Bootstrap type charging circuit applied to high-voltage DC-DC (Direct Current-Direct Current) convertor

A DC-DC and charging circuit technology, applied in the direction of conversion equipment without intermediate conversion to AC, can solve the problems of inability to fully drive the main switch tube, slow charging speed of C0, and drop in bootstrap voltage, so as to improve the charging driving ability , Accelerate the charging speed and increase the working voltage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

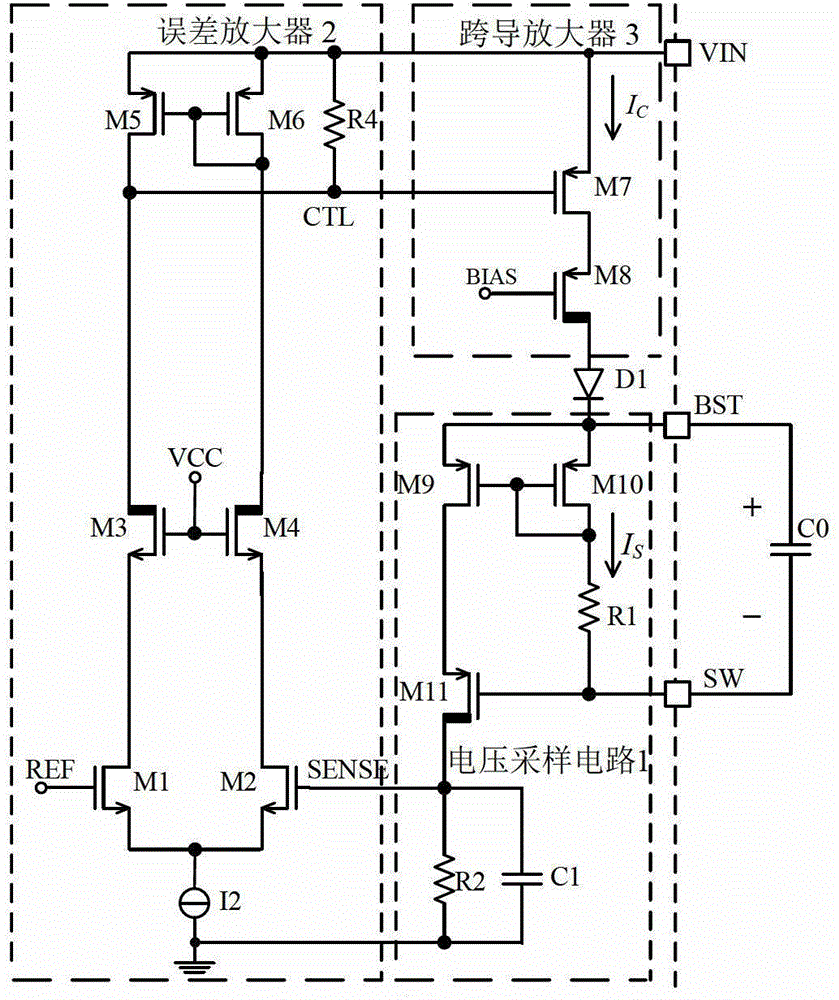

[0051] refer to image 3 , the voltage difference sampling circuit 1, error amplifier 2 and transconductance amplifier 3 that the bootstrap circuit of the present invention comprises, its specific circuit structure is as follows:

[0052] The voltage difference sampling circuit 1 of the present invention includes a high-voltage PMOS transistor M11 with a withstand voltage greater than 12V between the source and the drain, low-voltage PMOS transistors M9 and M10, resistors R1 and R2, and a capacitor C1;

[0053] The source of the low-voltage PMOS transistor M9 and M10 is connected, and as the input terminal A of the voltage difference sampling circuit 1, it is connected to the output pin BST of the DC-DC converter; its gate is connected to form an active current mirror structure ; The drain of the low-voltage PMOS transistor M10 is connected to the output pin BST of the DC-DC converter through the series resistor R1, and is used to sample the voltage difference V between the ou...

Embodiment 2

[0065] refer to Figure 4 , the voltage difference sampling circuit 1, error amplifier 2 and transconductance amplifier 3 that the bootstrap circuit of the present invention comprises, its specific circuit structure is as follows:

[0066] The voltage difference sampling circuit 1 and the transconductance amplifier 3 of the present invention are the same as those of the first embodiment.

[0067] The error amplifier 2 of the present invention includes high-voltage NMOS transistors M3, M4, M14, and M15 with withstand voltages greater than 12V between source and drain, low-voltage NMOS transistors M1, M2, M16, and M17, and low-voltage PMOS transistors M5, M6, and M12. , M13, resistor R4 and current source I2;

[0068] The low-voltage NMOS transistor M1 is connected to the source of M2 to form a differential pair, which is connected to the current source I2; its grid is respectively used as the input terminal E and the input terminal D of the error amplifier 2, and the input ter...

Embodiment 3

[0075] refer to Figure 5 , the voltage difference sampling circuit 1, error amplifier 2 and transconductance amplifier 3 that the bootstrap circuit of the present invention comprises, its specific circuit structure is as follows:

[0076] The voltage difference sampling circuit 1 and the transconductance amplifier 3 of the present invention are the same as those of the first embodiment.

[0077] The error amplifier 2 of the present invention includes high-voltage NMOS transistors M3, M4, M14, and M15 with withstand voltages greater than 12V between source and drain, low-voltage NMOS transistors M1, M2, M16, and M17, and low-voltage PMOS transistors M5, M6, and M12. , M13, resistor R4 and current source I2;

[0078] The low-voltage NMOS transistor M1 is connected to the source of M2 to form a differential pair, which is connected to the current source I2; its grid is respectively used as the input terminal E and the input terminal D of the error amplifier 2, and the input ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com