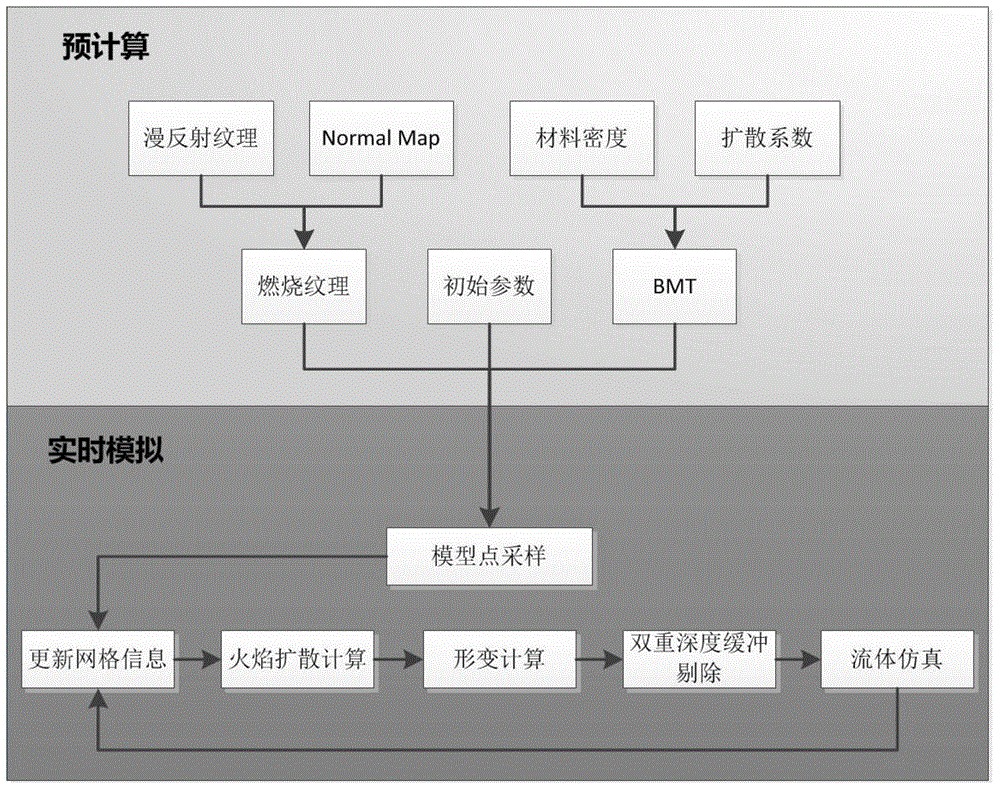

[0027] figure 1 The overall processing flow of the solid combustion process based on the thermodynamic model is given, and the present invention will be further described below in conjunction with other drawings and specific embodiments.

[0028] The invention provides a method for simulating a solid combustion process based on a thermodynamic model. The main steps are as follows:

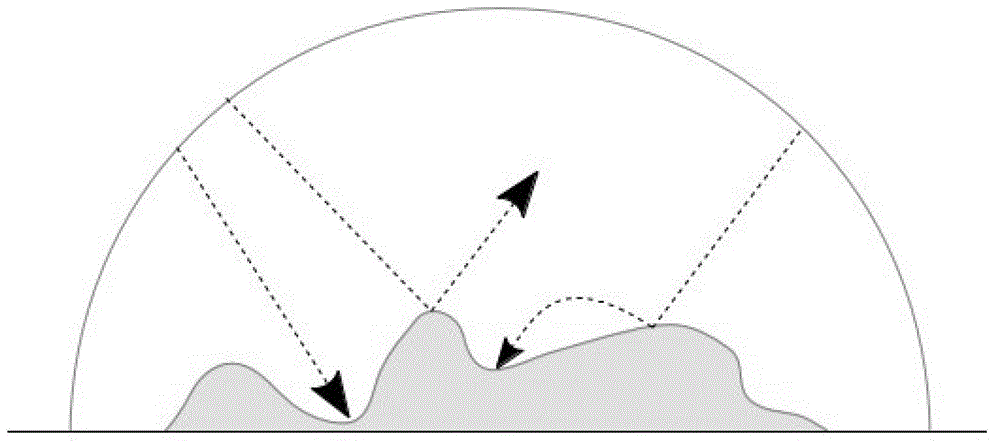

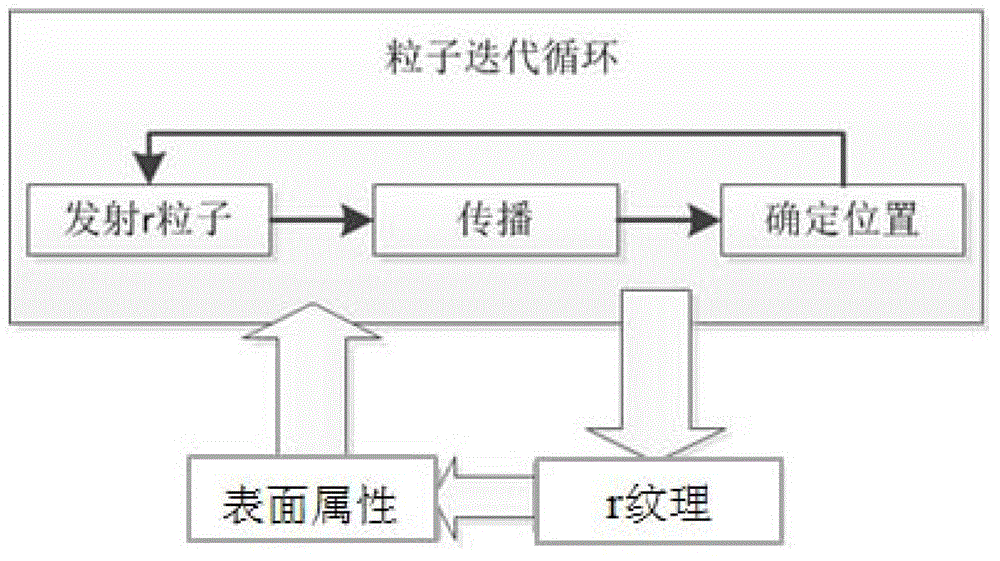

[0029] 1. Burning diffuse reflection texture precomputation method

[0030] This method combines precomputation and procedural texture (Procedural Texture) to simulate the special effect of the surface of the object when the flame burns. When the solid is burned, the small undulations on the surface of the model will cause some detailed changes in the surface color, such as: cracks, color differences caused by undulations, and so on. Taking charcoal as an example, the burning process of charcoal has complex and rich details. The part of the charcoal that is burning will turn red, the part that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com