Zero-sequence current transformer and manufacturing method thereof

A current transformer and zero-sequence current technology, applied in the field of zero-sequence current transformer and its production, can solve the problems of manufacturing process differences, poor balance characteristics of zero-sequence current transformer, residual current action protector misoperation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

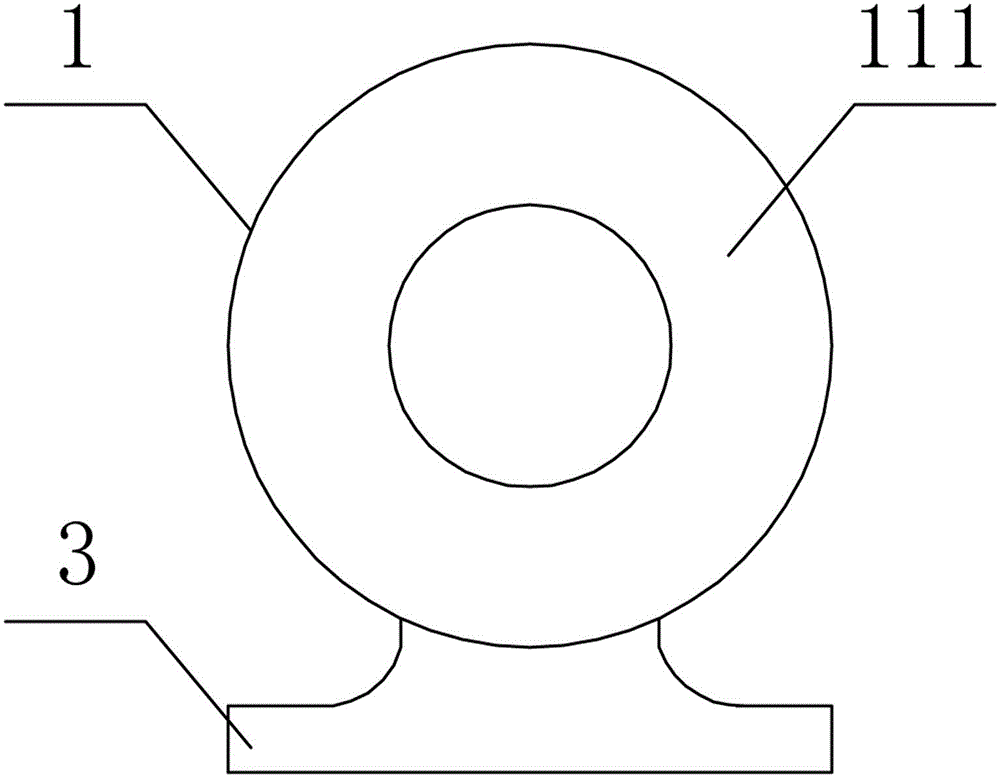

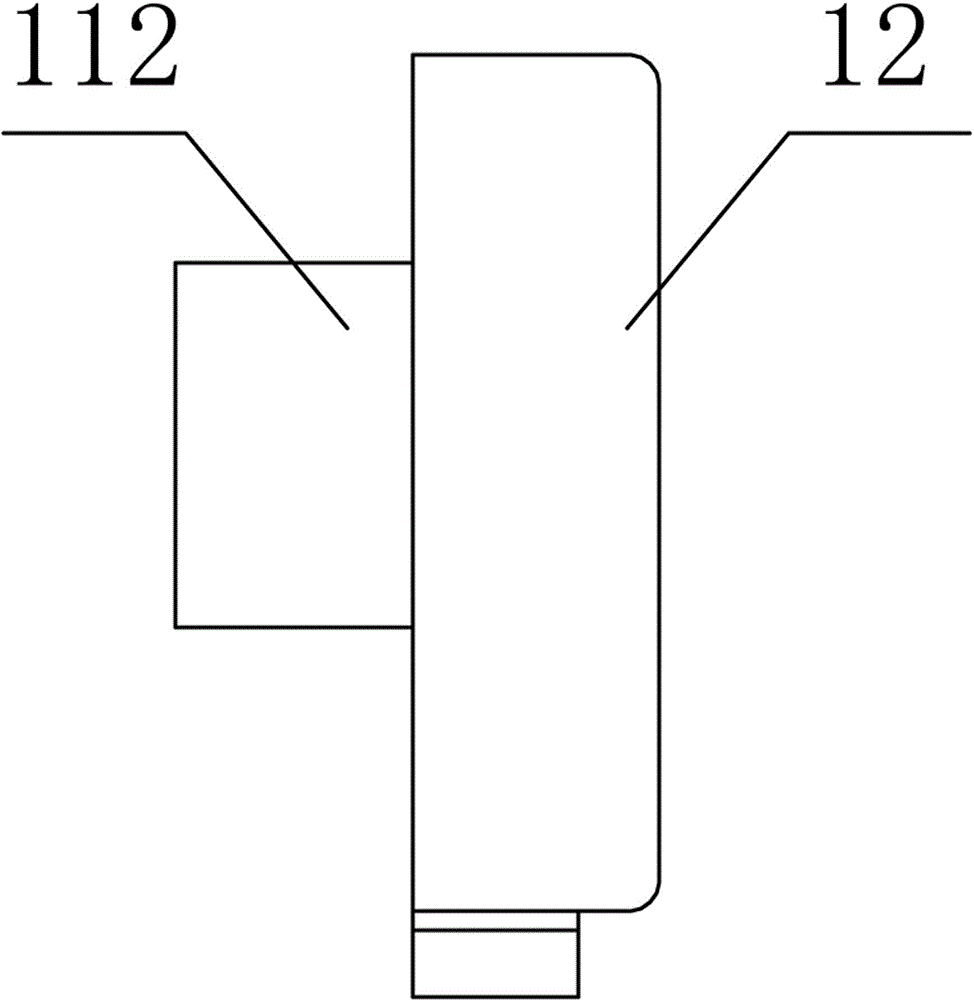

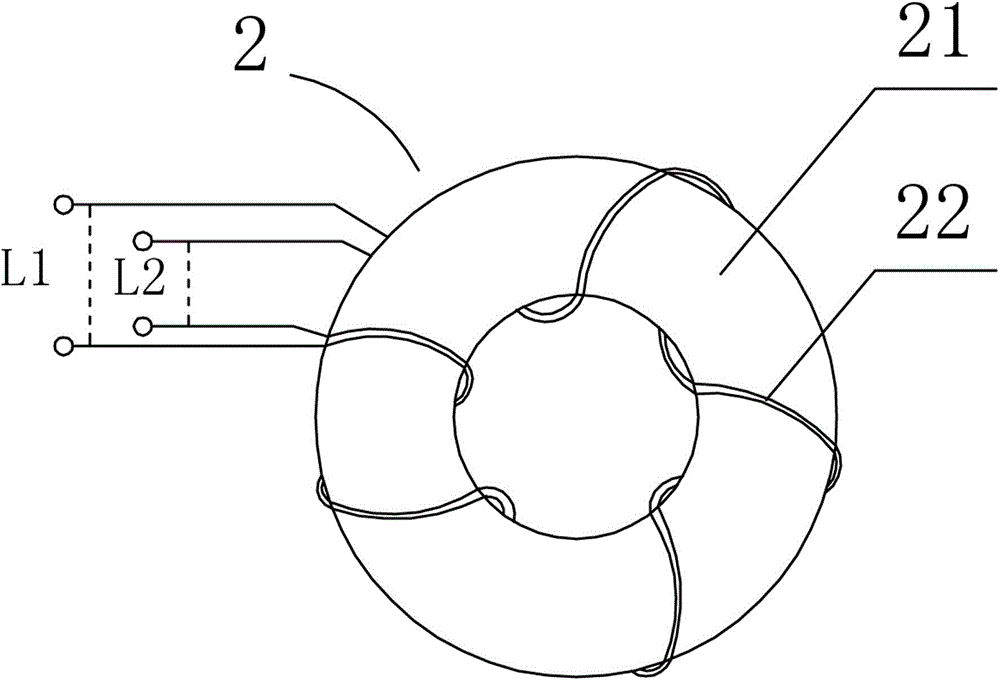

[0022] Such as figure 1 , figure 2 and image 3 As shown, a zero-sequence current transformer includes an annular housing 1, a current transformer coil 2 and a mounting base 3, the annular housing 1 includes an annular housing base and an annular housing upper cover 12, and the annular housing base is provided with There is a current transformer coil slot 111, and the inner ring outer wall of the annular shell base extends backward to form a ferromagnetic conduit 112, which is used to shield the interference of the external magnetic field; the current transformer coil 2 includes an annular iron core 21 and a winding The coil 22 on the annular iron core 21, the coil 22 adopts a round copper enameled wire double wire and is wound on the annular iron core 21, and forms the secondary output winding L1 and the secondary side of the zero-seq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com